A kind of preparation method of dyeing sealing hardener for concrete

A hardening agent and concrete technology, which is applied in the field of building materials, can solve the problems of small application options and changing the appearance color, etc., and achieve the effects of reducing metal ion content, improving surface gloss and hydrophobicity, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

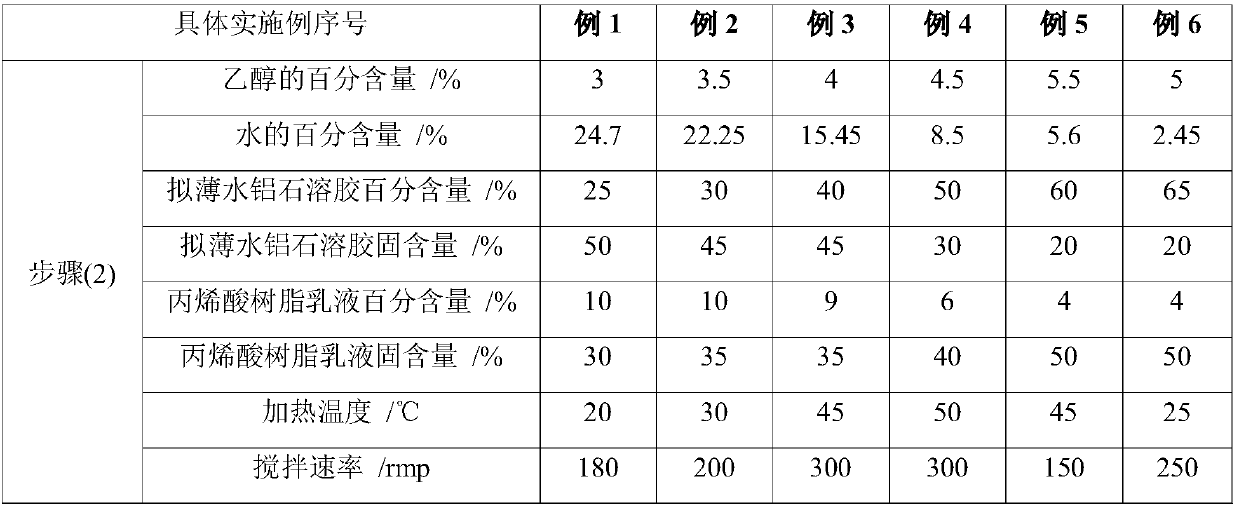

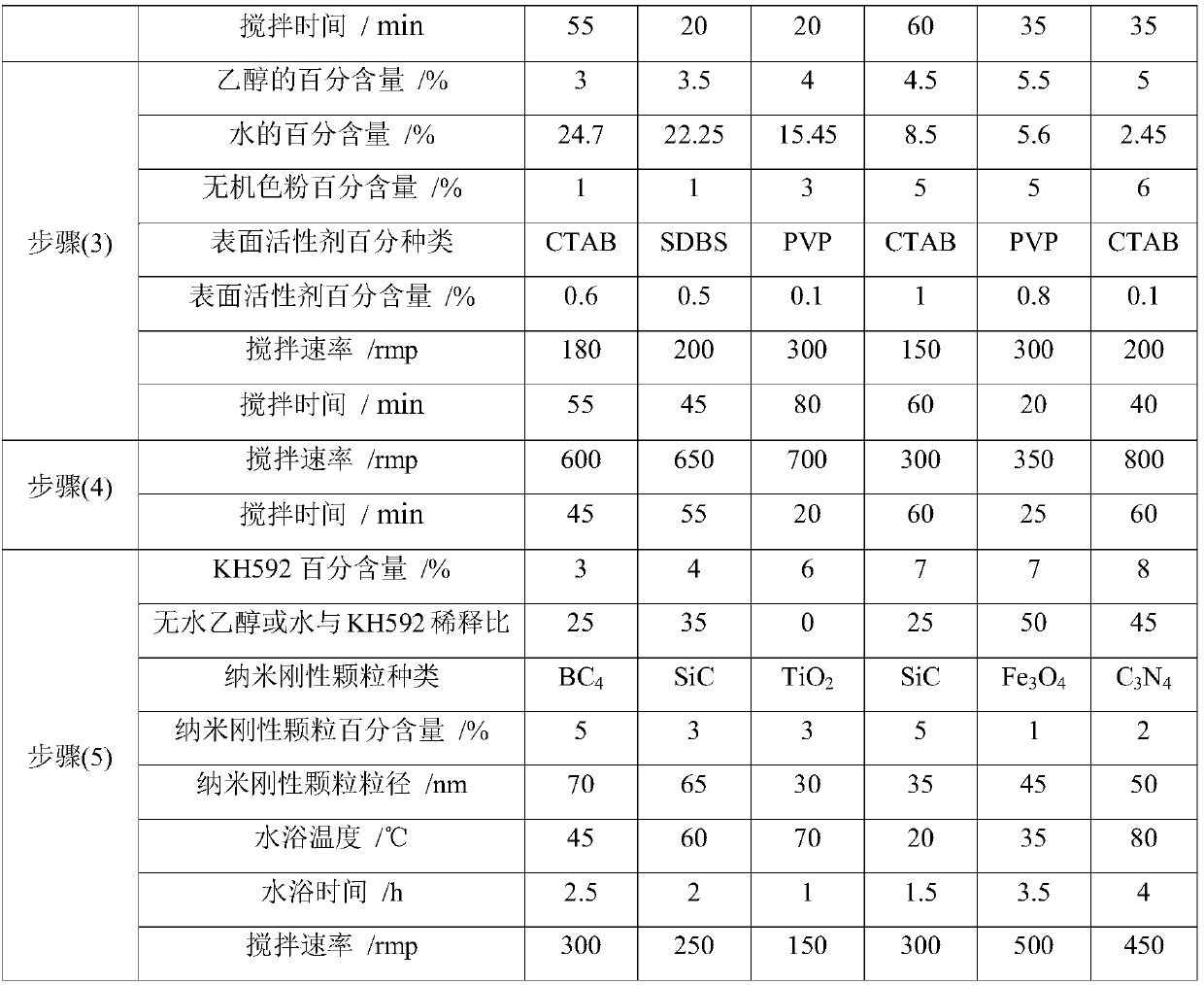

[0025] The present invention will be described in further detail below in conjunction with the examples, but those skilled in the art will understand that the following examples are only used to illustrate the present invention, and should not be considered as limiting the scope of the present invention.

[0026] The dyed seal hardener for concrete described in the present invention is formed by mixing the following raw material components in mass percentage: 25%-65% of pseudo-boehmite sol, 4%-10% of acrylic resin emulsion, surface 0.1% to 1% of active agent, 3% to 8% of silane coupling agent, 1% to 5% of rigid nano particles, 1% to 6% of inorganic toner, 6% to 11% of ethanol, and the balance is distilled water; Nano rigid particles are SiC, BC 4 、C 3 N 4 , Fe 3 o 4 or TiO 2 one or a combination of several.

[0027] The preparation method of the dyed sealing hardener for concrete comprises the following steps:

[0028] (1) Weigh each component according to the following...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| penetration depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com