Oil mark polymer and preparation method and application thereof

A technology for polymers and oils, applied in lubricating compositions, petroleum industry, etc., can solve problems such as blanks, achieve the effect of being difficult to imitate and improve the anti-counterfeiting level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0028] Preparation of Polymer 1

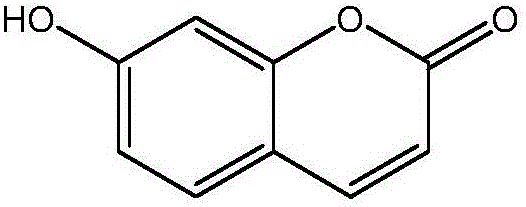

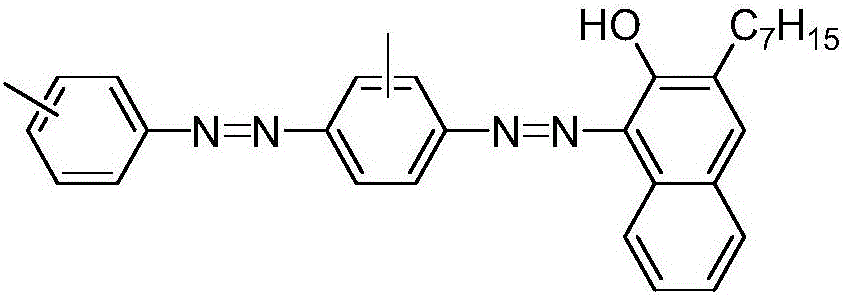

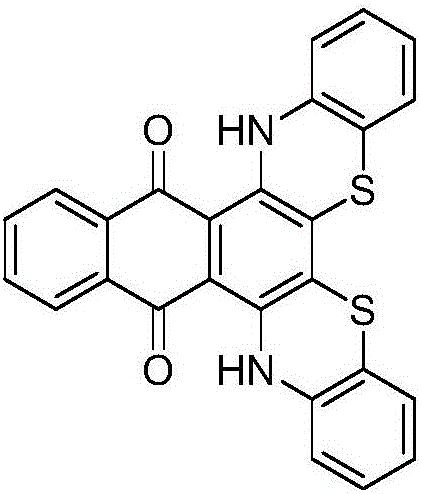

[0029] Polymer 1 is a linear polyisoprene containing coumarin groups. That is, the polymer template of polymer 1 is linear polyisoprene, and the labeling group is a fluorescent coumarin group. The structure is shown in the following formula, and the linking method adopted is "click" chemistry.

[0030]

[0031] The specific reaction steps of the experiment are as follows:

[0032] (1) Preparation of linear polyisoprene (L-PB)

[0033] The isoprene that has been pre-removed by n-BuLi is vaporized and introduced into cyclohexane to form a cyclohexane solution of isoprene (monomer:solvent=1:8, w / w=1: 8), and then introduce 100ml of cyclohexane solution into the polymerization bottle that has been evacuated-baked-argoned three times with high-purity argon, and then placed in a 50°C constant temperature water bath to preheat for 10min. Add 0.4ml of n-BuLi to kill impurities in the bottle, then quickly add 5.1ml of n-BuLi to initiate the polym...

Embodiment 2

[0051] Preparation of Polymer 2

[0052] Polymer 2 is a four-armed star polyisoprene containing coumarin groups

[0053] Reactive polyisoprene PI-Li in the preparation of repeated polymer 1 + Synthetic steps of , first add metered SiCl after reacting for 3h 4 (nSiCl 4 / nLi=1 / 4), coupled at 50° C. for 4 h, adding the terminator isobutanol, coagulated with ethanol to sink the gel, and dried in a vacuum oven to constant weight. A series of steps of epoxidation-ring-opening-bromination-azidation-"click" chemical reaction in the preparation process of polymer 1 was repeated to synthesize four-armed star polyisoprene containing coumarin groups. GPC characterization results are as follows, M w =8800, M w / M n =1.04,f w = 4, f w represents the number of polymer arms.

Embodiment 3

[0055] Preparation of Polymer 3

[0056] Polymer 3 is a comb polyisoprene containing coumarin groups.

[0057] Linear comb polyisoprene is obtained by coupling active polyisoprene chains with refined linear polyisoprene epoxy coupling agent. Repeat the synthesis steps of active polyisoprene in the preparation of polymer 1, add a refined solution of known concentration, couple at 50°C for 4 hours, and dry the sample in a vacuum oven to constant weight to obtain linear branched polyisoprene The crude product of alkenes was fractionated by precipitation to remove uncoupled oligomers. A series of steps of epoxidation-ring-opening-bromination-azidation-"click" chemical reaction in the preparation process of polymer 1 was repeated to synthesize star-shaped comb polyisoprene containing coumarin groups. GPC characterization results are as follows, Mw=7000, Mw / Mn=1.05, fw=4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com