Polyacid-graphene composite material and preparation method and application thereof

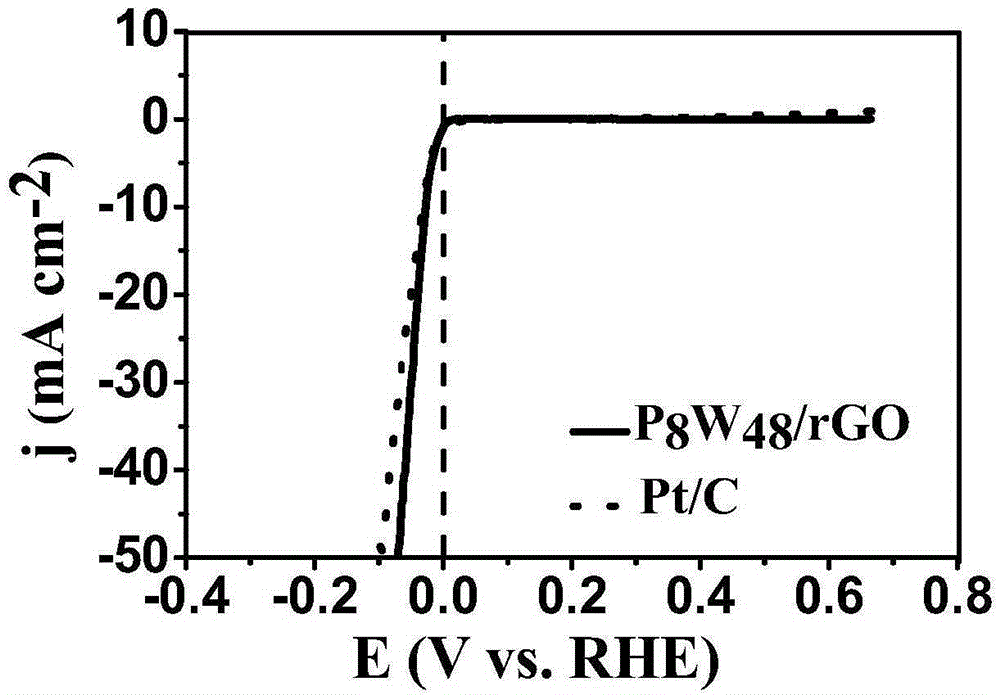

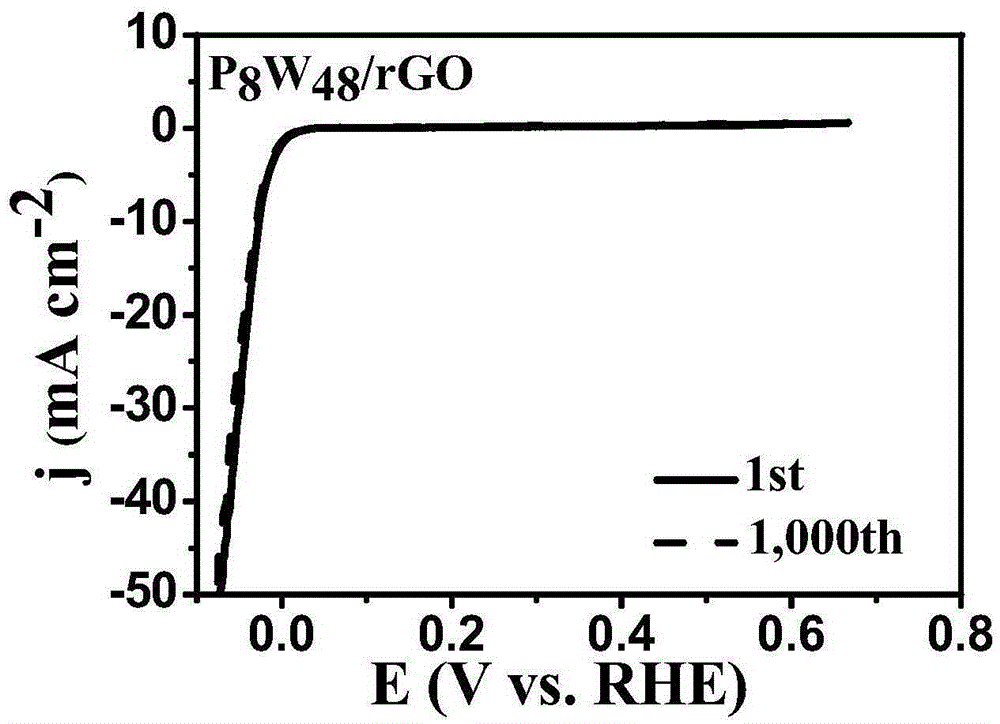

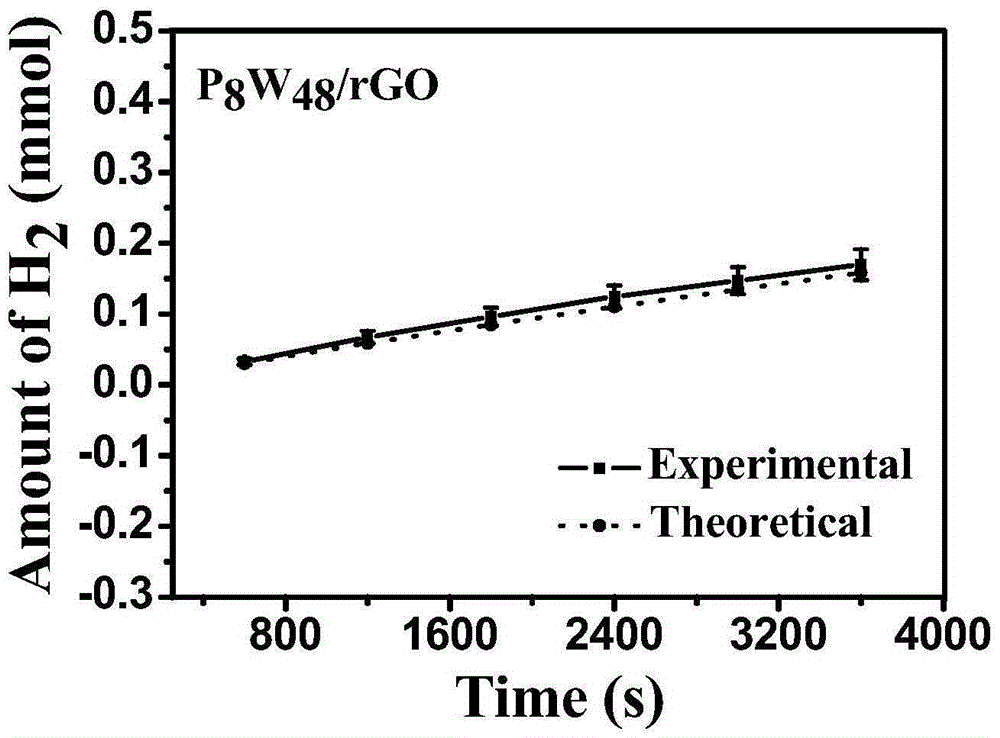

A composite material and graphene technology, applied in the field of clean energy, can solve problems such as ultraviolet light pollution, and achieve the effects of high electrocatalytic activity, low overpotential, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Polyacid [H 7 P 8 W 48 o 184 ] 33 – (P 8 W 48 ) (15mL, 1.6mM) and GO (15mL, 0.6mg mL -1 ) were simultaneously dispersed and dissolved in sulfuric acid solution (pH=1.0), and then electrolytic reduction was carried out at the potential of -0.65V vs. SCE to obtain polyacid (P 8 W 48 (16e - )), followed by P 8 W 48 (16e - ) can reduce GO to prepare graphene (rGO) materials. At the same time, P 8 W 48 (16e - ) back to P 8 W 48 , and adsorbed on the surface of rGO, that is, polyacid and graphene composite (P 8 W 48 / rGO).

Embodiment 2

[0022] Polyacid [H 7 P 8 W 48 o 184 ] 33 – (P 8 W 48 ) (15mL, 2mM) and GO (15mL, 0.6mg mL -1 ) were simultaneously dispersed and dissolved in sulfuric acid solution (pH=1.0), and then electrolytic reduction was carried out at the potential of -0.65V vs. SCE to obtain polyacid (P 8 W 48 (16e - )), followed by P 8 W 48 (16e - ) can reduce GO to prepare graphene (rGO) materials. At the same time, P 8 W 48 (16e - ) back to P 8 W 48 , and adsorbed on the surface of rGO, that is, polyacid and graphene composite (P 8 W 48 / rGO).

Embodiment 3

[0024] Polyacid [H 7 P 8 W 48 o 184 ] 33 – (P 8 W 48 ) (15mL, 2mM) and GO (15mL, 1.0mg mL -1 ) were simultaneously dispersed and dissolved in sulfuric acid solution (pH=1.0), and then electrolytic reduction was carried out at the potential of -0.65V vs. SCE to obtain polyacid (P 8 W 48 (16e - )), followed by P 8 W 48 (16e - ) can reduce GO to prepare graphene (rGO) materials. At the same time, P 8 W 48 (16e - ) back to P 8 W 48 , and adsorbed on the surface of rGO, that is, polyacid and graphene composite (P 8 W 48 / rGO).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com