Method for extracting lignin from black liquor

A technology of lignin and black liquor, which is applied in the regeneration of pulping liquid, textiles and papermaking, papermaking, etc., can solve the problems of low purity of lignin products, large amount of acid waste water, high environmental protection treatment cost, and achieve extraction adaptability. Strong, reduce acid consumption, reduce the effect of acid wastewater discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is further described in detail in conjunction with the embodiments of the present invention.

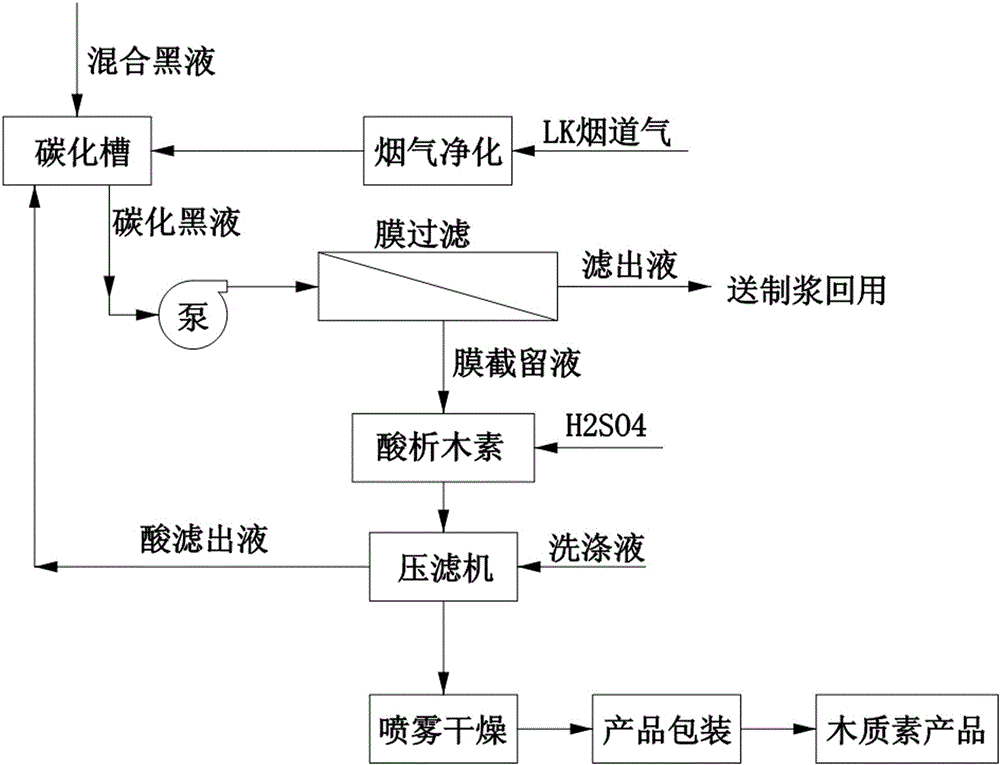

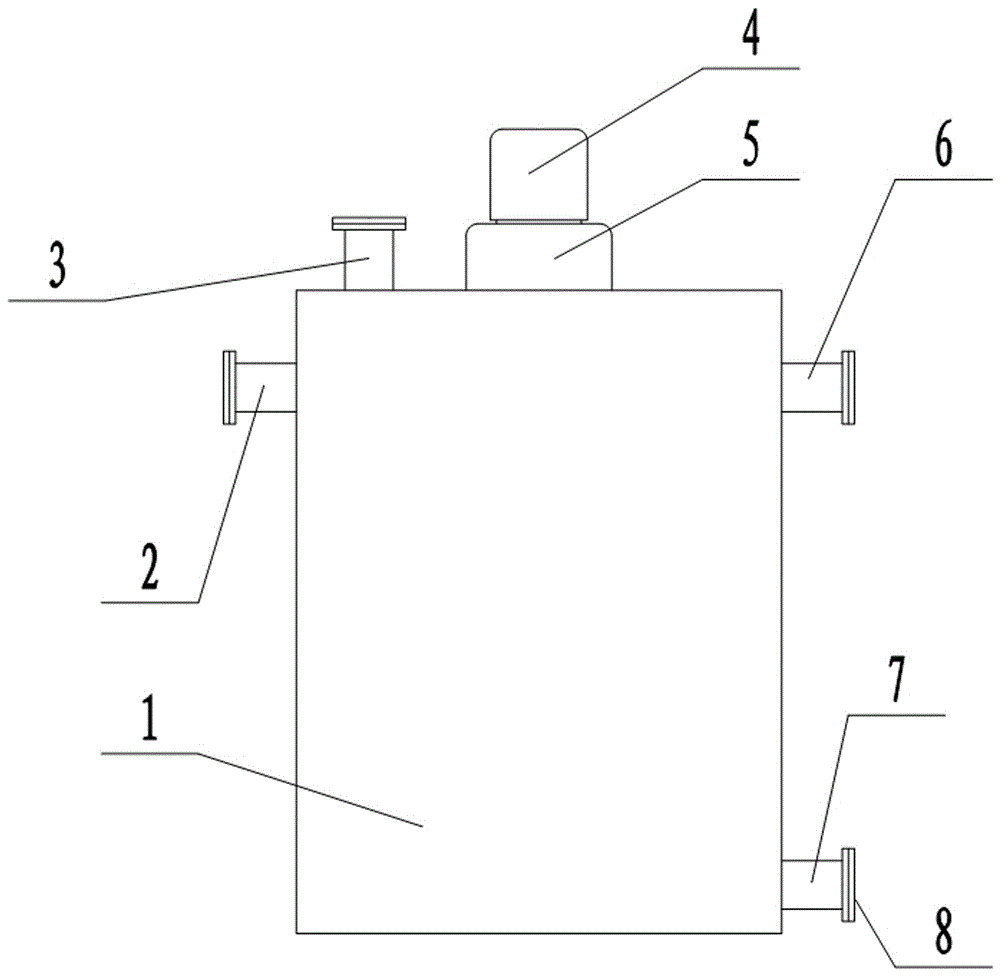

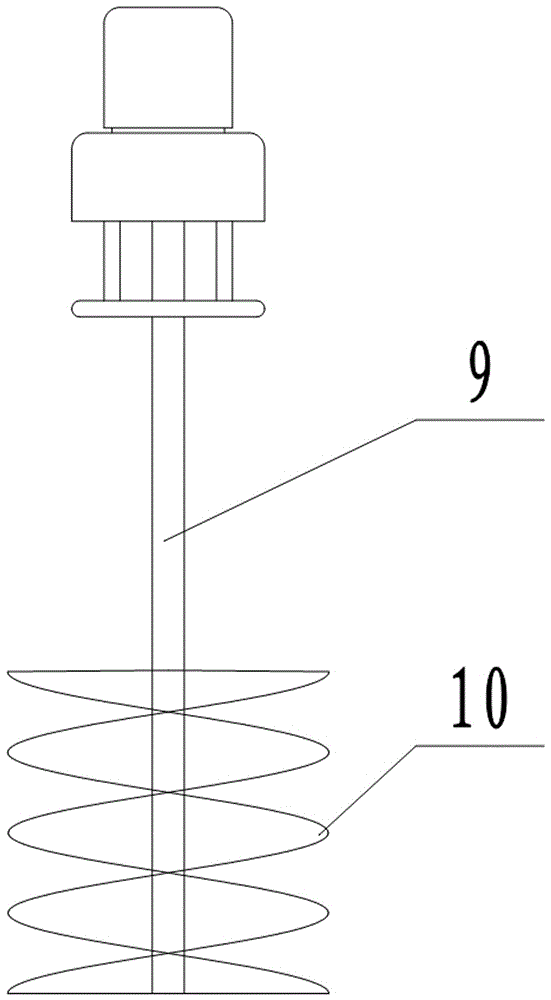

[0043] see Figure 1-4 Shown, a kind of method for extracting lignin in black liquor, described method comprises the following steps:

[0044] (1) Purify the flue gas of the kiln, pass the flue gas of the kiln through the three-stage furnace gas purification tower to remove dust and impurities, and after purification, the clean CO 2 The gas is respectively pressed into the inner bottom of the carbonization tanks at all levels in the carbonization tank group through the pipeline, and the clean CO 2 The gas emerges from the bottom of the carbonization tank;

[0045] (2) Black liquor pretreatment, the mixed black liquor sent from the pulping workshop is continuously sent to the carbonization tank group, and the mixed black liquor overflows step by step in the carbonization tank group from the first level to the higher level, and the carbonization tank Uni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com