Road inspection well structure and construction method thereof

A construction method and inspection well technology, which are applied in basic structure engineering, underwater structures, artificial islands, etc., can solve the problems of increasing construction difficulty, easily damaged well blocks, and difficult to clean up asphalt pavement, and improve construction efficiency. , the workload is reduced, the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

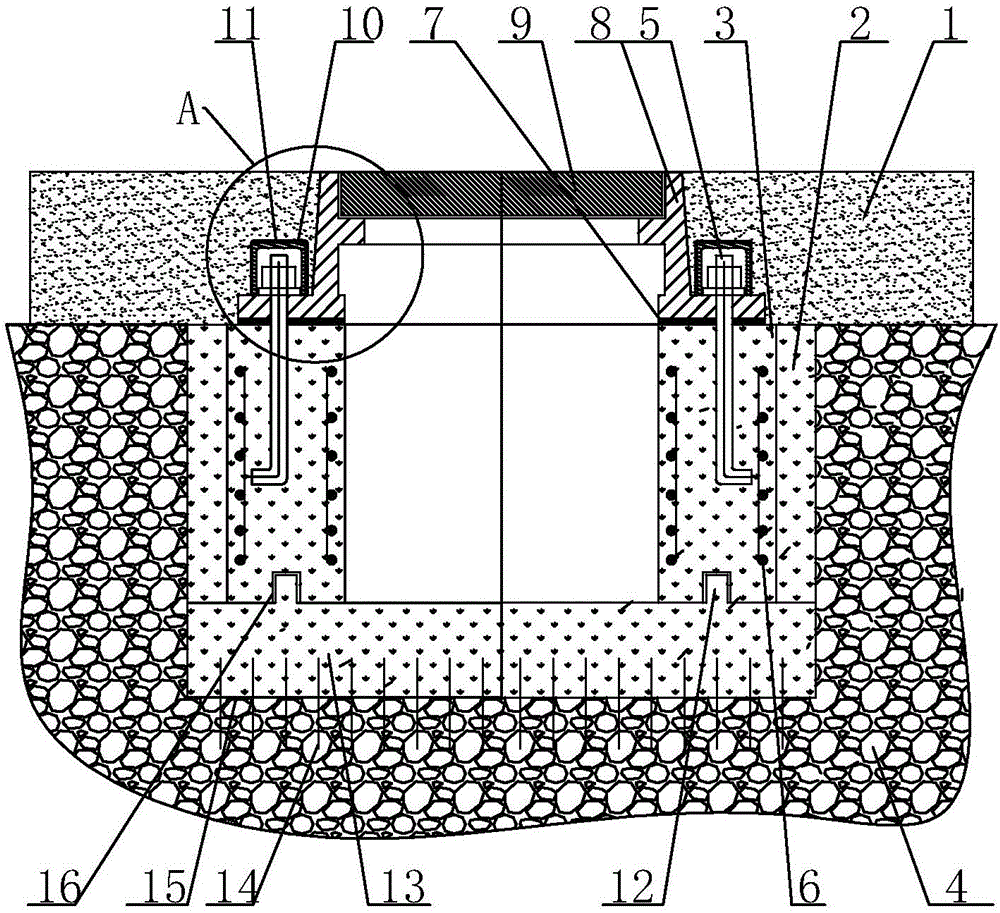

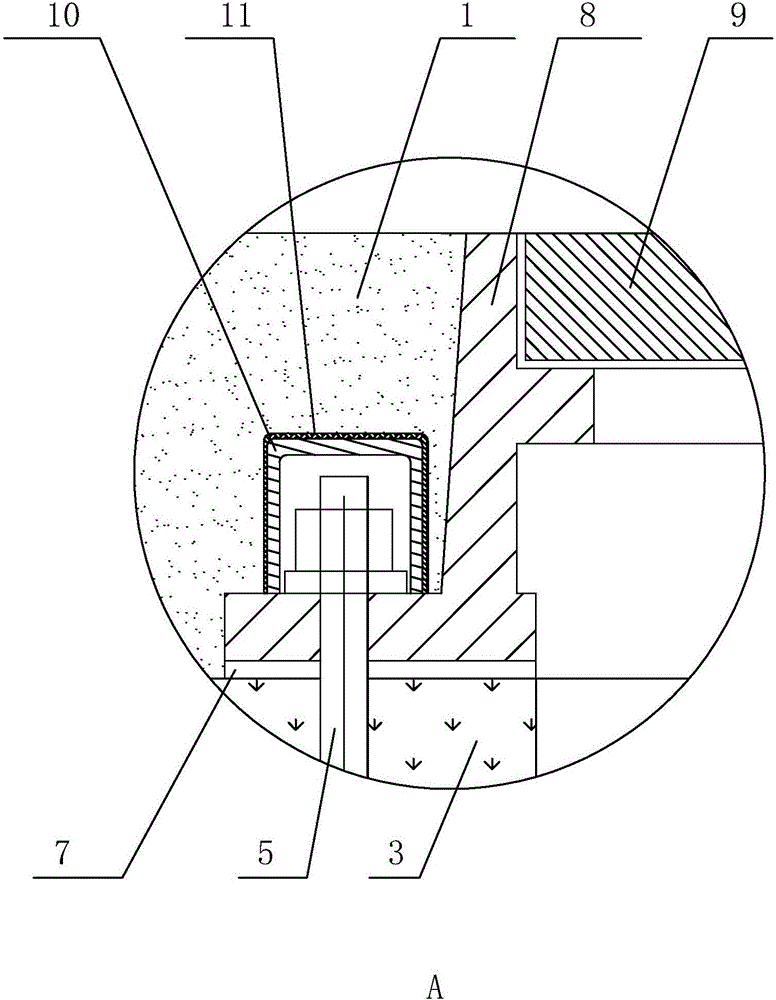

[0038] Embodiment: A road inspection well structure, which is mainly composed of a well cover 9, a well base 8, a well shaft 3, and a base 13. Several vertical steel bars 14 are inserted and buried at the bottom of the excavated well pit 15, and the base 13 It is at the bottom of the well pit 15 and the steel bar 14 is exposed to the bottom surface of the well pit 15 and inserted into the base 13. A coaxial fixed ring 12 connected as a whole protrudes from the base 13; With the matching annular groove 16, the shaft 3 is fixed on the base 13 through the cooperation of the annular groove 16 at the bottom and the fixed ring 12; the top of the shaft 3 is provided with a bolt 5 protruding from the inside, and the bolt 5 is arranged in an L shape. The seat 8 is coaxially fixed on the upper end of the wellbore 3 through bolts 5 and nuts. There is a cylindrical protective cover 10 with a height lower than the top surface of the well seat 8 outside each nut. A layer of polyester is adhe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com