Whole-dry type system for producing oil and gas in water and working method of whole-dry type system for producing oil and gas in water

A production system, fully dry technology, applied in the direction of earthwork drilling, wellbore/well components, production fluid, etc., can solve the problems of large influence of oil and gas development operations, low space utilization rate, difficult construction, etc., to achieve improved Efficiency and economy, improved space utilization, and reduced maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] The present invention will be further described below with reference to the accompanying drawings.

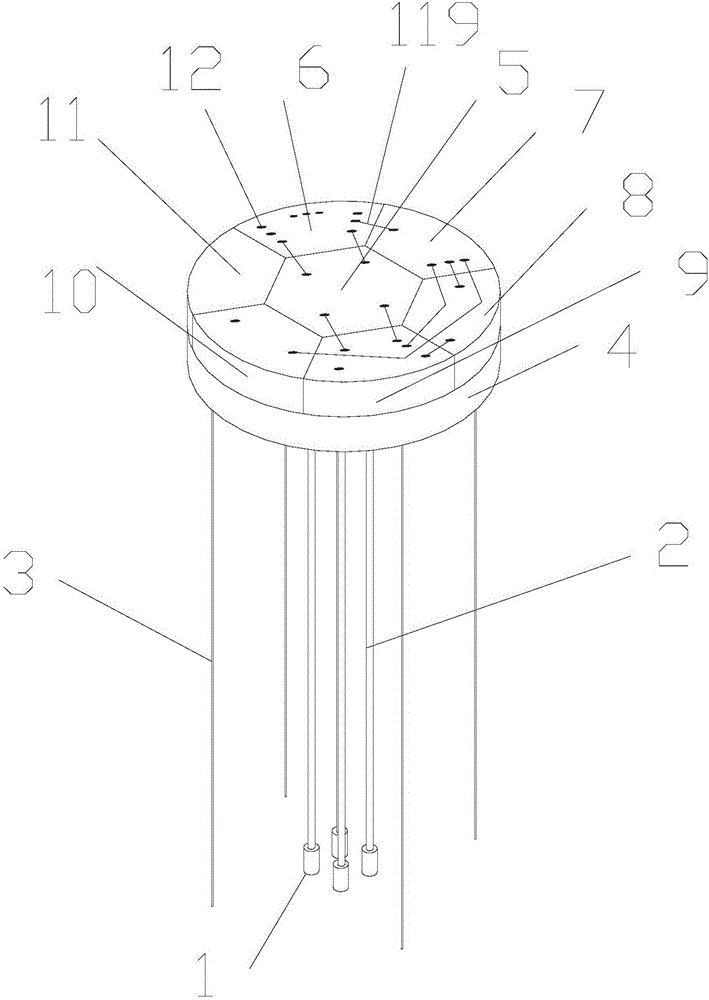

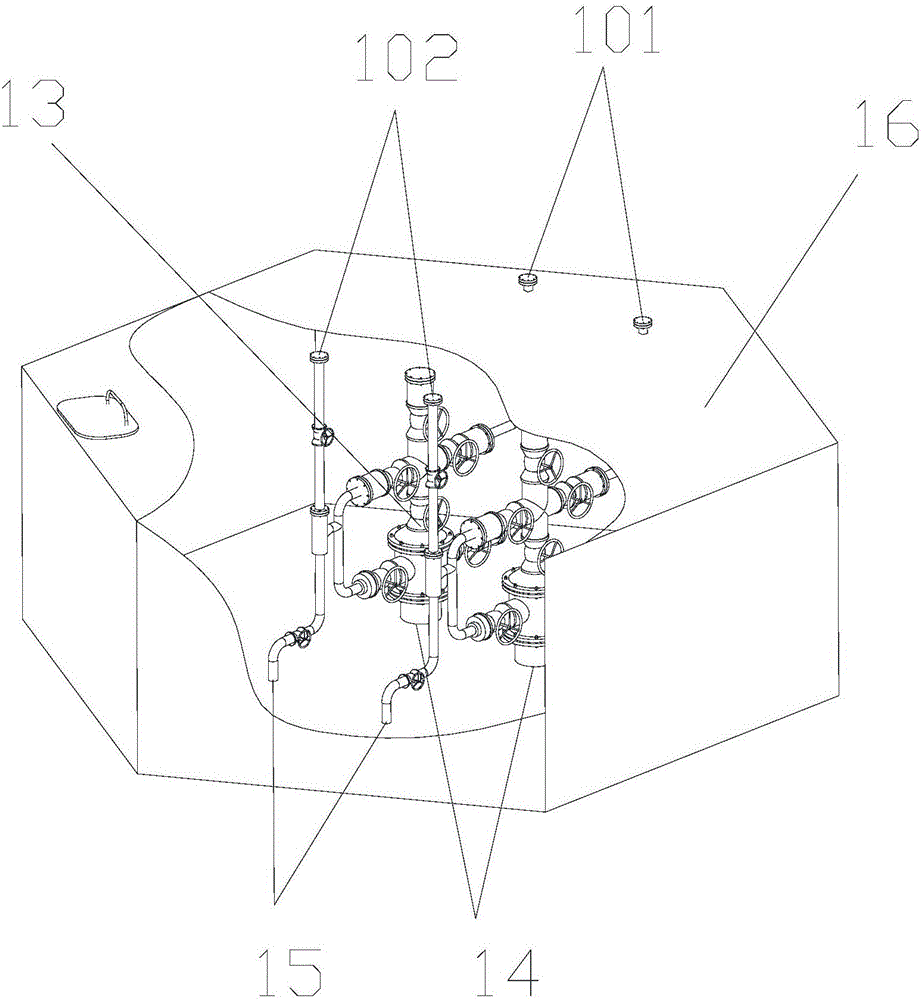

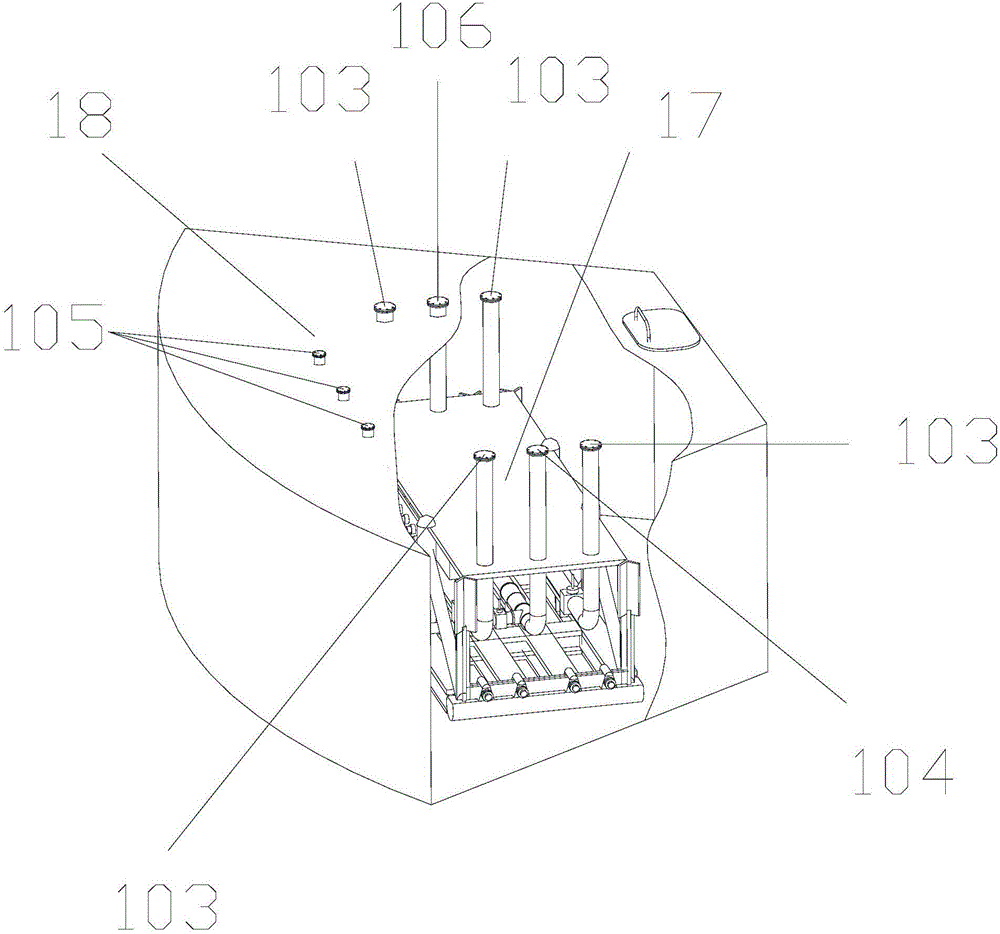

[0084] Such as Figure 1-11 As shown, the fully dry underwater oil and gas production system includes a functional unit, an underwater platform 4, an underwater wellhead 24, a subsea wellhead 1, a rigid riser 2, and a tension cable 3; the functional unit is installed and fixed on the underwater platform 4 , including one a-type unit and 6 b-type units 34, the horizontal plane shape of the a-type unit is an equilateral hexagon, including the dry oil recovery and reinjection unit 5, the b-type unit 34 horizontal plane shape is fan-shaped, 6 A b-type unit 34 has the same external outline size and shape, surrounds the a-type unit periphery, and its projection on the horizontal plane forms a ring whose outer ring is a circle and the inner ring is an equilateral hexagon; the six b-type units 34 are respectively It is a dry collection unit 6, a dry separation unit 7, a dry pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com