Auxiliary combustion device for diesel engine

A technology for diesel engines and gas devices, which is applied to engine components, combustion engines, machines/engines, etc., can solve problems such as limiting effective application, and achieve the effect of compact structure and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

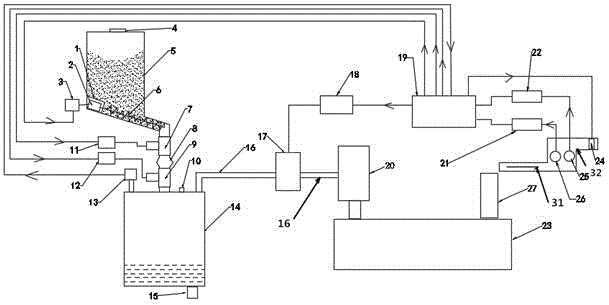

[0031] A combustion-supporting device for a diesel engine, including a feeding device, a gas supply and gas consumption device, and a measurement and control device;

[0032] The feeding device includes a feeding motor 2, a motor governor 3, an oxygen generator silo 5, a screw conveying rod 6, a primary electromagnetic door 7, a small dump bin 8 and a secondary electromagnetic door 9; the top of the oxygen generator silo 5 There is a feeding port 4, the feeding motor 2 and the screw conveying rod 6 are arranged at the bottom of the oxygen generator hopper 5, and the bottom of the oxygen generator hopper 5 is inclined; one end of the screw conveying rod 6 is connected with the feeding motor 2, and the other end is connected with a The first-level electromagnetic door 7 is connected, and the first-level electromagnetic door 7 is connected with the second-level electromagnetic door 9 through the dump small bin 8; the motor governor 3 is arranged outside the oxygen generator silo 5...

Embodiment 2

[0037] A combustion-supporting device for a diesel engine, including a feeding device, a gas supply and gas consumption device, and a measurement and control device;

[0038] The feeding device includes a feeding motor 2, a motor governor 3, an oxygen generator silo 5, a screw conveying rod 6, a primary electromagnetic door 7, a small dump bin 8 and a secondary electromagnetic door 9; the top of the oxygen generator silo 5 There is a feeding port 4, the feeding motor 2 and the screw conveying rod 6 are arranged at the bottom of the oxygen generator hopper 5, and the bottom of the oxygen generator hopper 5 is inclined; one end of the screw conveying rod 6 is connected with the feeding motor 2, and the other end is connected with a The first-level electromagnetic door 7 is connected, and the first-level electromagnetic door 7 is connected in a straight line with the second-level electromagnetic door 9 through the dump small bin 8; the motor governor 3 is arranged outside the oxyg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com