Hydraulic driving mechanism of crusher

A driving mechanism and crusher technology, applied in fluid pressure actuating devices, mechanical equipment, servo motors, etc., can solve the problems of large start-up impact, loud noise, time-consuming and labor-intensive crusher rotors, etc., to improve efficiency and reduce power consumption. , the effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

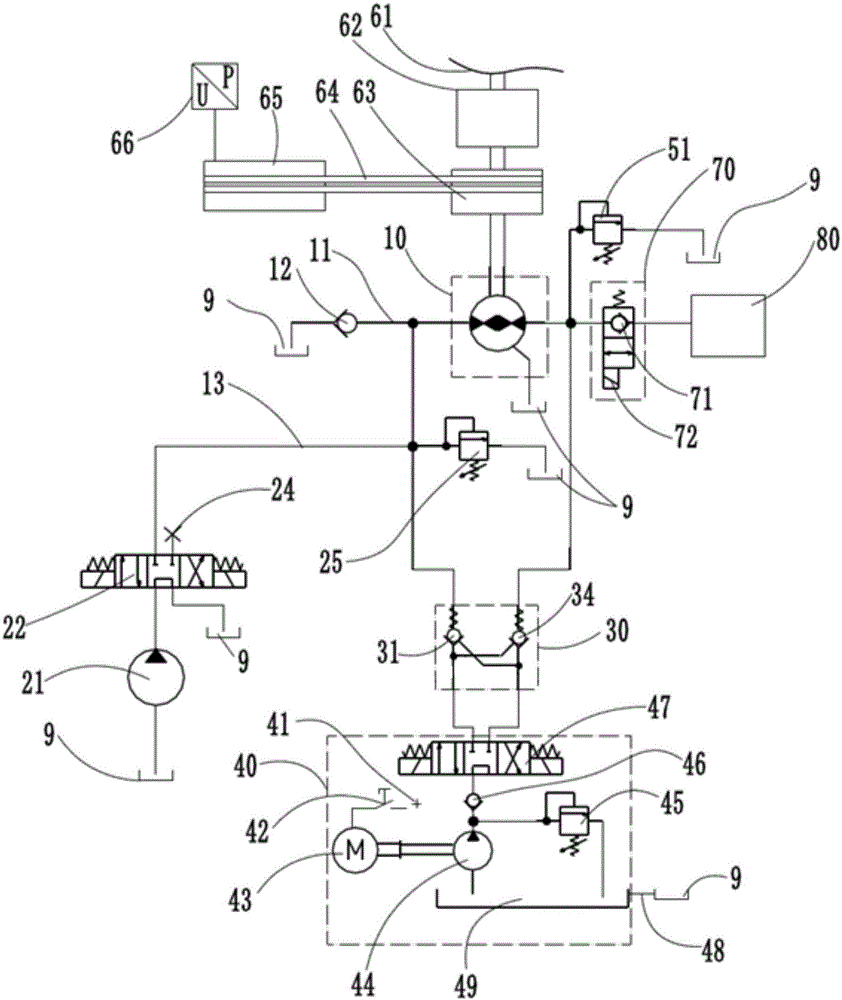

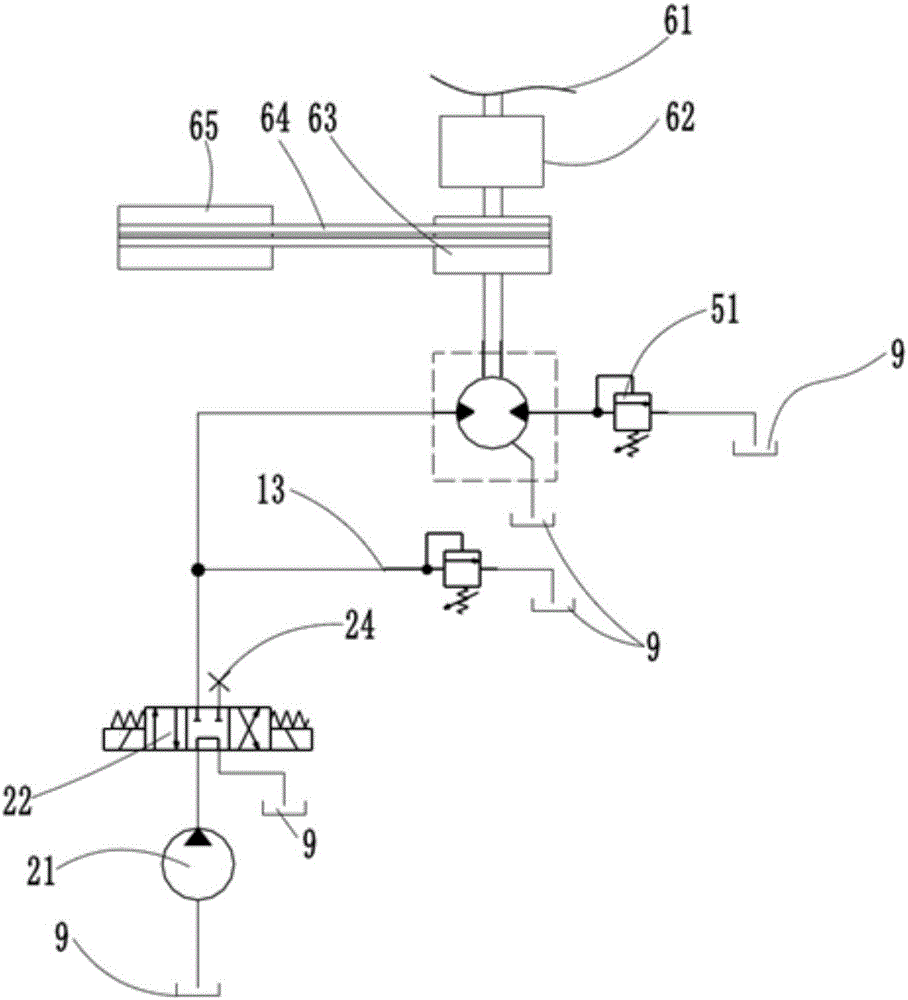

[0022] like Figure 2-3 As shown, the present invention discloses a hydraulic drive mechanism of a crusher, including a hydraulic motor 10, a running hydraulic pipeline 11, a starting hydraulic pipeline 13, a first hydraulic pump 21, a solenoid valve 22, an engine 61, a clutch 62, a rotational speed The sensor 66 and the first pulley 65, the hydraulic motor 10 is connected with the oil tank 9 through the operating hydraulic line 11, the hydraulic motor 10 is connected with the solenoid valve 22 through the starting hydraulic line 13, the first hydraulic pump 21 is connected with the solenoid valve 22, and the engine 61 The hydraulic motor 10 is driven to rotate by the clutch 62 , the rotational speed sensor 66 is used to detect the rotational speed of the rotor of the crusher, the rotational speed sensor 66 controls the clutch 62 to engage, the engine 61 drives the hydraulic motor 10 to rotate through the clutch 62 , and the hydraulic motor 10 drives the crushing through the fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap