Power-uninterrupted hydraulic gear shifting device

A shifting device, hydraulic technology, applied in the direction of transmission control, components with teeth, belt/chain/gear, etc., can solve the problems of complex structure, high manufacturing process requirements, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

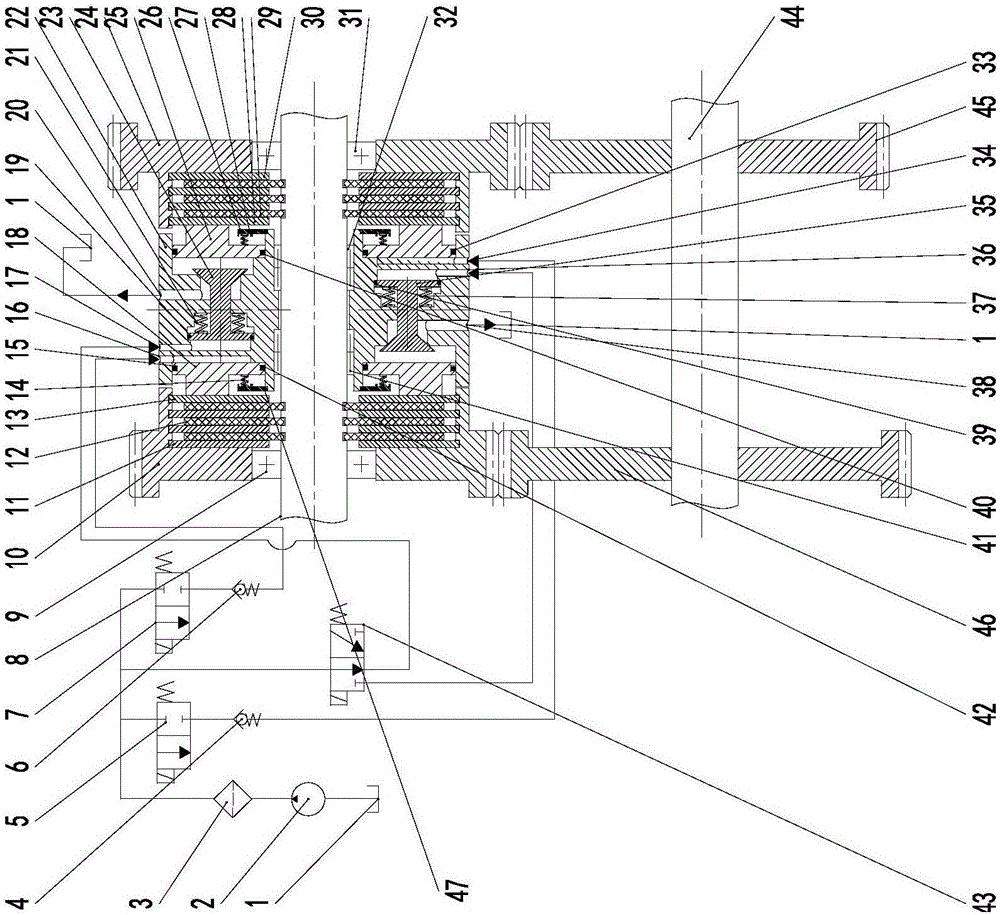

[0040] A power uninterrupted hydraulic shifting device is applied to a two-speed automatic transmission system of an electric vehicle to realize automatic switching between two gears.

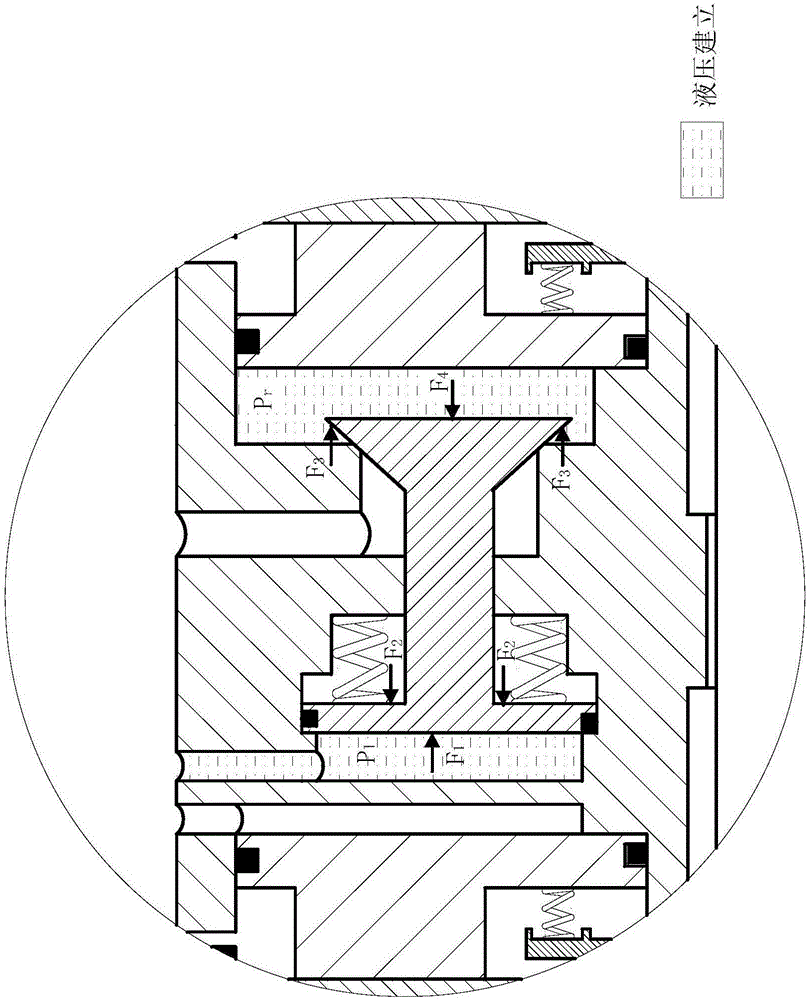

[0041] Such as figure 1 , 2 As shown, a power uninterrupted shifting device includes a fuel tank 1, an oil pump 2, a filter 3, a first electromagnetic reversing valve 7, a second electromagnetic reversing valve 5, a third electromagnetic reversing valve 43, a first one-way Valve 6, second one-way valve 4, input shaft 8, first gear 10, first steel plate 11, first friction plate 12, first pressure plate 13, first piston return spring 14, first piston return Spring seat 47, first piston inner seal ring 42, first piston outer seal ring 15, first piston oil inlet 16, first spool oil inlet 17, first piston 18, first linkage spool 23, first piston A linkage spool seal ring 19, a first linkage spool return spring 21, a first oil outlet 20, a second piston inner seal ring 40, a second piston outer sea...

Embodiment 2

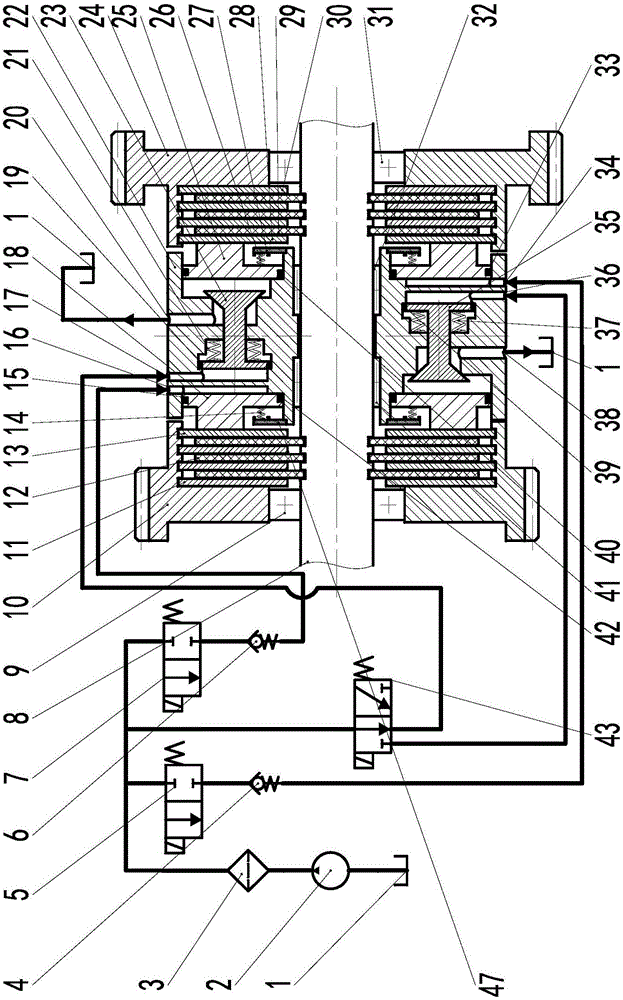

[0059] Such as image 3 As shown, in the application of electric vehicles, the input shaft 8 is connected to the output shaft of the motor, and the neutral gear can be realized by controlling the motor to stop, and there is no need for figure 2 The third solenoid selector valve 43 is shown. The first electromagnetic reversing valve 7 is connected to the first piston oil inlet 16 after connecting the first one-way valve 6, and the first spool oil inlet 17 is connected to the outlet of the first electromagnetic reversing valve 7; the second electromagnetic reversing valve 5 is connected to the second piston oil inlet 34 after being connected to the second one-way valve 4, and the second valve core oil inlet 36 is connected to the outlet of the second electromagnetic reversing valve 5. The first oil outlet 20 and the second oil outlet 38 are directly connected to the oil tank 1 . The first electromagnetic reversing valve 7 and the second electromagnetic reversing valve 5 are n...

Embodiment 3

[0062] Such as Figure 4 As shown, a power uninterrupted shifting device based on a planetary mechanism; the gearbox case 9 is fixed to the vehicle frame, and the case 9 is connected to the input shaft 32 through a bearing 8 . The first steel plate 10 is connected with the hydraulic cylinder 24 , and the first friction plate 11 is connected with the box body 9 . The second steel plate 26 is installed on the hydraulic cylinder 24, which is also the ring gear of the planetary mechanism. The second friction plate 25 is installed on the sun gear 28 of the planetary mechanism, and the sun gear 28 and the input shaft 32 are fixed. The planetary gear 27 is installed on the planetary carrier 29 through the planetary gear bearing, and the planetary carrier 29 provides power output. The structure of other components is basically the same as in Embodiment 1.

[0063] The number of teeth of sun gear 28 is z 1 , the number of teeth of the ring gear on the hydraulic cylinder 24 is z 2 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com