Heat pipe radiator with oblique heat-conducting surface

A technology of heat pipe radiator and heat conduction surface, which can be used in indirect heat exchangers, lighting and heating equipment, etc., and can solve the problems of low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

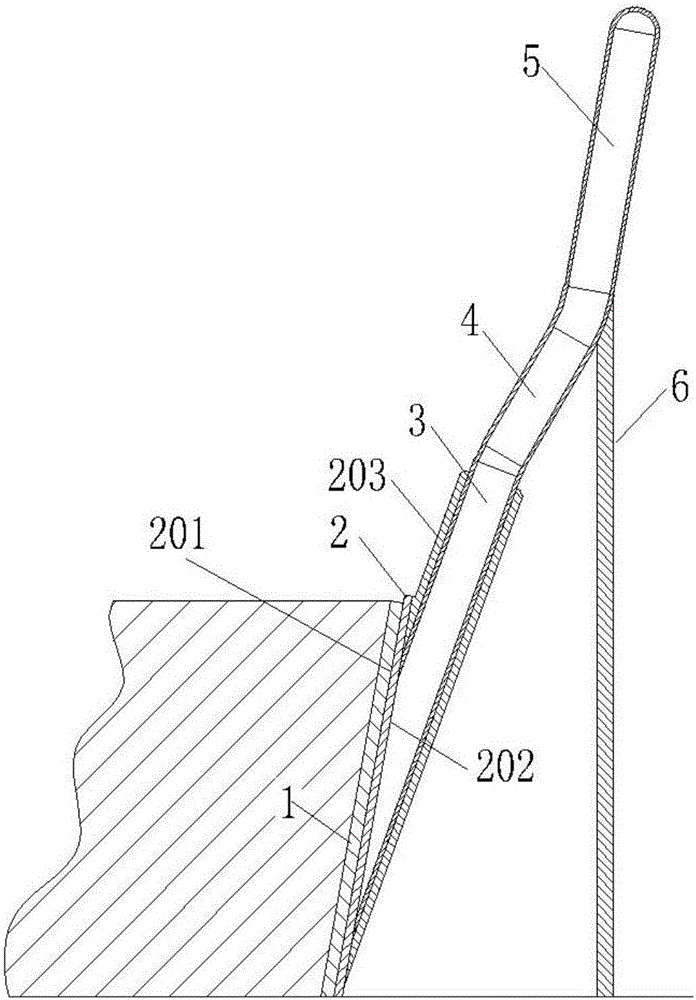

[0028] Example 1, Figure 11 It is a schematic diagram of embodiment 1, and the drawing surface is a sectional view, and the sectional plane is a vertical plane passing through the center line of the container 40 and parallel to the page; the working condition is; the inside of the container 40 needs to dissipate heat, and the heat dissipation part is carried out on the side of the conical surface of the container Heat dissipation; now adopt the heat pipe radiator on the inclined plane heat conduction surface, and the heat pipe radiator assembly 20 in the figure is to include figure 2 The combination of all parts except the heat pipe assembly, (thus, except as required in the text of this paragraph, figure 2 The parts in the Figure 11 No longer marked in), the heat pipe assembly adopts cross-section such as Figure 5The heat pipe assembly of the shown single heat pipe double-sided conformable slope heat-conducting surface heat pipe radiator; the heat-dissipating surface 4...

Embodiment 2

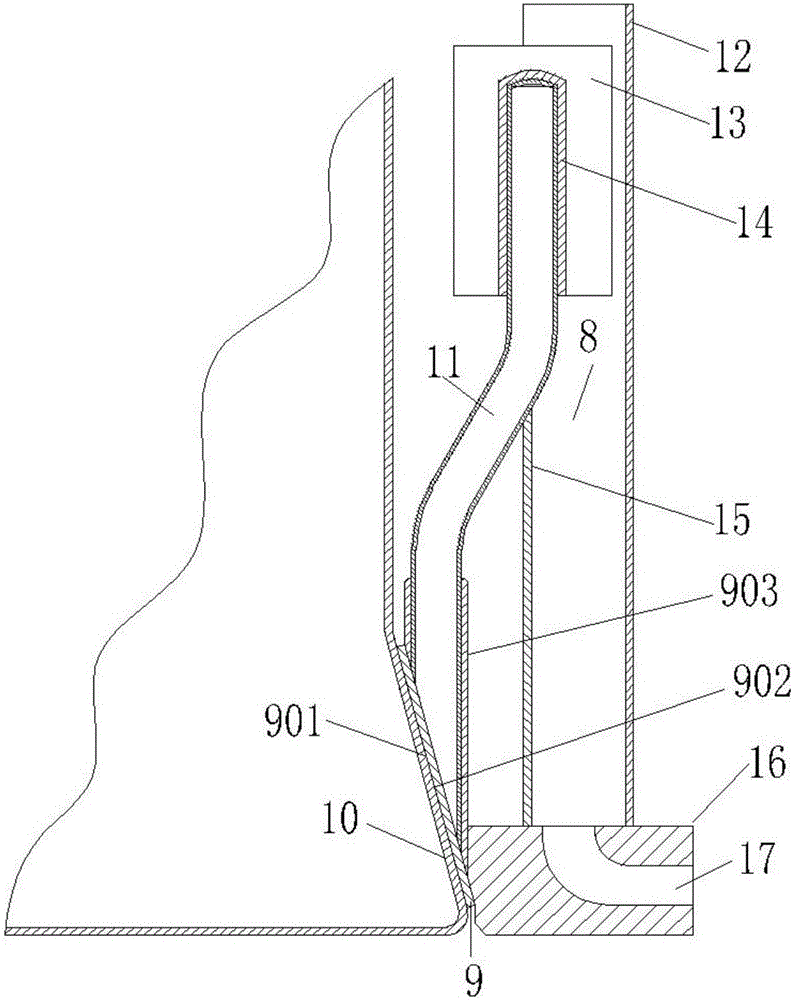

[0029] Example 2, Figure 12 It is a schematic diagram of embodiment 2, and the drawing is a sectional view, and the sectional plane is a vertical plane passing through the center line of the heat pipe and parallel to the page; Figure 12 The equipment cabinet 50 in the work is in relatively bad environment, so shell 54 adopts fully enclosed structure to strengthen protection; , the heat dissipation surface is an inclined plane, so the heat pipe radiator with an inclined plane heat conduction surface is used, and the heat pipe 18 is the same as figure 1 Combination of all parts except work object 1 and strut 6 or figure 2 The middle heat pipe 11 is similar to the heat pipe, wherein the area of the heat conduction surface of the heat conduction block 43 of the evaporating section in the contact direction with the working object is ≥ the area of the heat dissipation surface 42 of the heating element, and the entire area is kept in close contact, and the contact surface is ...

Embodiment 3

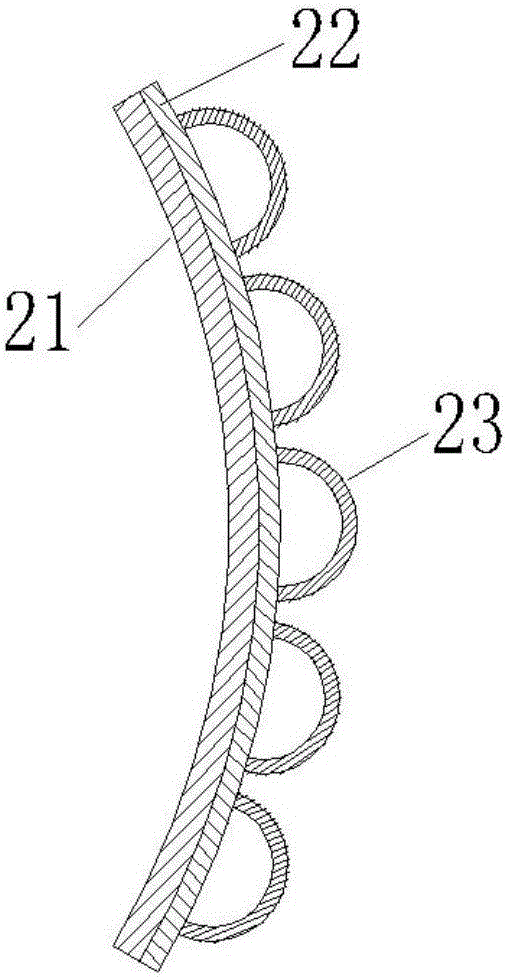

[0030] Example 3, Figure 13 It is a schematic diagram of embodiment 3, and the drawing is a sectional view, and the sectional plane is a vertical plane passing through the center line of the container 60 and parallel to the page; the working condition is that the inside of the container 60 needs to dissipate heat, and the heat is mainly concentrated in the lower part of the container. The heat dissipation surface 61 is an inverted cone; the heat pipe radiator on the inclined plane heat conduction surface is now used, and the heat pipe radiator assembly 67 is composed of figure 2 The combination of all parts except the heat pipe assembly, the cross section of the heat pipe assembly is as follows Figure 5 The heat pipe assembly of the shown single heat pipe double-sided conformable slope heat-conducting surface heat pipe radiator, the heat-dissipating surface 61 of the container 60 and the heat-conducting surface of the evaporation section heat-conducting block 69 of the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com