Method for acquiring bolted connection bonding surface stress distribution

A stress distribution and bonding surface technology, applied in special data processing applications, instruments, geometric CAD, etc., can solve problems such as large memory requirements, low computational efficiency, and limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

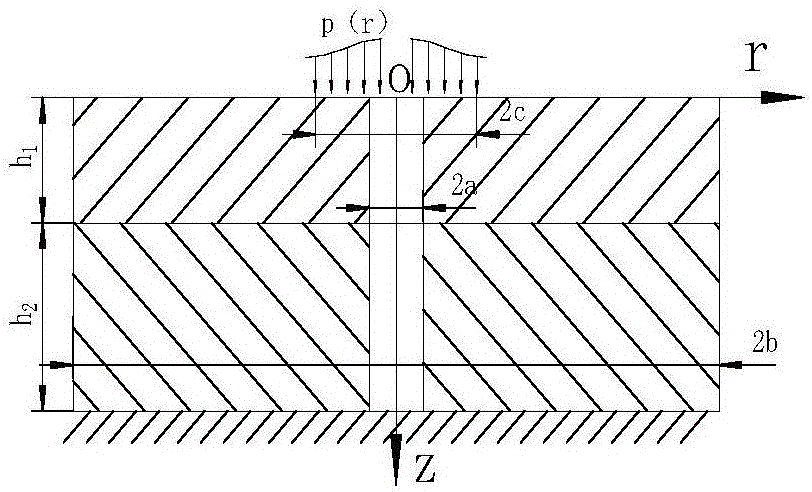

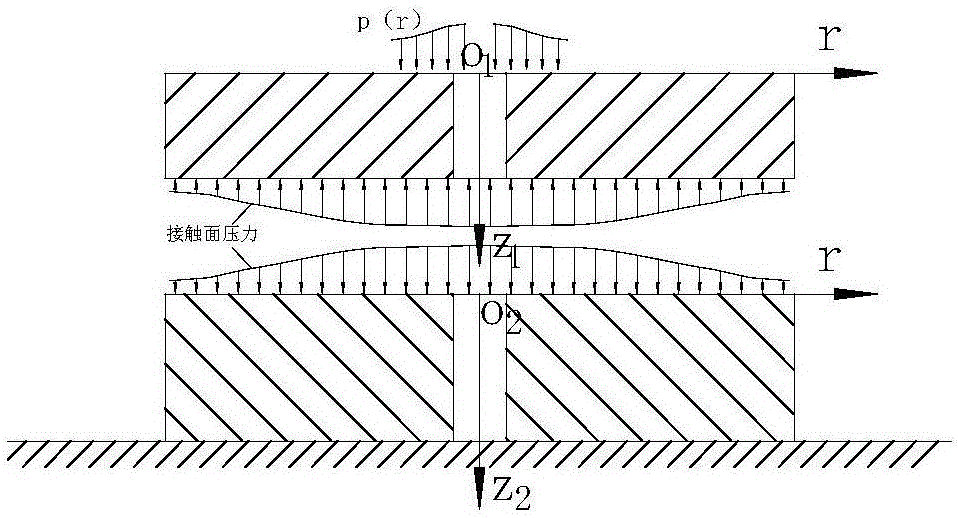

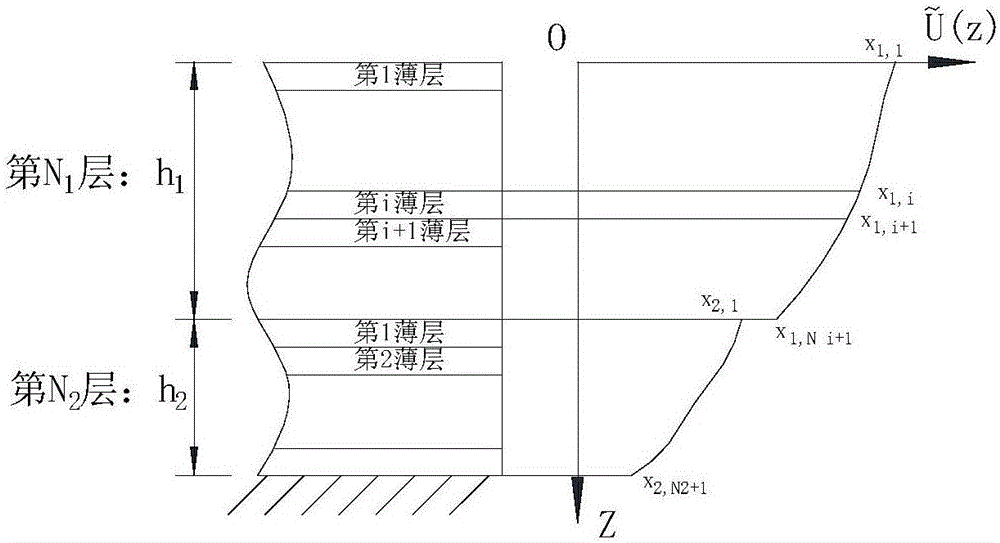

[0077] Such as Figure 1-Figure 6 As shown, a method to obtain the stress distribution of the joint surface of the bolted connection has the following steps:

[0078] S1. Test the bolted connection structure, each connected part and material parameters, including the thickness h of each connected part j , the bolt hole diameter 2a, the equivalent diameter of the area affected by the bolt load 2b, the pretightening force radius range a≤r≤c, and the corresponding elastic modulus E of each connected part j , Poisson's ratio ν i , shear modulus G j , Lamé constant λ j , where j∈(1,2,...,K), h 1 Corresponding to the thickness of the first connected part on which the pretightening force directly acts; take the center of the upper surface of the first connected part as the coordinate origin O, take the central axis of the connected part as the axis of symmetry z, and its direction is vertically downward, r The axis is along the horizontal direction, and the global cylindrical co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com