Three-phase integrated gas-insulated transmission line

A transmission line, gas insulation technology, applied in the direction of busbar/line layout, electrical components, cable installation, etc., can solve problems such as affecting the safe operation of busbars, large investment in thermal compensation devices, inability to absorb deformation, etc., to reduce the number of sealing surfaces , The effect of saving project cost and reducing the number of flange connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Such as Figure 10 As shown, a three-phase communal rigid gas insulated transmission line includes a straight section unit 2 and a compensation unit 4, each straight section unit 2 includes a shell filled with insulating gas and three straight conductors arranged inside the shell. The compensation unit includes an intermediate housing 42, two bellows 41 with flanges, a short flow piece 43, a limit piece 44, an insulating support and three straight conductors. The number of straight section units and compensation units is determined according to construction needs. There may be multiple straight section units and compensation units. The number and arrangement sequence of the combination are determined according to the terrain of the transmission line laying or the need to add ports. That is, n (n≥1) straight section units and m (m≥1) compensation units can be set, and in use, n straight section units 2 and m compensation units 4 are connected in pairs by flanges. The co...

Embodiment 2

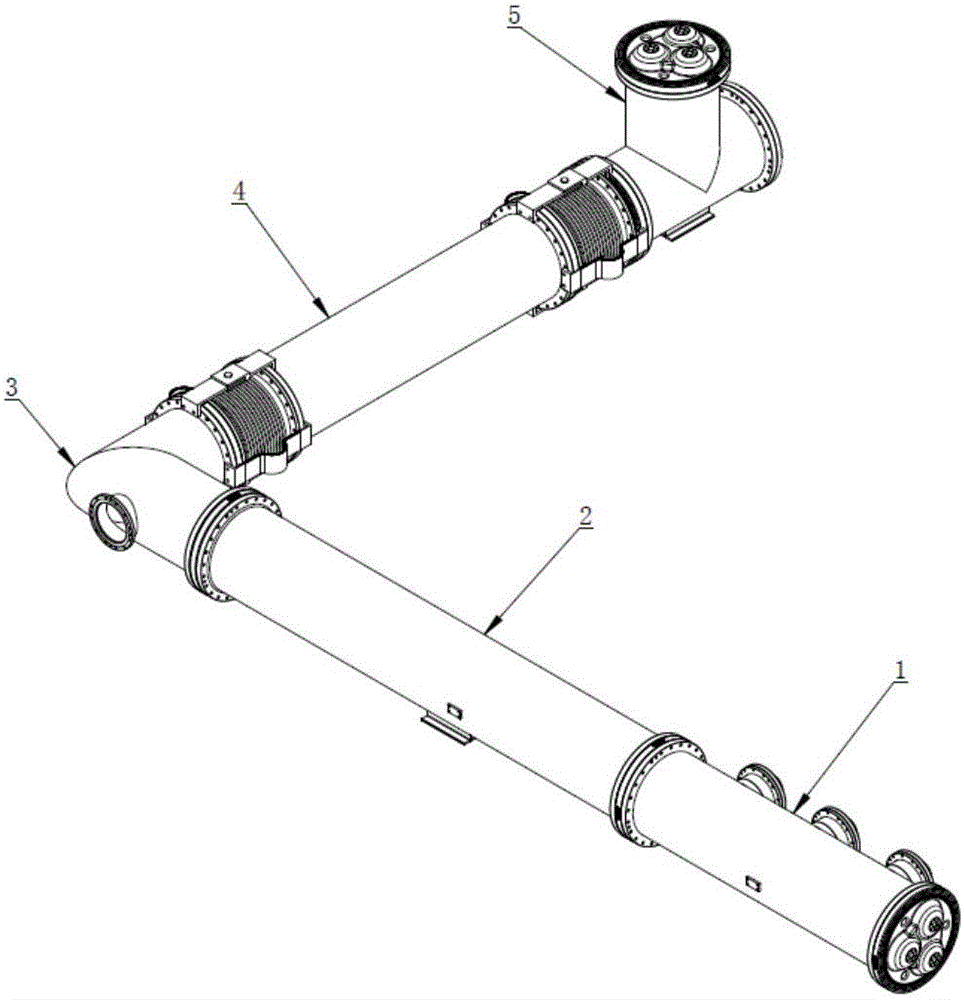

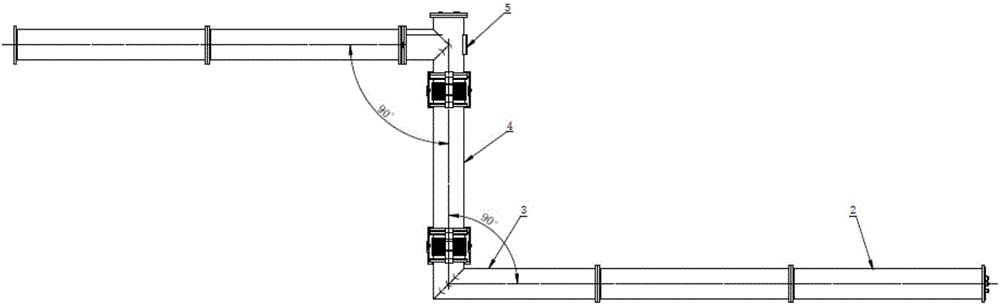

[0046] Such as figure 1 As shown, a three-phase communal rigid gas insulated transmission line includes a straight section unit 2 , a branch unit 1 , a corner unit 3 , a compensation unit 4 and a T-shaped unit 5 . The right port 55 of the T-shaped unit 5 is connected to one end of the compensation unit 4, the other end of the compensation unit 4 is connected to the short section housing 34 of the corner unit 3, the long section housing 35 is connected to one end of the straight section unit 2, and the straight section unit The other end of 2 is connected with branch unit 3. The interior of each unit shell is filled with insulating gas, the shells of each unit are connected by flanges, and the conductors in each unit are connected by plugging.

Embodiment 3

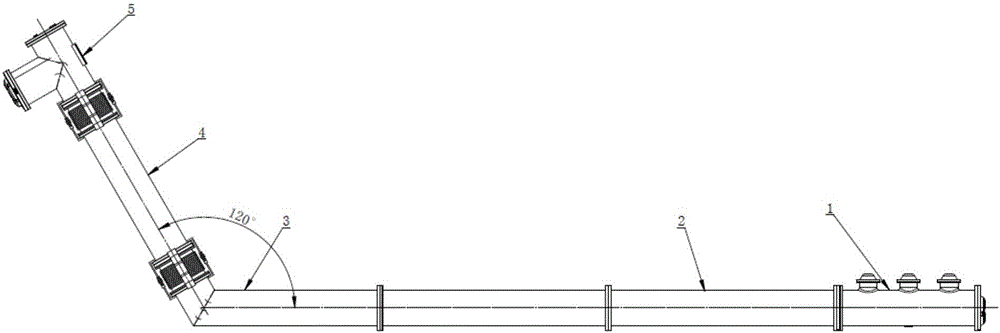

[0048] Such as figure 2 As shown, a three-phase communal rigid gas insulated transmission line includes two straight section units 2 , a corner unit 3 , a branch unit 1 , a compensation unit 4 and a T-shaped unit 5 . One end of the compensation unit 4 is connected to the left port 54, and the other end is connected to the short section housing 34 of the corner unit 3. The deflection angle of the corner unit is 120°, and of course it can be set to other angles as required. The long-section housing 35 of the corner unit 3 is connected to two straight-section units 2 in turn, and then connected to the branch unit 1 . Each unit is filled with insulating gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com