LED automobile lamp circuit board

A technology of LED car lights and circuit boards, applied in the field of LED lighting, can solve the problems of high junction temperature of LED chips, affecting LED luminous efficiency and service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

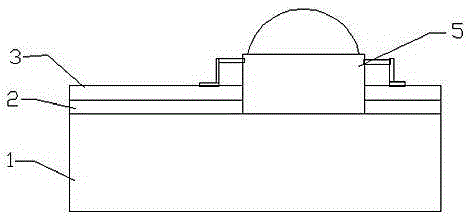

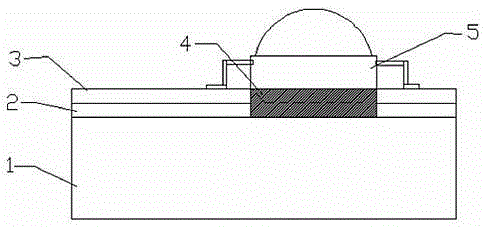

[0014] Such as figure 1 and figure 2 As shown, an LED lamp circuit board includes a heat dissipation metal substrate 1, an insulating layer 2 covering the heat dissipation substrate, a copper sheet 3 covering the insulating layer 2, and an LED chip 5 located above the copper sheet , wherein both the insulating layer 2 and the copper skin 3 are provided with holes exposing the heat dissipation metal substrate, and the bracket of the LED 5 is in direct contact with the heat dissipation metal substrate 1 through the holes of the insulation layer 2 and the copper skin 3 . On the surface of the exposed position of the heat dissipation substrate 1, that is, the surface corresponding to the holes of the insulating layer 2 and the copper skin 3, a heat conduction layer 4 is also provided. The heat conduction layer 4 can be plated with gold or silver, chromium, or zinc, or sprayed tin layer. The heat dissipation metal substrate 1 is made of copper plate, aluminum plate or other high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com