Solder alloy and package structure using same

A technology of solder alloy and structure, applied in the direction of welding/cutting media/materials, assembling printed circuits with electrical components, welding media, etc., can solve problems such as disconnection and solder joint cracks, and achieve sufficient reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

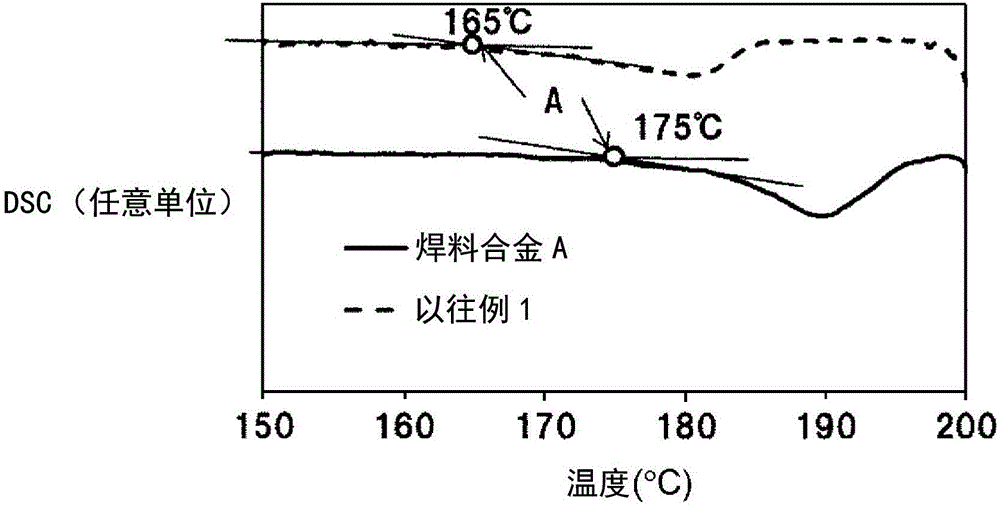

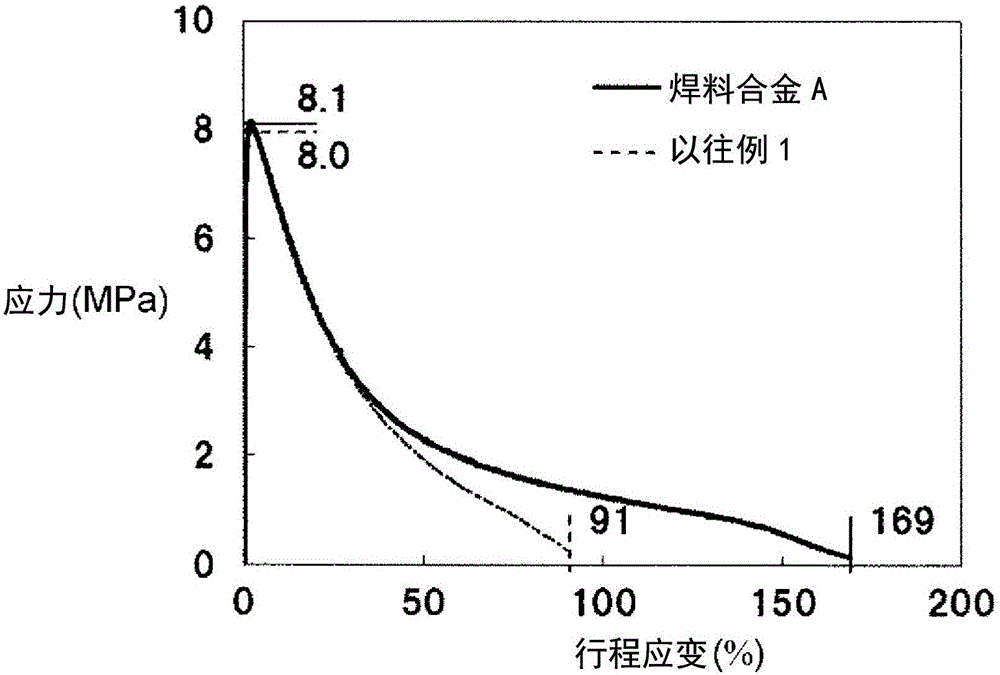

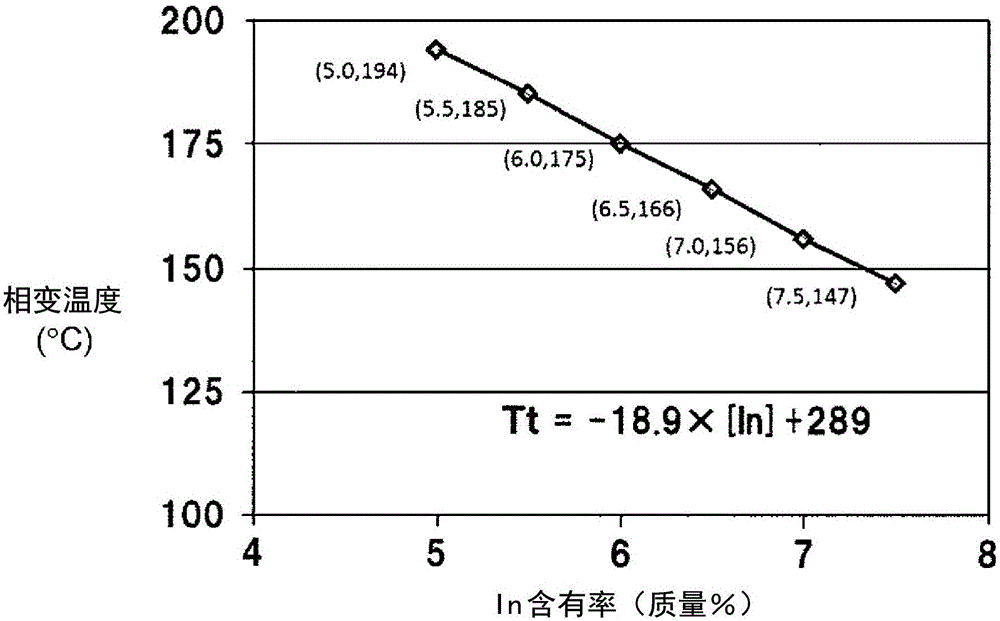

[0029] Before describing the embodiments of the present invention, problems in conventional solder alloys will be briefly described. The number of electronic devices mounted on automobiles is increasing day by day, but it is difficult to secure a mounting space for electronic devices in the limited space of automobiles. Therefore, the space is relatively enlarged by miniaturization of the electronic equipment, or the electronic equipment is installed in a place where the temperature becomes high and therefore the mounting is controlled conventionally from the viewpoint of reliability, such as an engine room. As a result of these, an increase in the heat generation density of electronic equipment due to miniaturization and an increase in ambient temperature occur, and the electronic equipment is exposed to higher temperatures. Furthermore, in order to cope with the evolution of future electronic equipment, it is necessary to exhibit high reliability, such as heat resistance, ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com