Hexagonal type barium titanate powder, producing method thereof, dielectric ceramic composition and electronic component

一种六方晶系、钛酸钡的技术,应用在钛化合物、钛酸酯、电气元件等方向,能够解决应用不充分等问题,达到充分可靠性、高相对介电常数、绝缘电阻优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0114] Hereinafter, the present invention will be described based on further detailed examples, but the present invention is not limited to these examples. In addition, in the following examples and comparative examples, "relative permittivity ε", "insulation resistance" and "Q value" were measured as follows.

[0115]

[0116] For capacitor samples, static electricity was measured at a reference temperature of 20°C using a digital LCR detector (YHP4274A manufactured by Yokogawa Electric Co., Ltd.) at a frequency of 1 MHz and an input signal level (measurement voltage) of 1 Vrms / μm. capacity C. The relative permittivity (unitless) was calculated from the obtained capacitance, the dielectric thickness of the multilayer ceramic capacitor, and the overlapping area between the internal electrodes.

[0117] Then, the insulation resistance IR after DC50V was applied to the capacitor sample at 25° C. for 60 seconds was measured using an insulation resistance meter (R8340A manufact...

experiment example 1

[0121]

[0122] First, as a raw material of barium titanate, BaCO 3 (specific surface area: 25m 2 / g) and TiO 2 (specific surface area: 50m 2 / g). In addition, as a raw material of Mn, Mn 3 o 4 (specific surface area: 20m 2 / g), as the raw material of element M, La(OH) was prepared 3 (specific surface area: 10m 2 / g).

[0123] Weigh these raw materials, so that the general formula (Ba 1-α m α ) A (Ti 1-β mn β ) B o 3 α, β, and A / B in are the values shown in Table 1, respectively, and water and a dispersant were mixed together using a ball mill. The obtained mixed powder was treated under the following heat treatment conditions to produce hexagonal barium titanate powder.

[0124] The heat treatment conditions are: the heating rate is 200°C / hour, the holding temperature is the temperature shown in Table 1, the temperature holding time is 2 hours, the cooling rate is 200°C / hour, and the atmosphere gas is air.

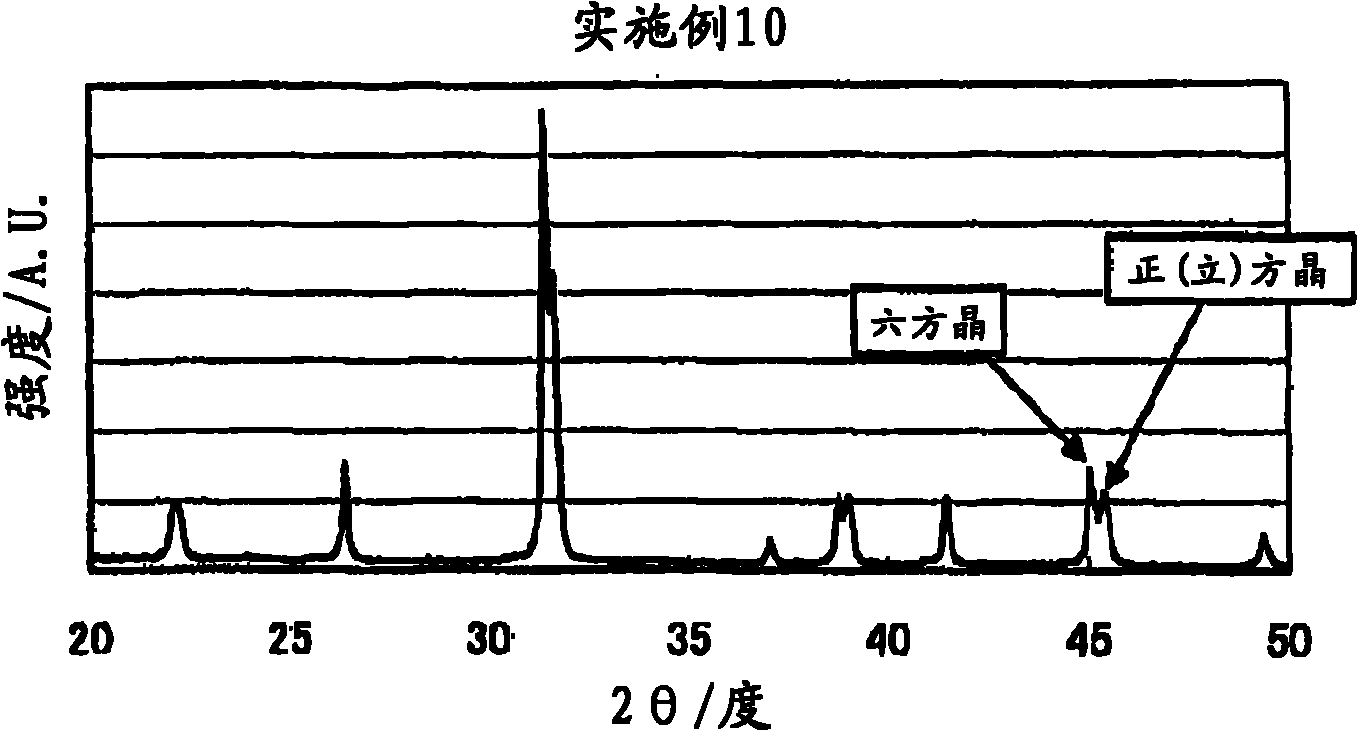

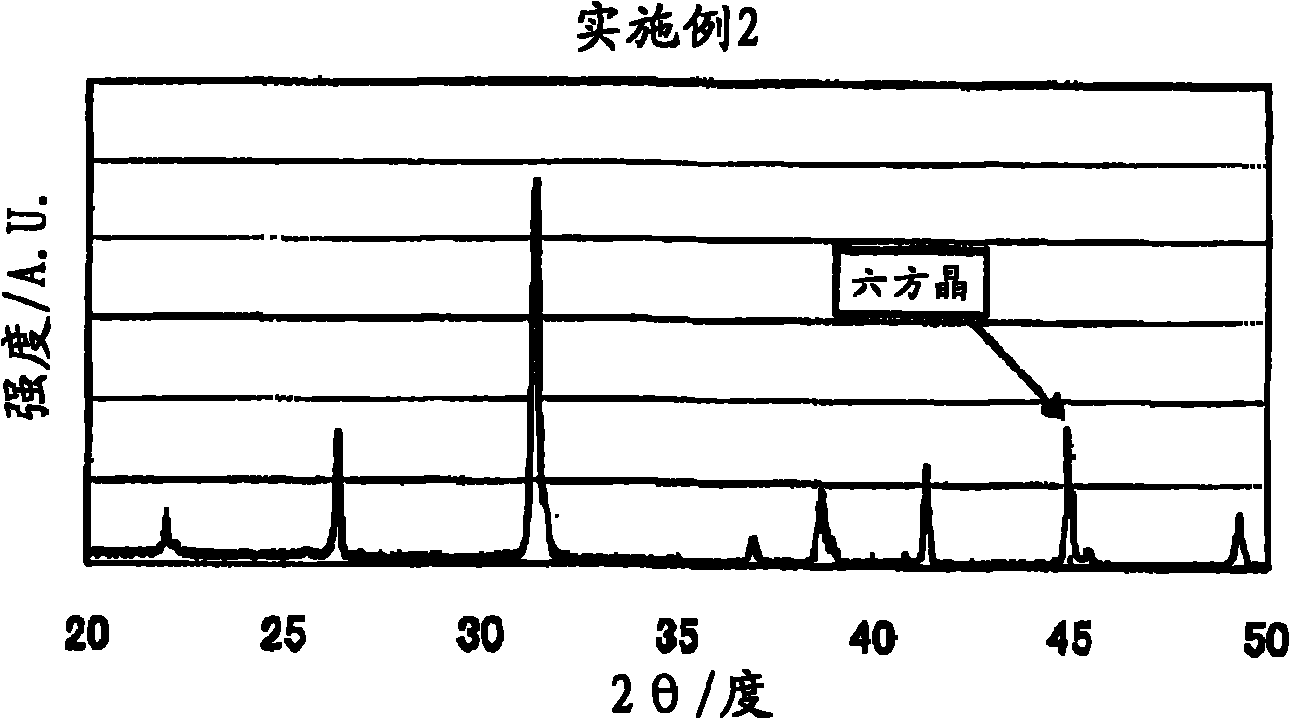

[0125] The obtained hexagonal barium titanate p...

experiment example 2

[0142] In addition to using the oxides, carbonates, and hydroxides of the elements shown in Table 4 instead of La(OH) 3 A powder was produced in the same manner as in Example 2 except that the raw material of the element M was used, and the specific surface area and X-ray diffraction were measured. The results are shown in Tables 4-6.

[0143]

[0144]

[0145]

[0146] From Tables 4 to 6, it was confirmed that even when an element other than La was used as the element M, there was a tendency similar to that of Example 2.

[0147] From the above, it can be confirmed that the hexagonal barium titanate powder of the present invention contains hexagonal barium titanate as a main component and has a specific surface area of 2 m 2 / g or more, the particle size distribution is narrow.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com