Scale on device for measuring displacement

A scale and displacement technology, applied in measuring devices, electrical devices, mechanical devices, etc., can solve the problems of corrosion, coolant and oil ingress, measurement errors, etc., and achieve the effect of full reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

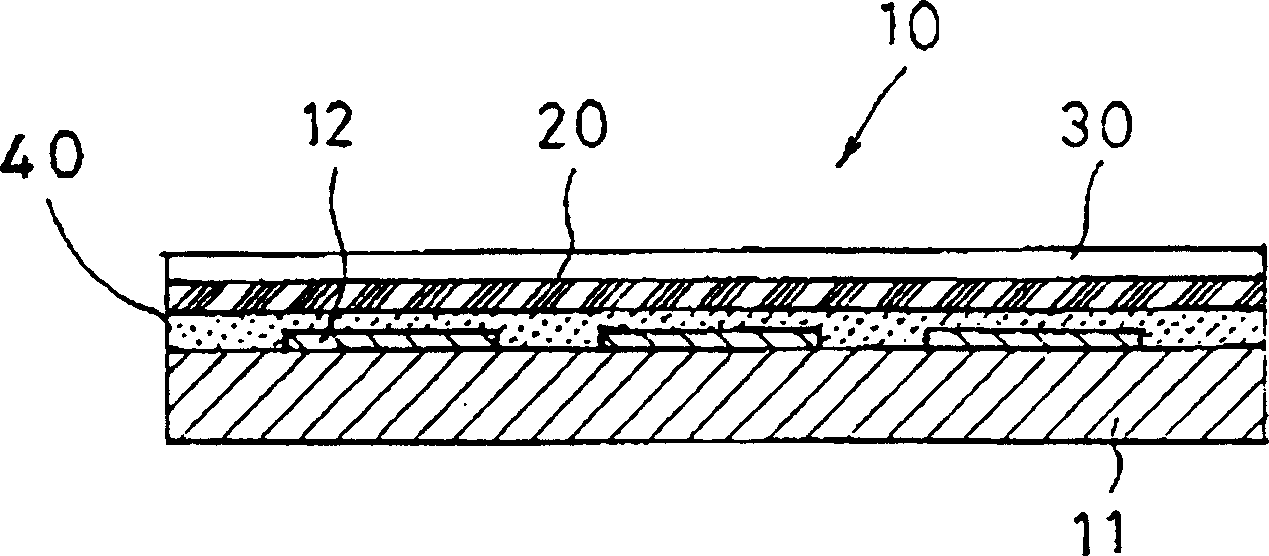

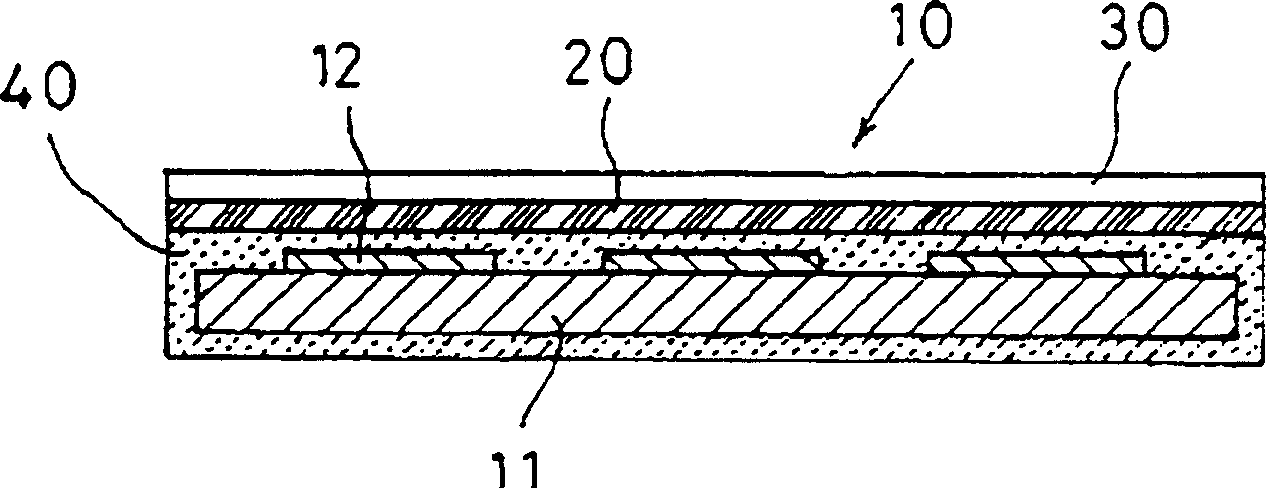

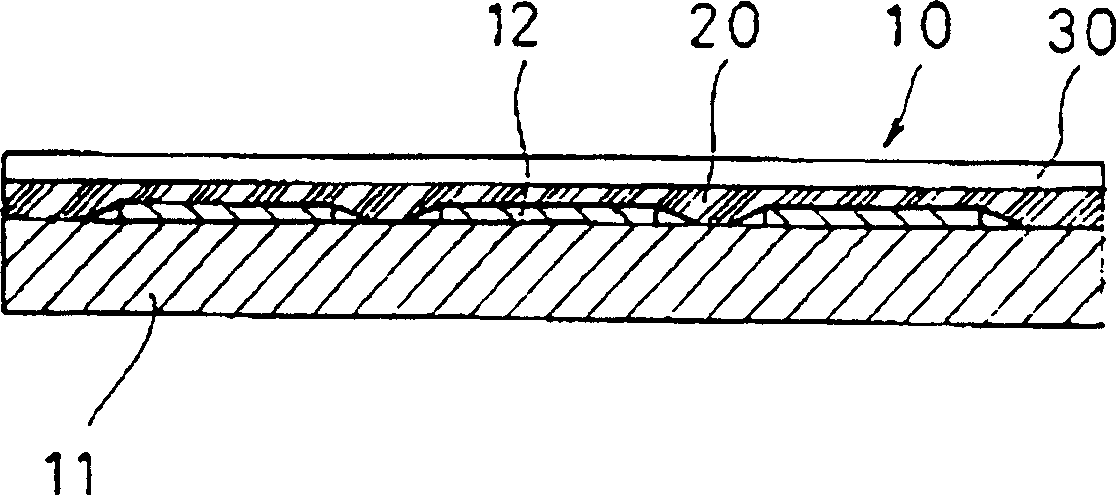

[0017] Referring to the accompanying drawings, preferred embodiments of the present invention will be described below. figure 1 is a cross-sectional view of the scale on the displacement measuring device of the first embodiment. The scale includes a scale part 10 that contains a plurality of rectangular wire grids distributed at intervals on a glass-epoxy resin substrate 11, etc., and one side of the scale part 10 that is formed with a plurality of rectangular wire grids 12 is covered. A coating 40 on the top, a scale cover (film layer) 30 used as a protective layer, and a scale constituting material adhered to the outside of the coating 40 by an adhesive layer 20 so as to prevent pollutants or oil from entering the rectangular wire grid 12 and between adhesive layers 20 such as adhesive tape.

[0018] The scale includes a coating 40 that is cleaned, activated, and roughened by plasma radiation after coating the coating 40 on the side of the scale where the rectangular wire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com