Hydraulically-driven rape combine harvester

A combine harvester and rapeseed technology, applied to harvesters, agricultural machinery and implements, threshing equipment, etc., can solve problems such as complex transmission, complex structure, and large vibration of the whole machine, and achieve simple overall structure, simple operation, and reduced overall cost. The effect of machine vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

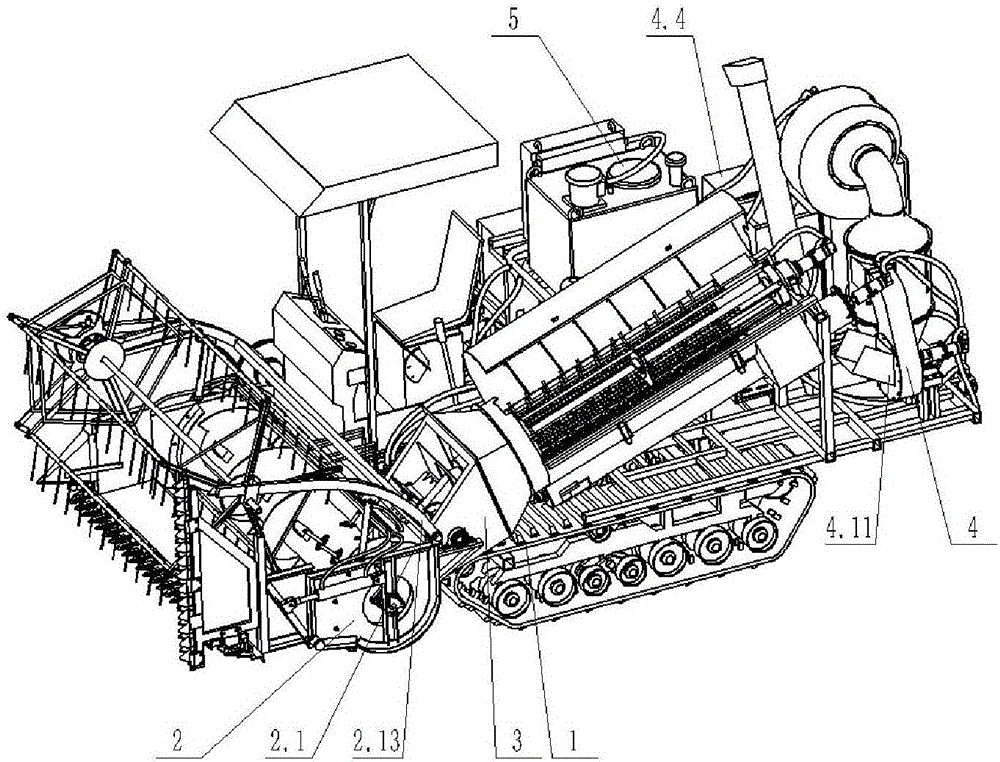

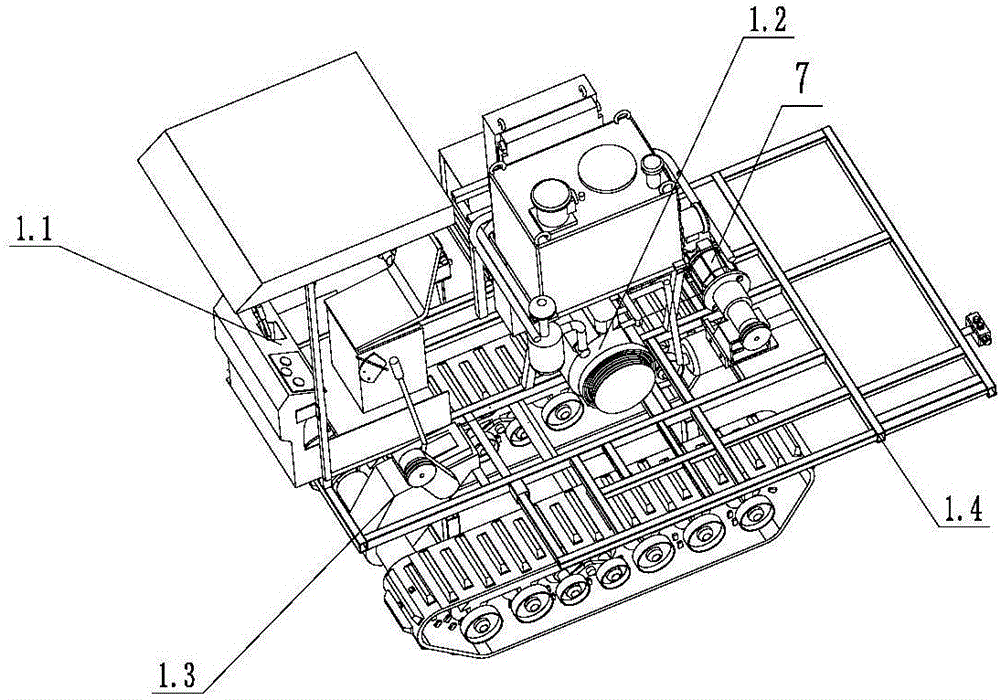

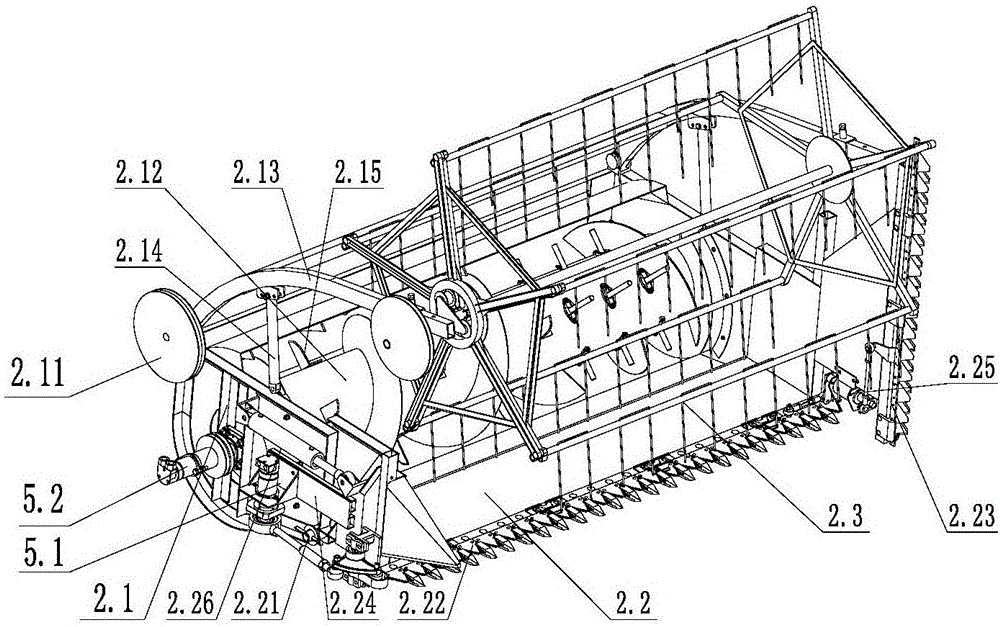

[0026] Such as figure 1 As shown, the hydraulically driven rapeseed combine harvester of the present invention includes a crawler-type chassis running device 1, a header 2 arranged at the front end of the crawler-type chassis running device 1, and a forced-feeding belt connected to the outlet of the header 2 rear end. The vertical axial flow threshing separation device 3 of the device and the cyclone separation and cleaning system 4 arranged at the rear end of the crawler chassis walking device 1, wherein: the longitudinal axial flow threshing separation device with a forced feeding device is a Chinese invention patent application (publication number 106105581A , Publication date 2016-11-16) discloses a longitudinal axial flow threshing and separation device with a forced feeding device, which replaces the traditional chain rake conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com