A processing method for cut stems with low crotonaldehyde emission and its products and applications

A treatment method and technology of release amount, applied in the field of tobacco processing, can solve the problems of cumbersome treatment process, unfavorable use, etc., and achieve the effects of convenient operation, reduced release amount, and increased Maillard reaction products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

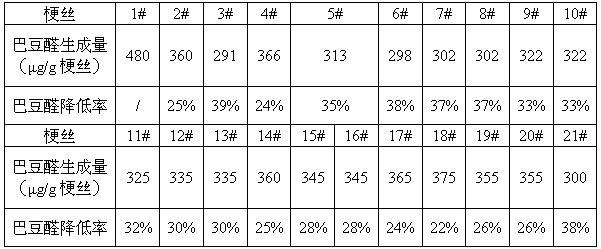

Embodiment 1

[0025] Example 1 (compared with shredded stem 1 #)

[0026] Tobacco stems are made into shredded stems by conventional methods in the art, and used as a contrast, specifically through the following processing steps:

[0027] 1) Stem washing: Tobacco stems are washed to remove floating dust, and the moisture content is adjusted to about 40% for pressing and shredding;

[0028] 2) Stem pressing and shredding: the wet tobacco stems are pressed using a stem pressing machine, and shredded by a shredding machine with a width of 1.2mm;

[0029] 3) Drying: the control shredded stems were obtained by drying with a silk dryer.

Embodiment 2

[0030] Example 2 (stem 2 #)

[0031] A method for processing shredded stems with low crotonaldehyde emission, using tobacco stems as raw materials, comprising the following steps:

[0032] 1) Water extraction: extract the tobacco stems with water at 25°C for 12 hours, and use a screen to separate the solids and liquids to obtain the extract and residual stems; the amount of water used is 10 times the weight of the tobacco stems;

[0033] 2) Fermentation of the extract: After the extract is concentrated to 1 / 10 of the original volume, add active dry yeast (Saccharomyces cerevisiae) and ferment at 40°C for 0.5h; the amount of yeast used is 0.5% of the weight of the tobacco stems,

[0034] 3) Squeeze and shred the remaining stalks: adjust the water content of the remaining stalks to about 40%, use a stalk press to press the remaining stalks into slices, and use a shredder to cut the stalks into shreds;

[0035] 4) Feed liquid back-adding: add back the fermented extract obtained ...

Embodiment 3

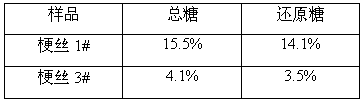

[0037] Example 3 (stem shredded 3 #)

[0038] A method for processing shredded stems with low crotonaldehyde emission, using tobacco stems as raw materials, comprising the following steps:

[0039] 1) Water extraction: extract the tobacco stems with water at 25°C for 12 hours, and use a screen to separate the solids and liquids to obtain the extract and residual stems; the amount of water used is 10 times the weight of the tobacco stems;

[0040] 2) Fermentation of the extract: After the extract is concentrated to 1 / 10 of the original volume, add active dry yeast (Saccharomyces cerevisiae) and ferment at 40°C for 0.5h; the amount of yeast used is 0.5% of the weight of the tobacco stems,

[0041] 3) Squeeze and shred the remaining stalks: adjust the water content of the remaining stalks to about 40%, use a stalk press to press the remaining stalks into slices, and use a shredder to cut the stalks into shreds;

[0042] 4) Adding amino acids to the extract and adding back: addin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com