Silicone gel dressing and production process thereof

A technology of silicone gel and production technology, applied in medical science, bandages, etc., can solve problems such as scars, secondary injuries, and aesthetic impact, and achieve the effects of small usage, environmental protection, and resource conservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

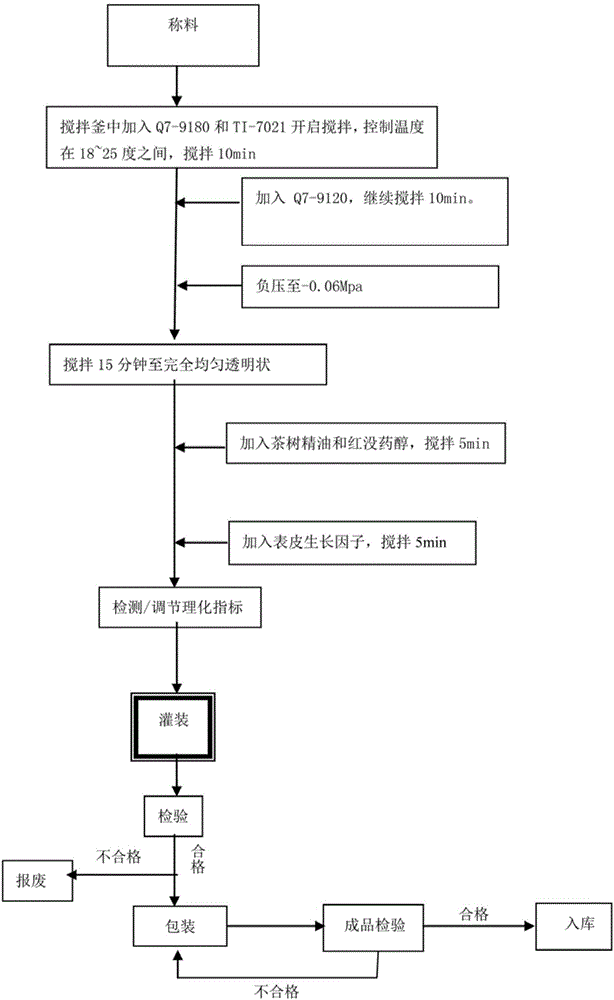

Method used

Image

Examples

Embodiment 1

[0027] A kind of silicone gel dressing provided by the invention, its formula comprises the silicone oil Q7-9120 that the viscosity is 58.9% of the viscosity of 100cst, the silicone oil mixture T1-7021 that the viscosity is 0.1% of the viscosity is 12500cst, and the viscosity is 0.65% by weight. 40% polydimethylsiloxane Q7-9180 of cst, 3% tea tree essential oil and 1% bisabolol, which need to add 0.1mg / KG epidermal growth factor in production.

Embodiment 2

[0029] A kind of silicone gel dressing provided by the invention, its formula comprises the silicone oil Q7-9120 of 80% with the viscosity of 100cst, the silicone oil mixture T1-7021 of 0.5% with the viscosity of 12500cst, and the viscosity of 0.65% by weight. 19% polydimethylsiloxane Q7-9180 of cst, 0.3% tea tree essential oil and 0.2% bisabolol, which need to add 0.2mg / KG epidermal growth factor in production.

Embodiment 3

[0031] A kind of silicone gel dressing provided by the present invention, its formula comprises the silicone oil Q7-9120 of 40% with the viscosity of 100cst, the silicone oil mixture T1-7021 of 20% with the viscosity of 12500cst, and the viscosity of 0.65% by weight. 36% polydimethylsiloxane Q7-9180 of cst, 3% tea tree essential oil and 1% bisabolol, which need to add 0.5mg / KG epidermal growth factor in production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com