Winding fixing method for preventing fold deformation of filter element, filter element and filter

A fixing method and filter element technology, applied in separation methods, cartridge filters, chemical instruments and methods, etc., can solve the problems of filter paper or filter material being folded or deformed, short life, affecting the effective use of filter area and the service life of the filter element. , to achieve the effect of avoiding and folding deformation and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

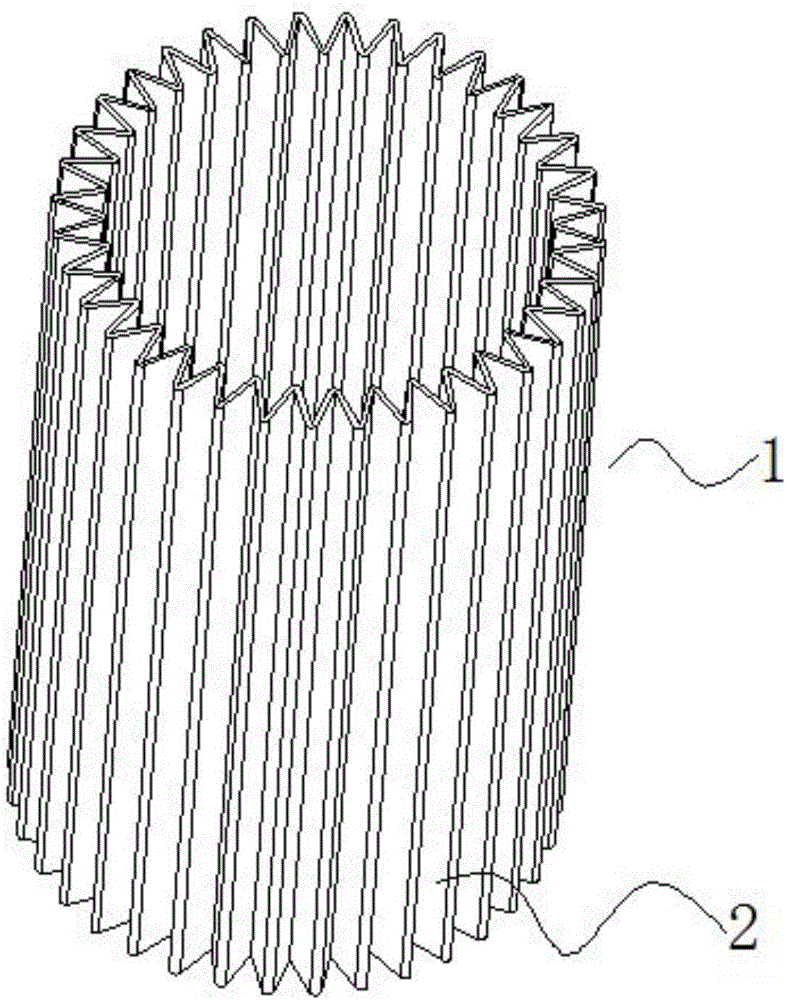

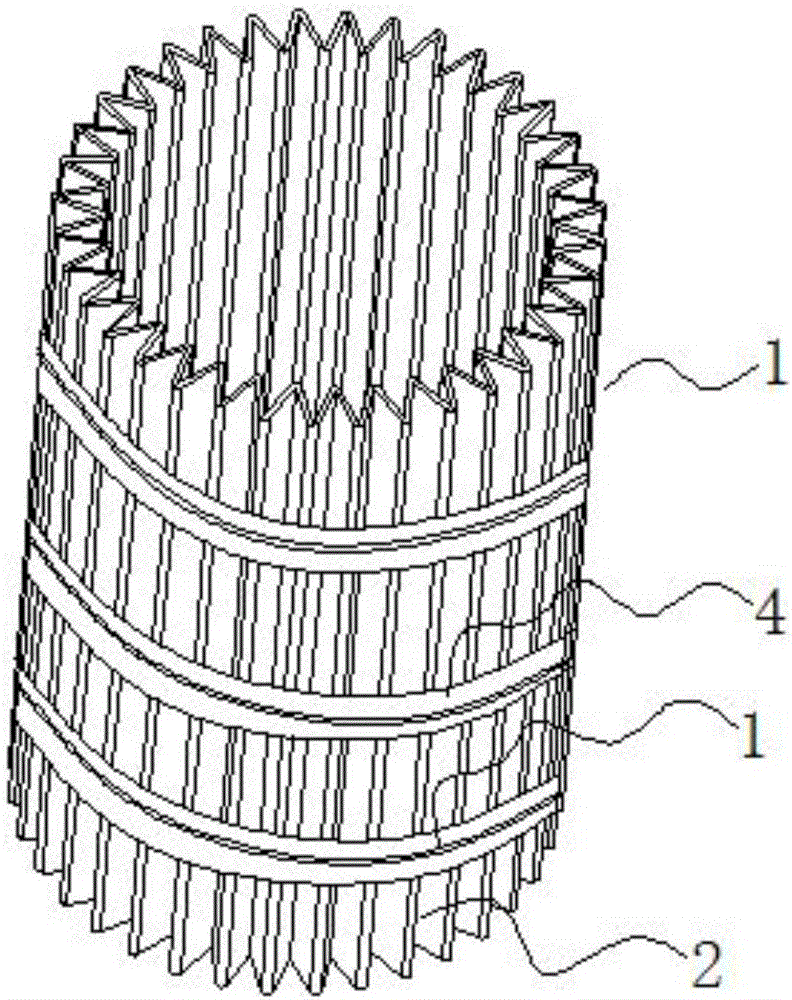

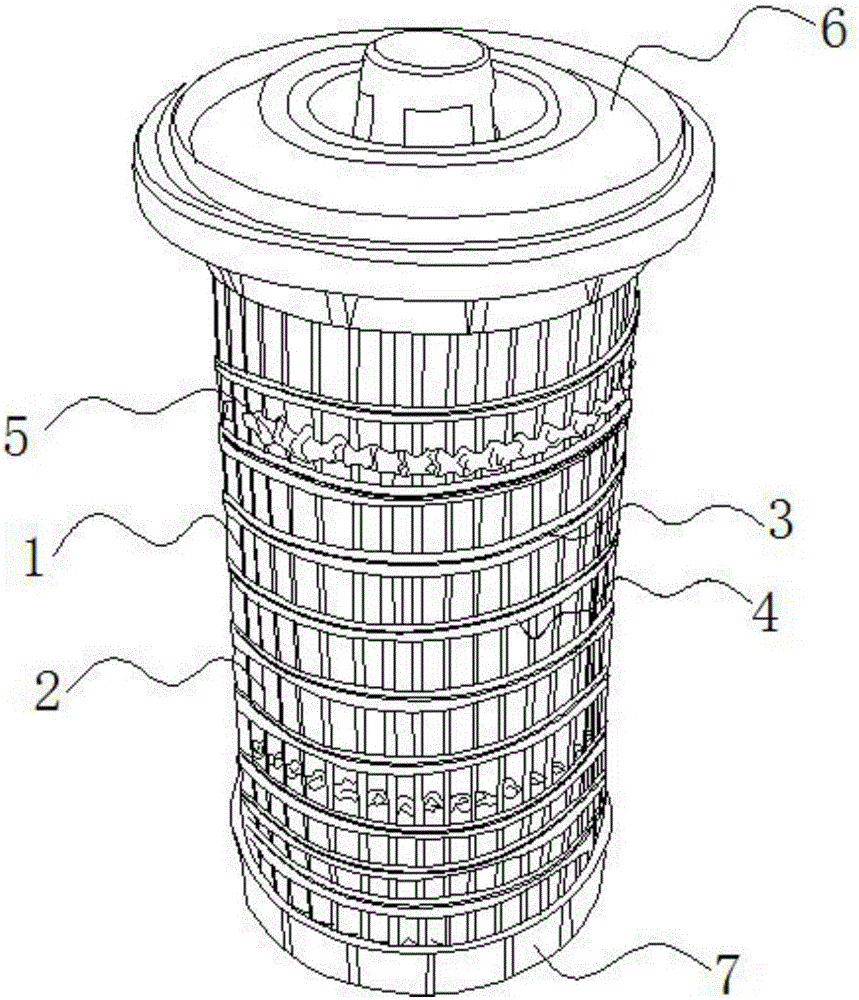

[0022] see Figures 1 to 4 , the winding fixing method provided in this embodiment to prevent the filter element from collapsing and deforming includes the following steps:

[0023] 1) Choose a folded cylindrical filter element 1, which includes a number of continuous folded parts 2, and these folded parts 2 are connected to each other to form a cylindrical structure; choose glass fiber or cotton thread, glass fiber 3 is used in this embodiment, The fiber is 1200 strands of glass fiber; the glue is selected, and the glue taste is EVA hot melt adhesive with high and low temperature resistance and oil resistance, or two-component epoxy resin AB adhesive glue;

[0024] 2) The glass fiber 3 is spirally wound on the outer surface of the folded cartridge filter element 1, and while the glass fiber 3 is spirally wound, the wound glass fiber 3 is glued; after the glue is dry (forming the glue layer 4), The glue layer 4 bonds and fixes the glass fiber 3 and the filter paper together. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com