Gas-liquid distributor

A gas-liquid distributor and downcomer technology, which is applied in fluid mixers, chemical instruments and methods, mixers, etc., can solve problems such as uneven temperature distribution of the catalyst bed, lower catalyst utilization rate, and lower product quality. Achieve the effects of wide application range, large operating flexibility, and large liquid phase spraying area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

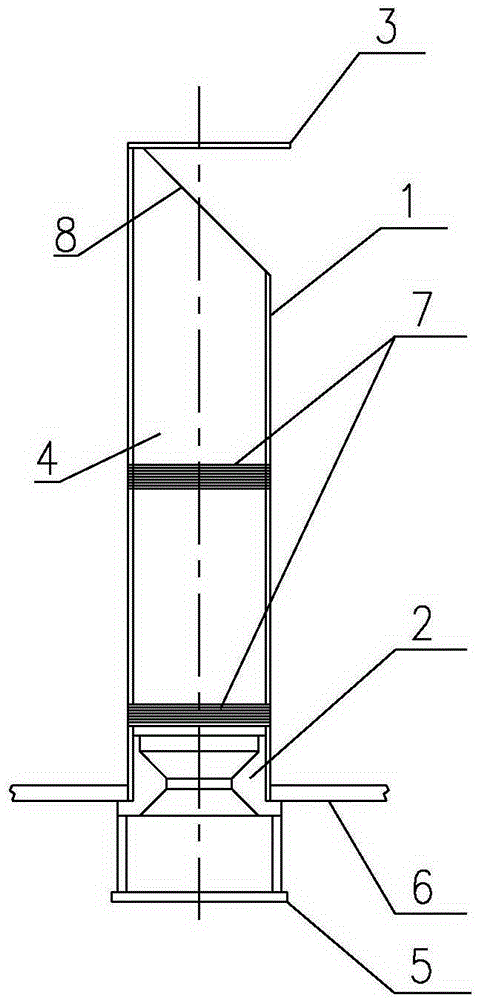

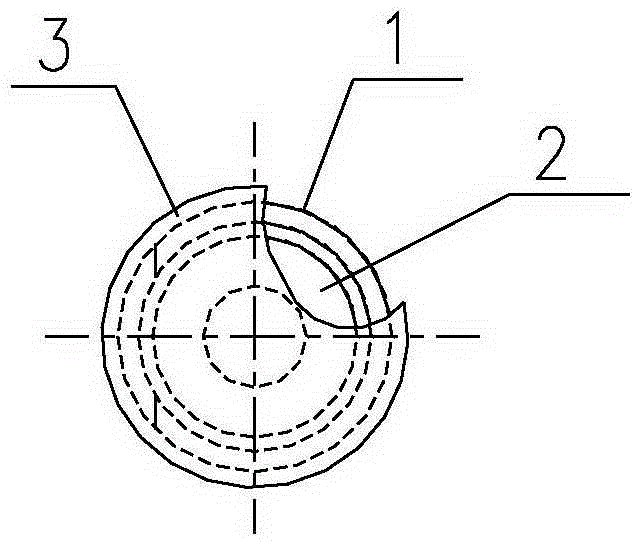

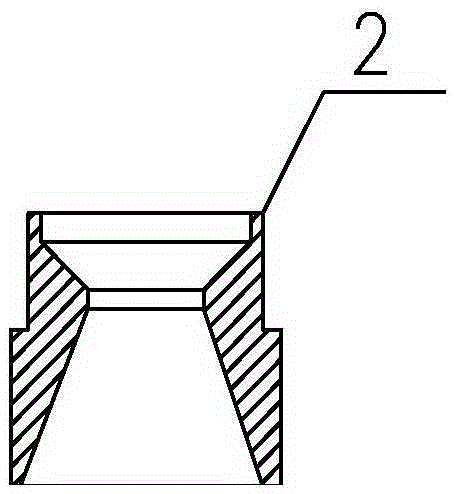

[0017] see figure 1 , a gas-liquid distributor of the present invention, which includes a cover plate 3 and a central pipe 1, the central pipe 1 is vertically arranged, the cover plate 3 is horizontally arranged above the central pipe 1, and the central pipe 1 includes an inlet portion and a downcomer portion 4 , the downcomer 4 is below the inlet, the lower end of the central tube 1 is the central tube outlet, the top of the central tube 1 is beveled, and the beveled cut 8 formed by the beveled top of the central tube 1 and the space formed by the cover plate 3 There are several rows of metal strip screens (Johnson nets) distributed along the axial direction of the central pipe 1 on the downcomer 4 , and a jet mixing device 2 is arranged below the outlet of the central pipe 1 .

[0018] A gas-liquid distributor of the present invention can also include a broken flow plate 5, the broken flow plate 5 is horizontally arranged below the jet mixing device 2, and the broken flow pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com