Broken-belt reduction control method for cold rolling production of 5182 aluminum alloys

A control method and aluminum alloy technology, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve problems such as intensified work hardening, large tensile stress at both sides of the material, and increased tendency of edge cracking, etc., to achieve reduction The effect of strip breakage in cold rolling mill, stable product quality, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the drawings and embodiments.

[0038] This embodiment provides a method for reducing strip breakage in cold rolling production of 5182 aluminum alloy, which specifically includes the following steps:

[0039] Step S1: Establish the edge coverage weight of 5182 alloy strip according to the following formula:

[0040] F d =[(W (x) *F e ) / X e ]+[1-W (x) *F e±1 ] / X e±1 ;

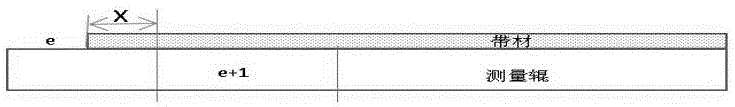

[0041] Where X e Covering width of the strip edge in the plate-shaped roll area, W (x) Is the weight of the strip edge coverage area, F e Is the force of the edge area of the shape meter, e±1 is the number of adjacent areas on both sides of the strip. The specific calculation principle diagram is as follows figure 1 Shown

[0042] Step S2: Fit the flat target curve:

[0043] Y=-5x 2 -130x 6 +110x 8 ;

[0044] Among them, x is the width specification of the strip, the center position of the strip is zero, the width of the strip ranges from -...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com