Novel filler of extrusion tee joint and machining technology of novel filler

A processing technology and filler technology, applied in the field of tee pipe fittings, can solve problems such as cumbersome production steps, achieve the effects of improving processing accuracy and production efficiency, high manufacturing efficiency, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

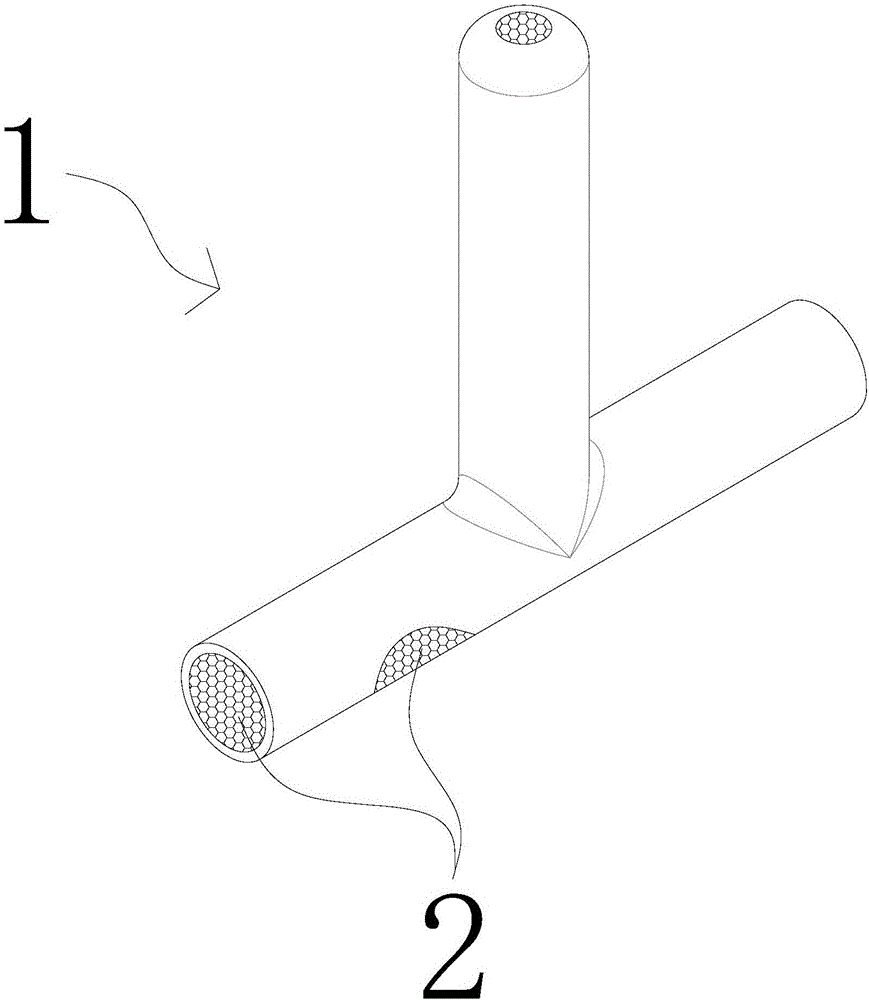

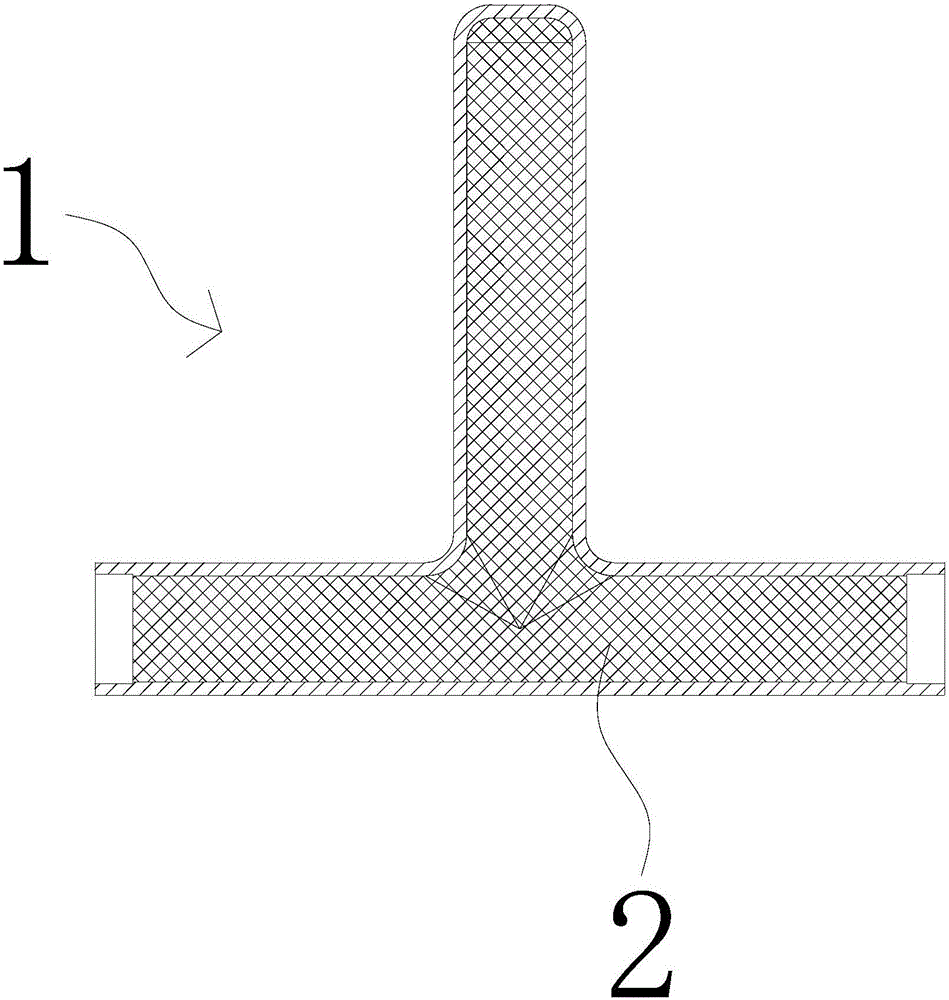

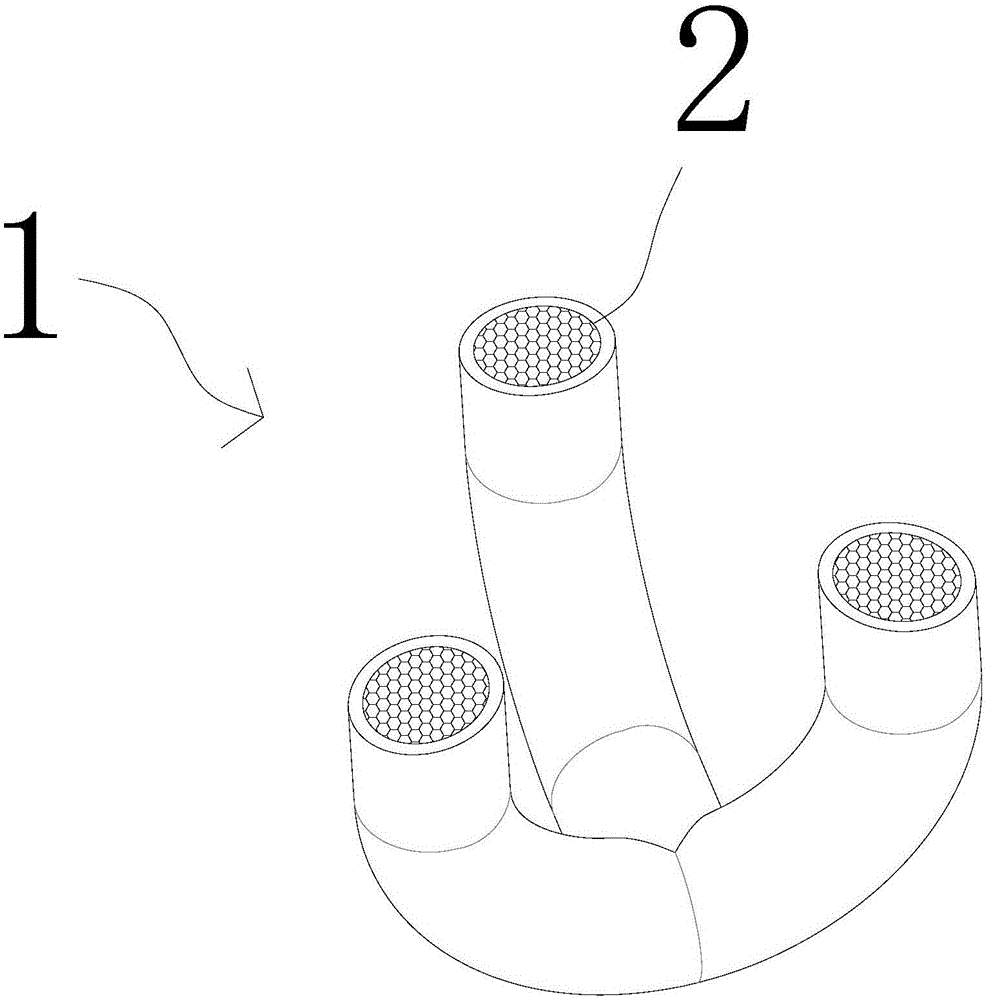

[0046] 55% of magnesium silicate, 15.9% of aluminum silicate, 15.4% of barium silicate, 1.1% of calcium silicate and 12.6% of alkane compound prepared in percentage to prepare a paste-like mixed paste 2 or liquid To be filled and used: the first step, material cutting: put the metal pipe into the self-developed straight tube cutting machine for material cutting, and set the cutting length, after cutting the material, transfer to the next process of filling; second Step 1, filling: adjust the temperature in the melter to an appropriate temperature, put the prepared mixed paste 2 into the melter of the filling machine, make it melt into a gel, and then cut the material in the first step The metal pipes are loaded into the automatic feeding tray of the filling machine for automatic filling. The third step, extrusion: Put the metal pipe filled in the second step into the mold of the hydraulic press, press the start button to extrude, extrude into a T-shaped tee piece 1, and then d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com