Following welding fixture for welding guns and sensors

A welding fixture and sensor technology, applied in the field of welding fixtures, can solve problems such as the inability to accurately observe the position of the weld, the inability to achieve stability and consistency, and welding deviation, so as to improve the quality of welding processing and reduce the use of materials and quality , The effect of reducing the cost of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

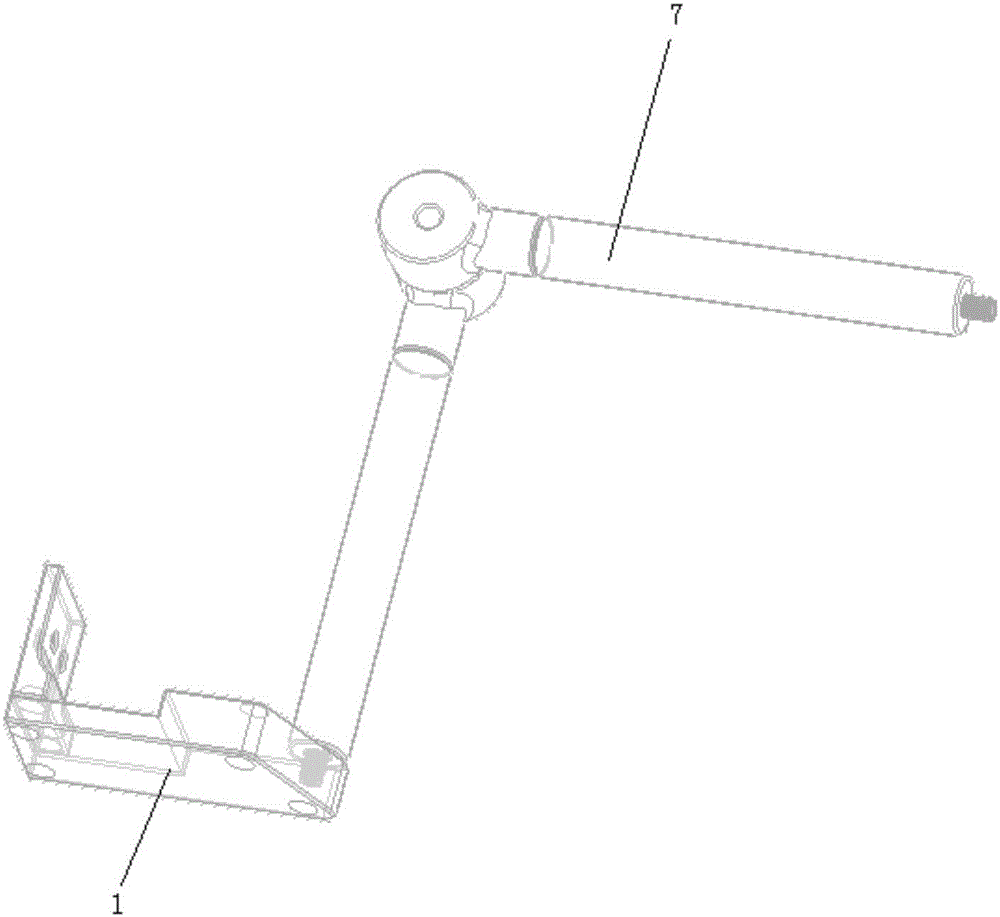

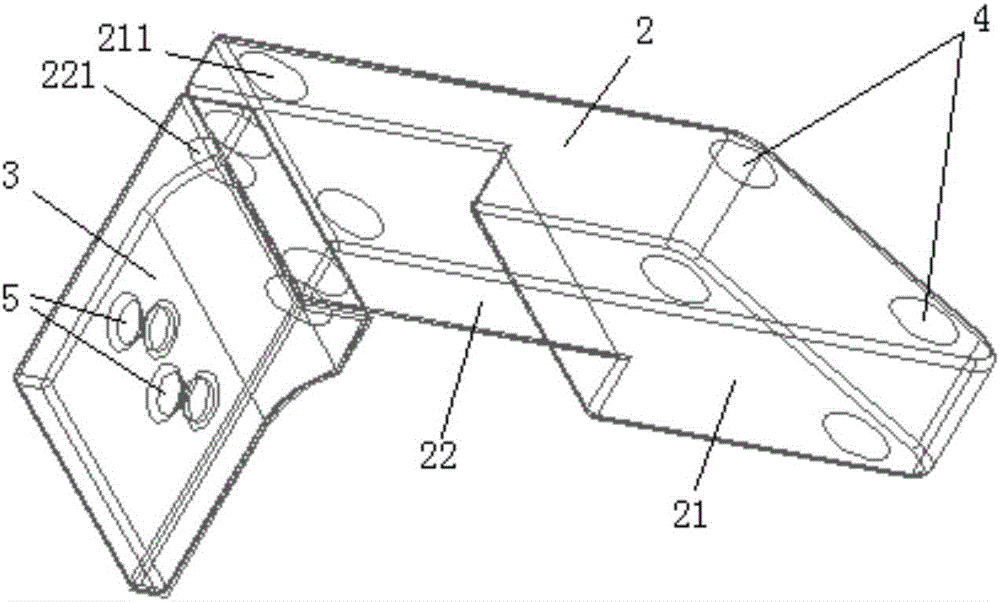

[0022] Such as Figure 1-3 As shown, the present invention provides an accompanying welding fixture for welding robots and sensors, which specifically includes the following components:

[0023] An L-shaped base 1 composed of a fixed plate 2 and a side plate 3 arranged on the side of the fixed plate 2, the central symmetry line on the fixed plate 2 coincides with the center line of the right-angle waist of the side plate 3;

[0024] Two sensor screw holes 5 arranged symmetrically on the side plate 3, located on both sides of the center line of the side plate 3;

[0025] It is arranged on the top of the fixed plate 2 and is provided with two connecting screw holes 4 for connecting the connecting frame 7 respectively;

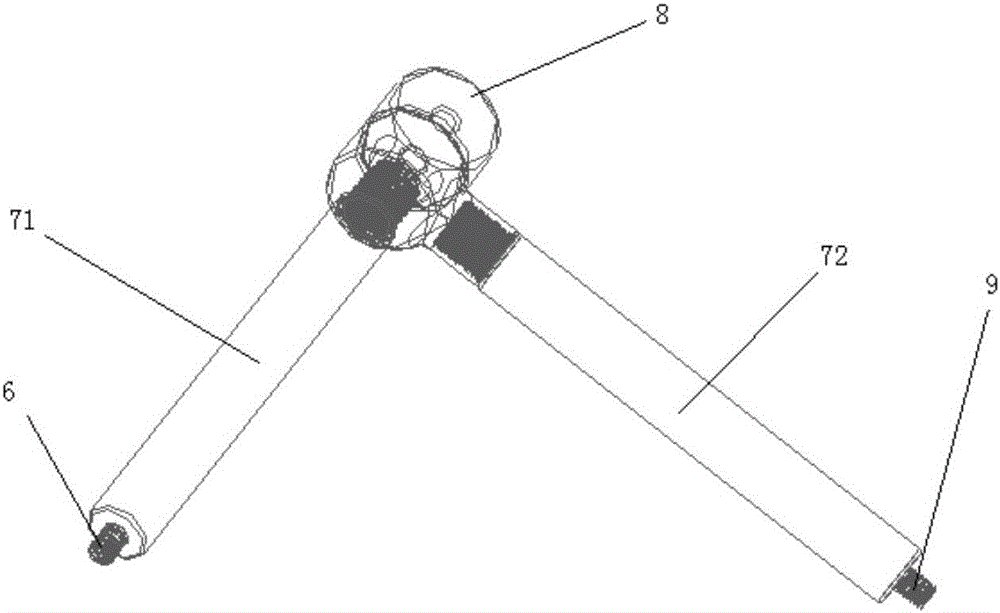

[0026] A freely movable hinge 8 is provided on the connecting frame 7;

[0027] Set on the connecting frame 7, there are first bolts 6 and second bolts 9 at both ends of the connecting bracket 7, and the first connecting rod is connected with any one of the connecting scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com