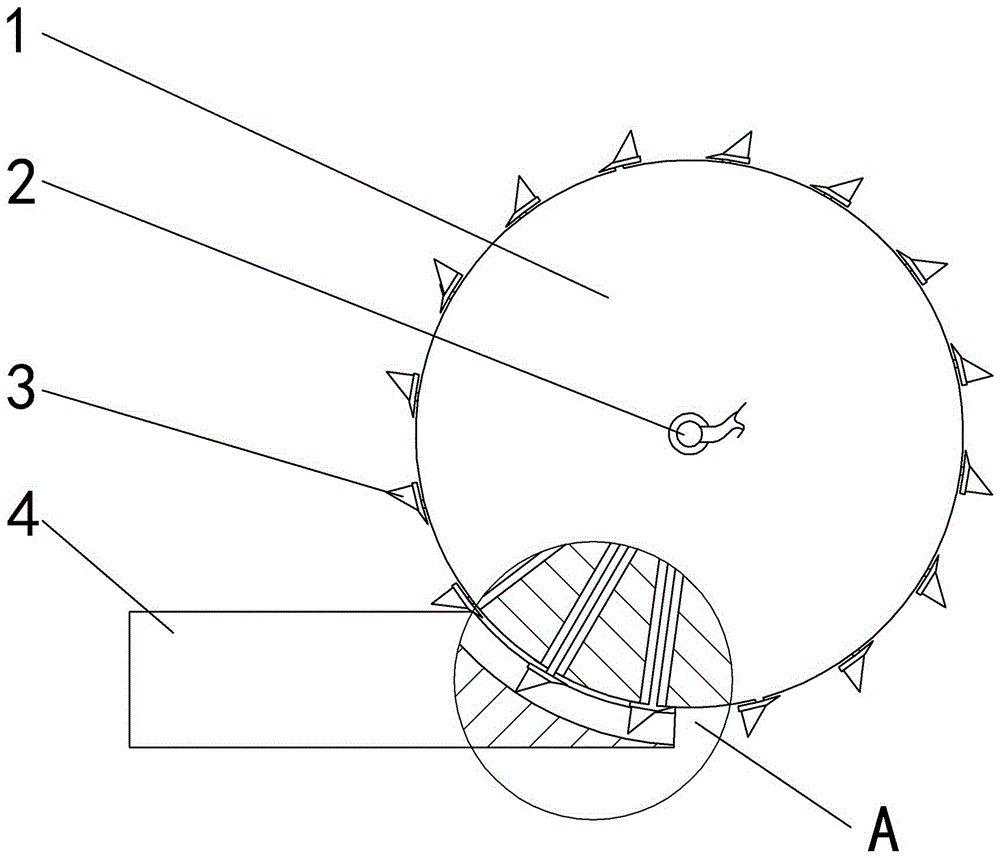

Circular saw used for cutting door plank

A circular saw and door panel technology, which is applied to circular saws, saw blades, sawing equipment, etc., can solve the problems of heat dissipation difficulties of saw blades, and achieve the effect of solving heat dissipation difficulties and saving wood.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

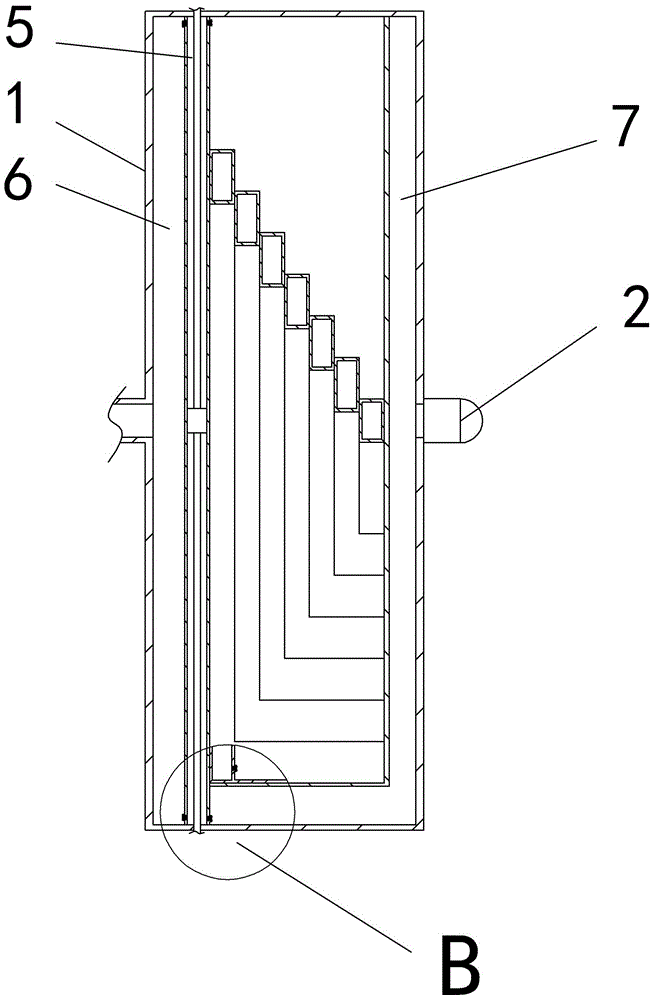

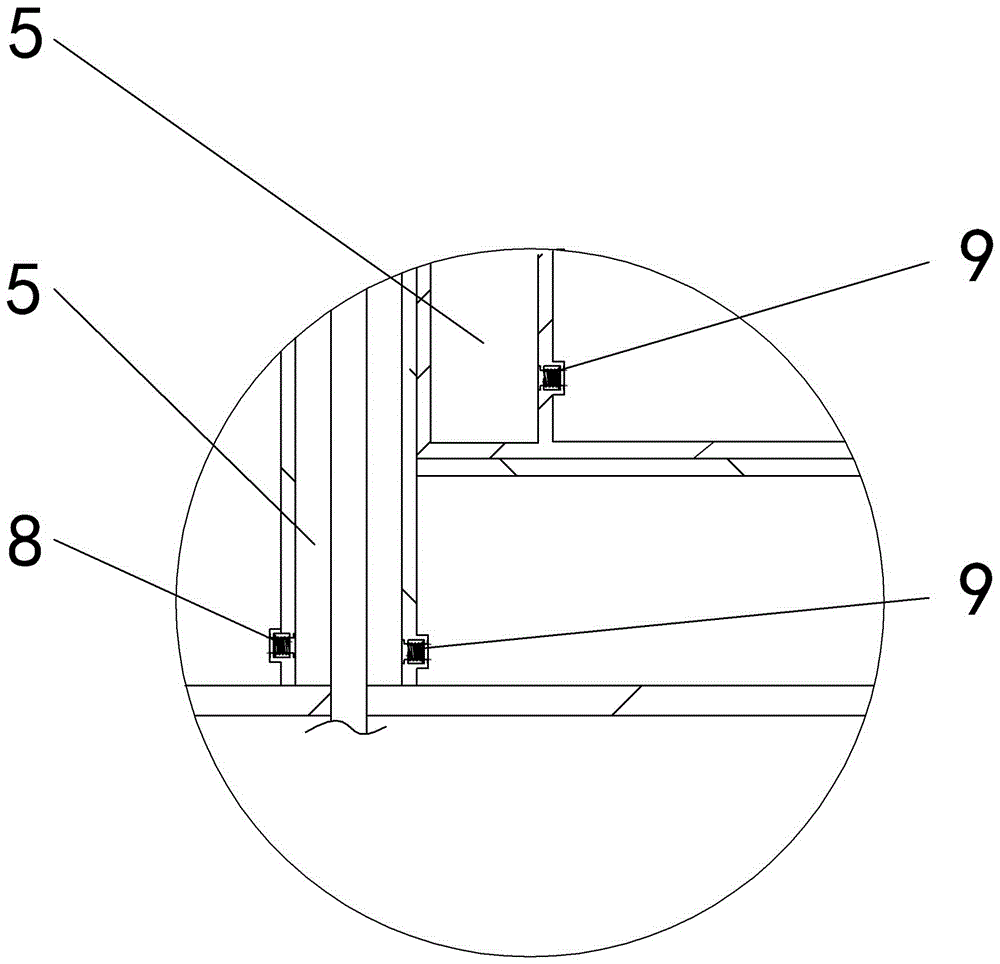

[0019] Embodiment: The circular saw used for cutting door panels in this solution includes a motor, a disc 1 and several sawtooth units, the center of the disc 1 is connected to the output end of the motor, and the disc 1 is integrally formed with a first cavity 7 and The second cavity 6, the first cavity 7 and the second cavity 6 are located on both sides of the disk 1 respectively, the output end of the motor is hollow, the output end of the motor communicates with the second cavity 6, and the output shaft of the motor is connected with Refill pump. The sawtooth unit includes a hydraulic cylinder 5, a first piston rod 10, a second piston rod 10 and a piston. The hydraulic cylinder 5 is plate-shaped. The hydraulic cylinders 5 are arranged along the diameter of the disc 1. Each hydraulic cylinder 5 is arranged overlappingly. Two overflow valves 9 and two one-way valves 8 connecting the second cavity 6 to the hydraulic cylinder 5 are installed on the cylinder body 5. The two ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com