3D printing capacitive intelligent skin and preparation method thereof

A smart skin and 3D printing technology, applied in manufacturing, additive processing, etc., can solve problems such as unfavorable large-scale production applications, difficulty in processing precise microstructures, complex hydrogel assembly structures, etc., and achieve broad industrial application prospects , strong universality, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

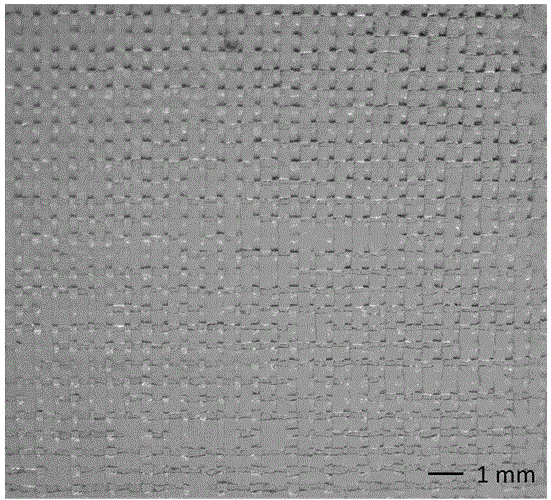

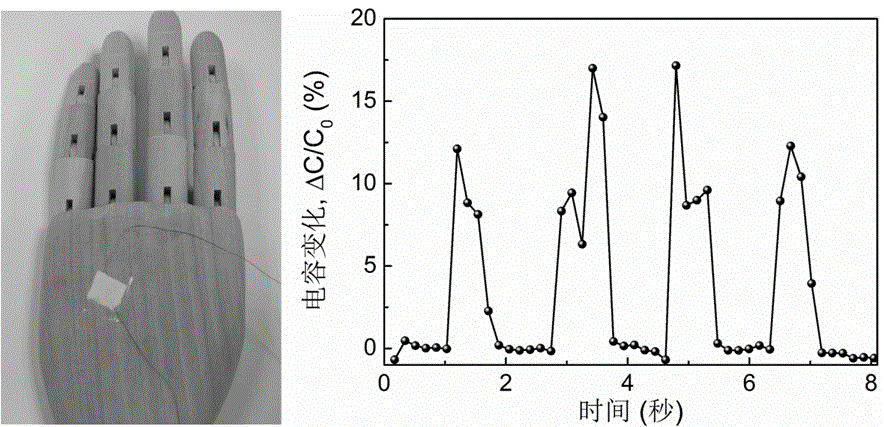

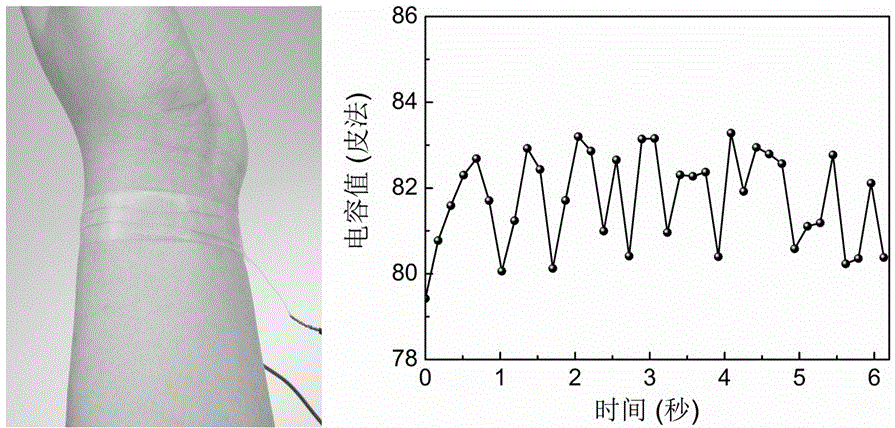

[0022] Add 1.5 mol∙L to 22 wt% sodium lauryl sulfate aqueous solution -1 of sodium chloride, and a total of 1 mol∙L was added to the obtained emulsion -1 The comonomers DMA and C18, in which the ratio of DMA and C18 monomers is 1:1, the polymerization reaction is co-initiated by ammonium persulfate and sodium metabisulfite at 55 °C, and the amount of ammonium persulfate is 0.79 mmol∙L -1 , the dosage of sodium metabisulfite is 1 mmol∙L -1 . The polymerization reaction time was 24 hours. The polymerized hydrogel can be 3D printed after melting. The specific printing parameters are: extrusion pressure 0.3 MPa, extrusion needle diameter 0.4 mm, extrusion temperature 45 °C, molding temperature 10 °C, printing speed 6 mm∙s -1 . Two layers of the same porous hydrogel ion-conducting layer were prepared respectively, and a layer of polyethylene film was embedded in the middle to construct a sandwich capacitive smart skin device.

[0023] figure 1 is a photograph of the printed...

Embodiment 2

[0027] Add 0.1 mol∙L to 1 wt% sodium lauryl sulfate aqueous solution -1 of sodium chloride, and a total of 1 mol∙L was added to the obtained emulsion -1 The comonomers DMA and C18, in which the ratio of DMA and C18 monomers is 2, the polymerization reaction is co-initiated by ammonium persulfate and sodium metabisulfite at 55 °C, and the amount of ammonium persulfate is 0.7 mmol∙L -1 , the dosage of sodium metabisulfite is 1 mmol∙L -1 . The polymerization reaction time was 15 hours. The polymerized hydrogel can be 3D printed after melting. The specific printing parameters are: extrusion pressure 0.7 MPa, extrusion needle diameter 0.01 mm, extrusion temperature 90 °C, molding temperature 80 °C, printing speed 10 mm∙s -1 . Two layers of the same porous hydrogel ion-conducting layer were prepared respectively, and a layer of polyethylene film was embedded in the middle to construct a sandwich capacitive smart skin device.

Embodiment 3

[0029] Add 3 mol∙L to 30 wt% sodium lauryl sulfate aqueous solution -1 of sodium chloride, and then add a total of 3 mol∙L to the obtained emulsion -1 The comonomers DMA and C18, the ratio of DMA and C18 monomers is 0.5, the polymerization reaction is co-initiated by ammonium persulfate and sodium metabisulfite at 70 °C, and the amount of ammonium persulfate is 0.1 mmol∙L -1 , the dosage of sodium metabisulfite is 0.1 mmol∙L -1. The polymerization reaction time was 48 hours. The polymerized hydrogel can be 3D printed after melting. The specific printing parameters are: extrusion pressure 0.5 MPa, extrusion needle diameter 1 mm, extrusion temperature 50°C, molding temperature 20°C, printing speed 0.1 mm∙s -1 . Two layers of the same porous hydrogel ion-conducting layer were prepared respectively, and a layer of polystyrene film was embedded in the middle to construct a sandwich-type capacitive smart skin device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com