Self-healing capacitive smart skin with high sensitivity and preparation method thereof

A smart skin, high-sensitivity technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problem of difficult to achieve weak pressure response, complete self-healing effect of bionic human skin, and dehydration failure. and other problems, to achieve the effect of broad industrial application prospects, easy mass production, and short production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Prepare 100 mL of 0.01 mol∙mL separately -1 Calcium chloride aqueous solution and equal concentration of sodium carbonate aqueous solution, add and dissolve 0.01 mol∙mL in the calcium chloride aqueous solution -1 of polyacrylic acid, added and dissolved 0.1 mg∙mL in sodium carbonate aqueous solution -1 The sodium alginate solution of sodium alginate was added dropwise to the aqueous solution of polyacrylic acid and calcium chloride at a speed of 10 mL∙min -1 , obtain a composite polyelectrolyte hydrogel, prepare two layers of the same polyelectrolyte hydrogel respectively, and embed a layer of polyethylene film in the middle to construct a sandwich-type capacitive smart skin device.

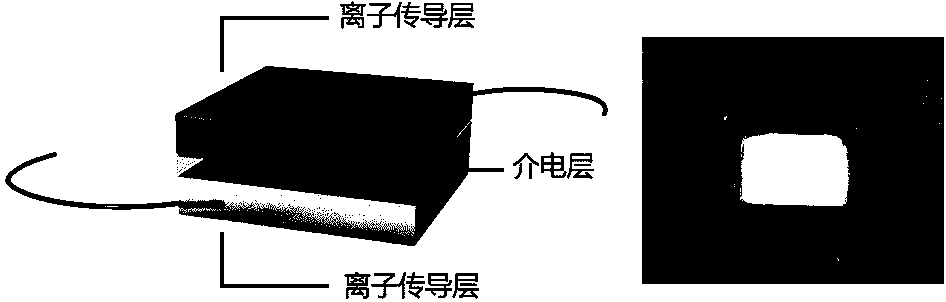

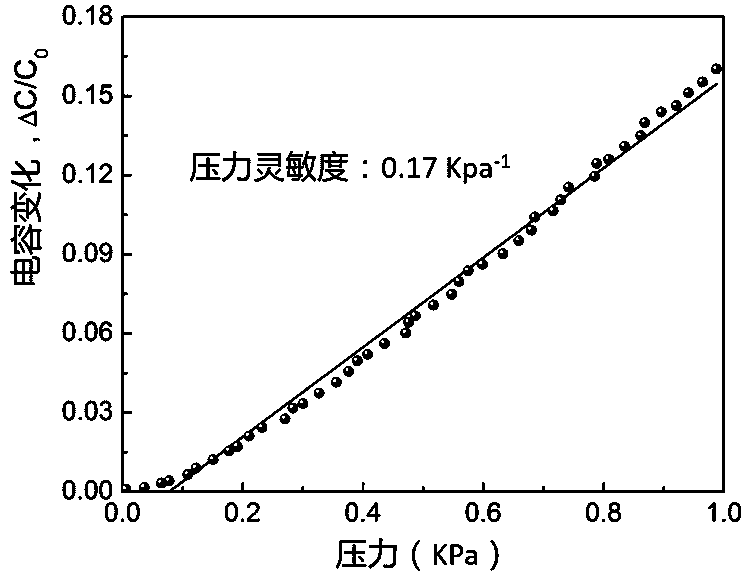

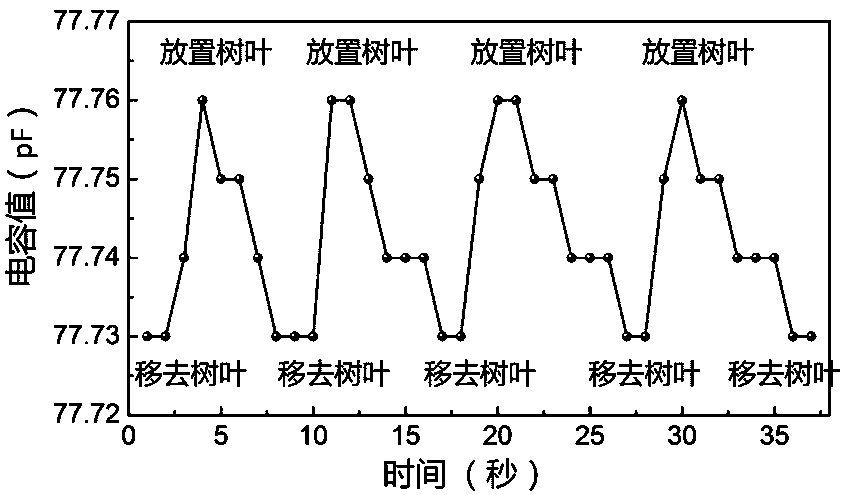

[0027] figure 1 The schematic diagram on the left shows the structure of the smart skin, and the picture on the right is a photo of the smart skin. The upper and lower ion conducting layers are calcium carbonate and sodium alginate cross-linked polyacrylic acid, a new type of hydrogel ma...

Embodiment 2

[0034] Prepare 100 mL of 1 mol∙mL separately -1 Calcium chloride aqueous solution and equal concentration of sodium carbonate aqueous solution, add and dissolve 1 mol∙mL in the calcium chloride aqueous solution -1of polyacrylic acid, added and dissolved 5 mg∙mL in sodium carbonate aqueous solution -1 The sodium alginate solution was added dropwise to the aqueous solution of polyacrylic acid and calcium chloride at a speed of 0.1 mL∙min -1 , obtain a composite polyelectrolyte hydrogel, prepare two layers of the same polyelectrolyte hydrogel respectively, and embed a layer of polypropylene film in the middle to construct a sandwich-type capacitive smart skin device.

Embodiment 3

[0036] Prepare 100 mL of 5 mol∙mL separately -1 Calcium chloride aqueous solution and equal concentration of sodium carbonate aqueous solution, add and dissolve 5 mol∙mL in the calcium chloride aqueous solution -1 of polyacrylic acid, added and dissolved 1 mg∙mL in sodium carbonate aqueous solution -1 The sodium alginate solution was added dropwise to the aqueous solution of polyacrylic acid and calcium chloride at a certain speed, and the speed was 5 mL∙min -1 , obtain a composite polyelectrolyte hydrogel, prepare two layers of the same polyelectrolyte hydrogel respectively, and embed a layer of polyacrylate tape in the middle to construct a sandwich-type capacitive smart skin device.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com