FDM rapid forming system

A fast, hardware system technology, applied in 3D object support structure, additive manufacturing, processing and manufacturing, etc., can solve problems such as the unsteady operation of the spinneret, the inability of the print head to adapt to the tolerance, the spinneret winding and looping, etc. Experience the effects of smooth, stuck-free, and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

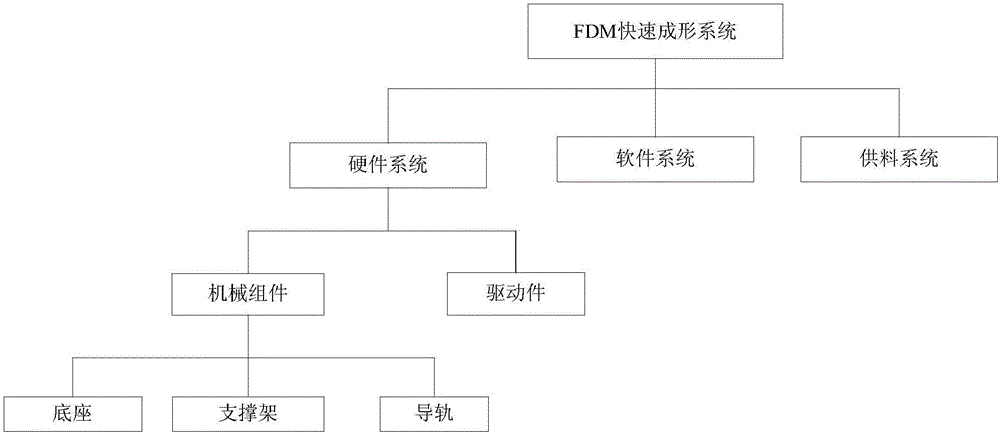

[0025] refer to figure 1 , a FDM rapid prototyping system, including a hardware system, a software system and a feeding system, the hardware system is composed of mechanical components and driving parts, the mechanical components include a base, a support frame, the support frame is fixed on the base, and the top of the support frame is respectively set X Direction and Y guide rails, on which the print head and the driver for driving the print head movement are arranged.

[0026] In the FDM rapid prototyping system of Example 1, the print head can better adapt to consumables with large diameter tolerances, the printing experience is smoother, and the filament output is more stable; in this embodiment, the printing area is increased, the printing speed is accelerated, and the body has high precision. High positioning accuracy, more stable operation, comes with wire reel fixing frame, the wire reel is installed on the fixing frame, which can effectively prevent the wire jam prob...

Embodiment 2

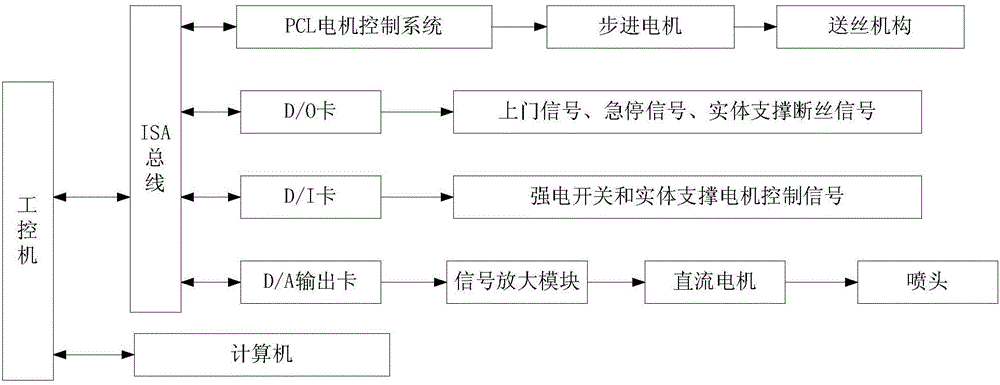

[0029] refer to figure 1 , differs from the above-mentioned embodiments in that the driving element is a stepper motor that converts pulse signals into corresponding angular displacements.

[0030] The energization mode of the stepper motor rotor and the stator winding of the present embodiment can be single-phase three-shot energization, and each shot of unidirectional three-shot energization has only one phase winding coil energization, and three shots complete a cycle, and the step torque angle of the stepper motor is 30°. The energization mode of the stepper motor rotor and the stator winding of the present embodiment can also be two-phase three-shot energization, each shot of the two-phase three-shot energization has two-phase winding energization, and the step moment angle of the stepper motor is 30°. The energization mode of the rotor and the stator winding of the stepping motor in this embodiment can also be single and double six-step energization, and the stepping mo...

Embodiment 3

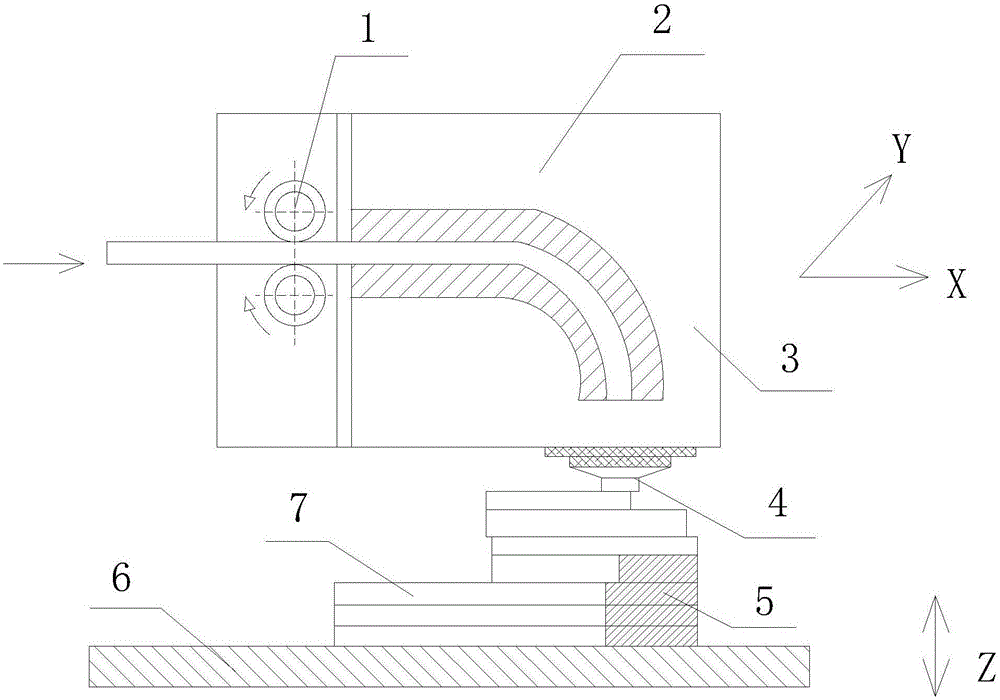

[0033] FDM rapid prototyping system such as figure 2 As shown, the FDM system generally uses low-melting filamentary materials, such as wax filaments or ABS plastic filaments, which do not use high-energy-density lasers as heat sources, and only need to use electric heating in the nozzle 2 to heat the filaments. molten state. It will be quite difficult if a material with a high melting point is used. The FDM rapid prototyping system of Example 3 mainly includes five parts: nozzle 2 , wire feed wheel 1 , motion mechanism, heater 3 , and base 6 . The material is heated and melted in the nozzle 2. There is a nozzle 4 at the bottom of the nozzle 2 for the molten material to be extruded under a certain pressure. When the nozzle 2 moves along the section profile of the part and the filling track, the material is extruded, bonded with the previous layer and blown in the air. Rapid solidification in the medium, so that the solid parts can be obtained repeatedly. The wire feed whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com