A kind of 3D printing method of polyether ether ketone and printing sample thereof

A polyetheretherketone, 3D printing technology, applied in the field of 3D printing, can solve the problems of limited application and poor shape memory performance of polyetheretherketone samples, and achieve a wide range of applications, high mechanical strength, and strong practicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

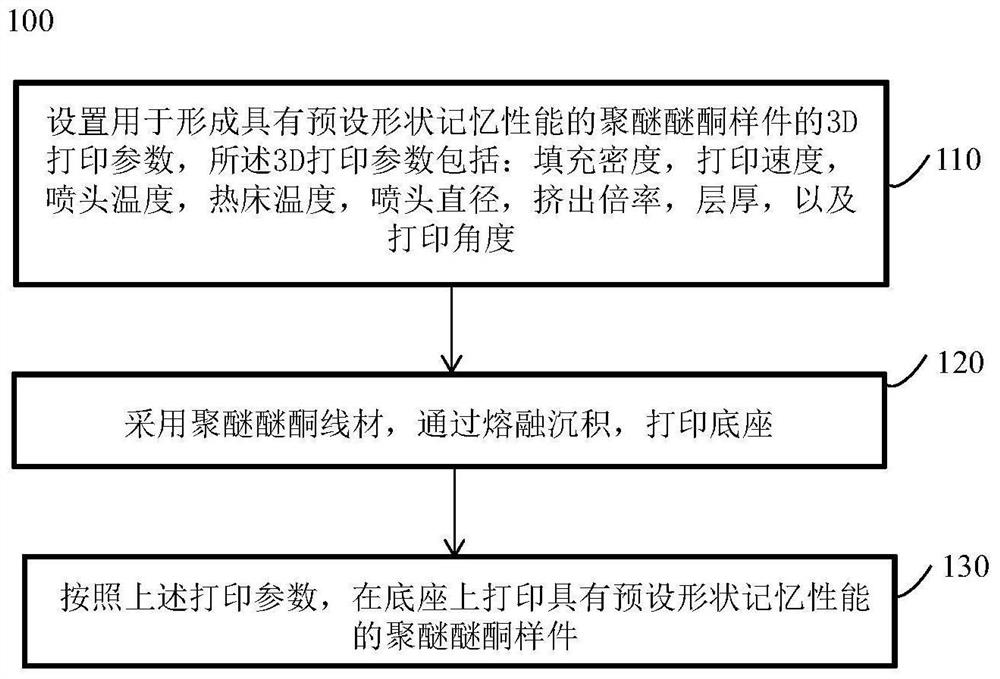

[0036] A 3D printing method 100 of polyether ether ketone, such as figure 1 shown, including:

[0037] Step 110, setting the 3D printing parameters used to form the polyetheretherketone sample with preset shape memory properties, the 3D printing parameters include: filling density, printing speed, nozzle temperature, hot bed temperature, nozzle diameter, extrusion Magnification, layer thickness, and printing angle;

[0038] Step 120, using polyetheretherketone wire to print the base through fused deposition;

[0039] Step 130 , according to the above printing parameters, print the polyetheretherketone sample with preset shape memory performance on the base.

[0040] The verification method that the polyetheretherketone sample obtained by the 3D printing method of polyetheretherketone has preset shape memory performance can be:

[0041] The polyetheretherketone sample is naturally cooled, and the shape of the sample is the original shape at this time; the sample is heated to...

example 1

[0059] (1) Carry out thermal pretreatment to the polyether ether ketone wire rod with controllable shape memory performance, by putting the polyetheretherketone wire rod into a vacuum oven, the temperature is 160 ℃ under vacuum condition and heating for 2 hours to remove the inside of the wire rod Moisture; set the filling density of 3D printing parameters to 100%, printing speed to 30mm / s, nozzle temperature to 410°C, hot bed temperature to 110°C, nozzle diameter to 0.4mm, extrusion ratio to 1, print layer thickness to 0.1mm, and print angle to 45° °; Then perform zeroing operation and pre-heating treatment on the nozzle and heat bed before printing.

[0060] (2) Printing: When the temperature of the nozzle of the printer and the hot bed reaches the preset temperature, the slicing of the 3D modeling sample requires pre-printing a layer of large base, and then printing according to the 3D printing parameters.

[0061] After printing the polyetheretherketone sample with control...

example 2

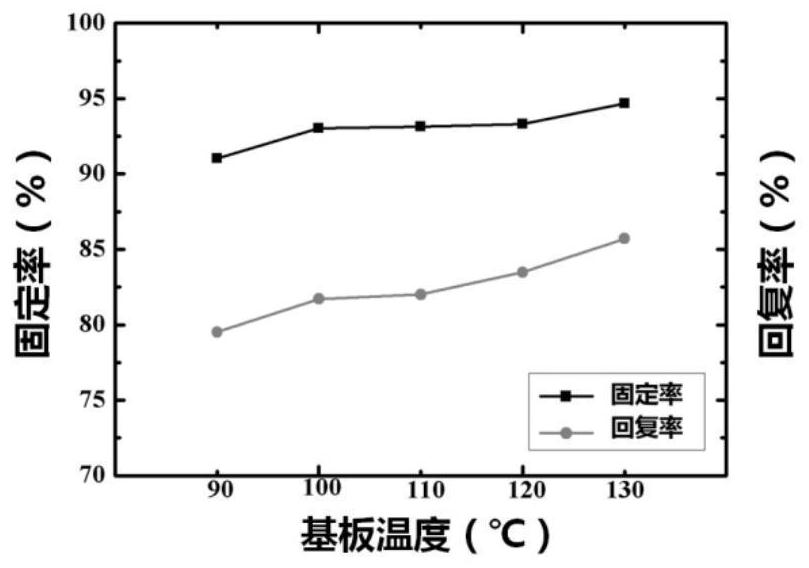

[0064] (1) Carry out thermal pretreatment on the polyetheretherketone wire with controllable shape memory performance, by putting the polyetheretherketone wire into a vacuum oven and heating it at 160°C for 2 hours under vacuum conditions to remove the inside of the wire Moisture; set the filling density of 3D printing parameters to 100%, print speed to 30mm / s, nozzle temperature to 410°C, hot bed temperature to 90°C, 100°C, 110°C, 120°C, 130°C, nozzle diameter to 0.4mm, extrusion The magnification is 1 times, the printing layer thickness is 0.1mm, and the printing angle is 45°; then the nozzle and the hot bed are reset to zero and preheated before printing.

[0065] (2) Printing: When the temperature of the nozzle of the printer and the hot bed reaches the preset temperature, the slicing of the 3D modeling sample requires pre-printing a layer of large base, and then printing according to the 3D printing parameters.

[0066] After the PEEK sample with controllable shape memory...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com