Light-shading composite membrane and preparation method thereof

A composite film and composite structure technology, applied in the application, shading materials and application fields, can solve the problems such as the inability to meet the development trend of simplicity and lightness of decorative textiles, the deterioration of drape performance and air permeability, and the influence of shading effect, so as to achieve a lightweight structure. , colorful, strong shading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0057] S1. Prepare reflective particles and light-absorbing particles.

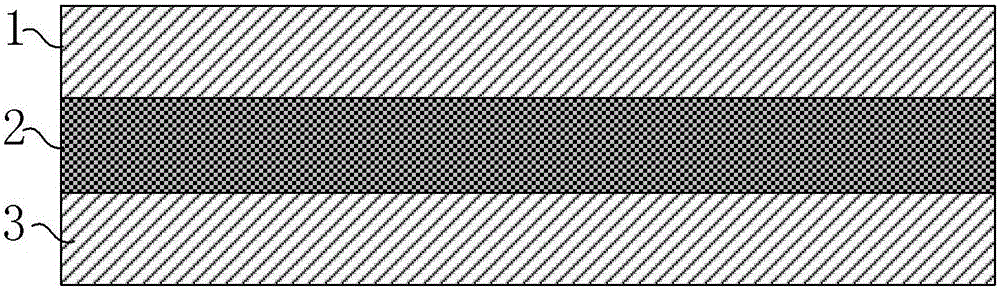

[0058] Add 30 parts of titanium dioxide with a particle size of 0.7 microns, add 20 parts of an environmentally friendly organic ester plasticizer, stir and mix evenly, add 100 parts by weight of dried POE resin, stir and mix, add a twin-screw granulator to granulate, and obtain reflective For white particles, 25 parts by weight of high-black carbon black powder with a particle size of 0.5 microns is added to 46 parts of environmentally friendly organic ester plasticizers and stirred evenly, then 100 parts of dried POE resin is added to mix the mixture, and twin-screw granulation is added. Machine granulation to obtain light-absorbing black particles.

[0059] S2. Add the light-reflecting particles and the light-absorbing particles into the raw resin and mix evenly.

[0060] The dried EVA resin raw material is mixed with the light-reflecting particles and the light-absorbing particles respectively; the m...

preparation Embodiment 2

[0067] S1. Prepare reflective particles and light-absorbing particles.

[0068] This step is the same as the first embodiment, so it will not be described in detail.

[0069] S2. Add the light-reflecting particles and the light-absorbing particles into the raw resin and mix evenly.

[0070] Mix the dried EVA resin raw material with reflective particles and light-absorbing particles respectively; the mixing weight ratio of EVA resin and light-reflecting particles is 100:50, and the mixing weight ratio of EVA resin and light-absorbing particles is 100:50

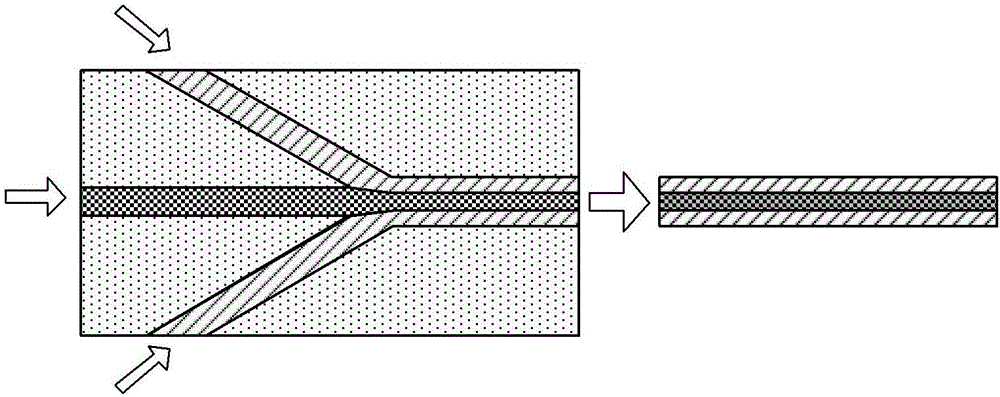

[0071] S3, integrally extruding the resin mixed with light-reflecting particles and the resin mixed with light-absorbing particles.

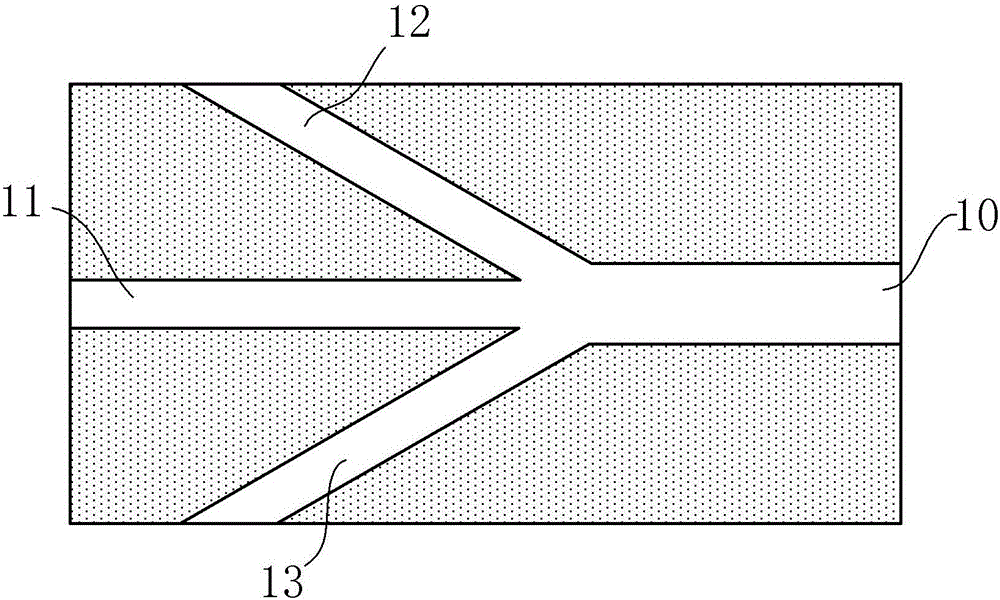

[0072] On the basis of thorough mixing, the mixed materials are respectively added to the three-input co-extruder to ensure that the mixed resin of the reflective particles is guided to the upper and lower areas of the extrusion die, and the mixed resin of the light-absorbing particles is direc...

preparation Embodiment 3

[0074] S1. Prepare reflective particles and light-absorbing particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com