PEVA membrane hot pressing compounding machine

A composite machine and pressing device technology, applied in the field of composite machines, can solve the problems of glue waste and environmental protection, and achieve the effects of cost reduction, smooth surface and high composite efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

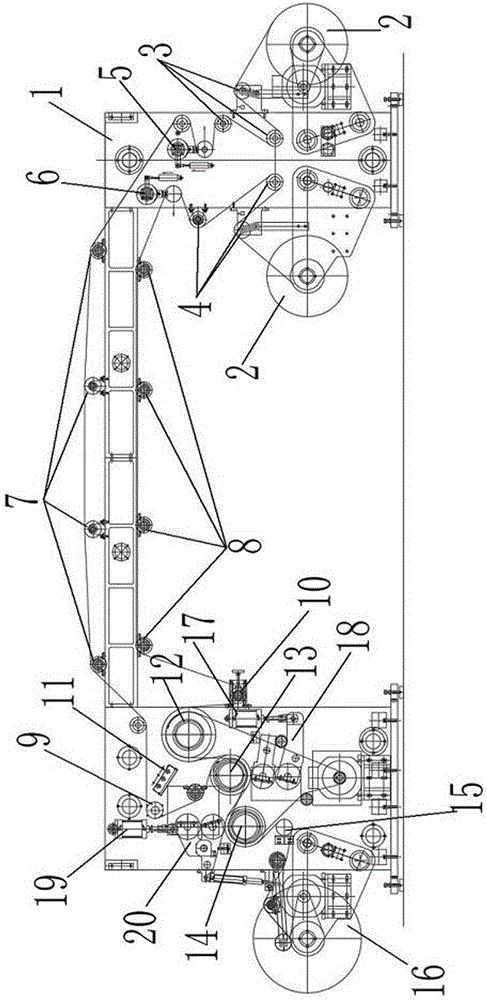

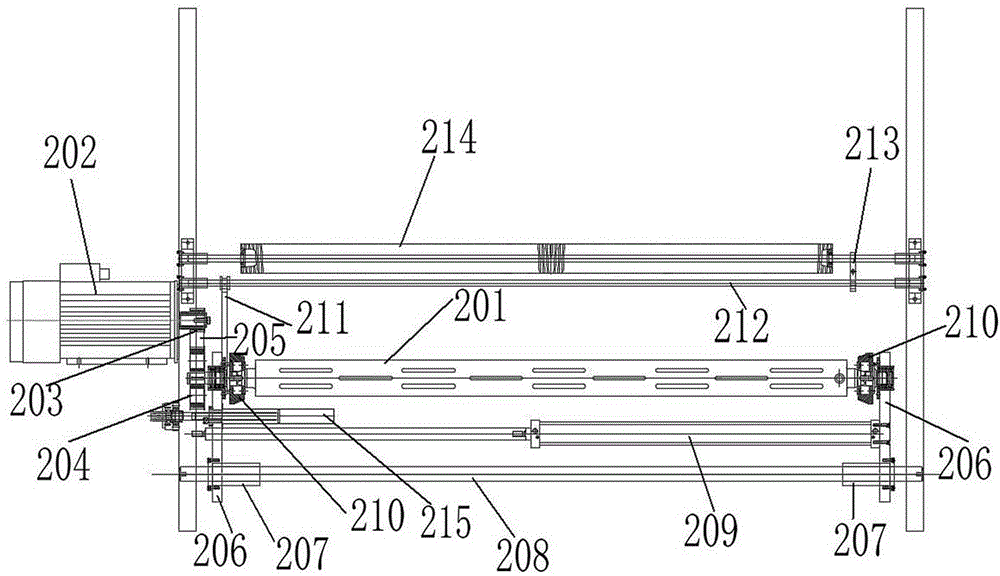

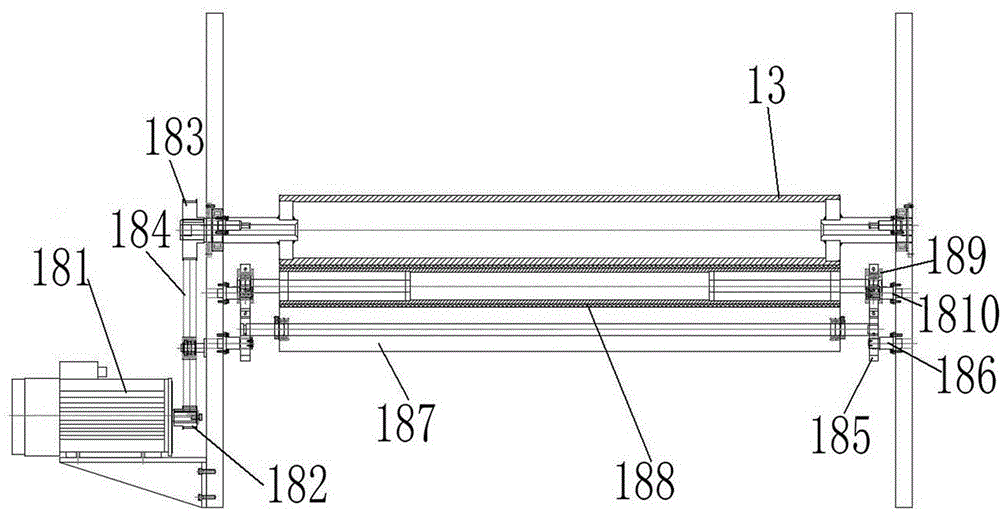

[0030] Attached below figure 1 to the attached Figure 4 The present invention will be further described.

[0031]A PEVA film hot-press laminating machine, comprising: a frame 1; two unwinding mechanisms 2, which are respectively installed on the front end of the frame 1, one unwinding mechanism 2 places a PE film substrate, and the other unwinding mechanism 2 places a plated film. Aluminum PET film substrate or nylon film substrate; several transition rollers I 3, several transition rollers II 4, several transition rollers III 7 and several transition rollers IV 8, which are respectively installed in rotation on the frame 1; tension rollers I 5 and Tension roller Ⅱ 6, respectively rotated and installed on frame 1, is used to generate tension on the base material; regulating roller Ⅰ 9 and regulating roller Ⅱ 10, rotatably mounted on frame 1, the axes of regulating roller Ⅰ 9 and regulating roller Ⅱ 10 The position is adjusted horizontally until the roller surface of the adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com