Free air tire

A non-pneumatic tire and tire technology, applied to the reinforcement layer of pneumatic tires, tire parts, transportation and packaging, etc., can solve the problems of non-pneumatic tires such as uneven ground contact marks, low handling comfort, etc., and improve the handling safety performance , Improving the deformation recovery ability and buffering ability, and the effect of good bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In the following, the present invention will be specifically described through exemplary embodiments. It is to be understood, however, that elements, objects and characteristics of one embodiment may be beneficially incorporated in other embodiments without further recitation.

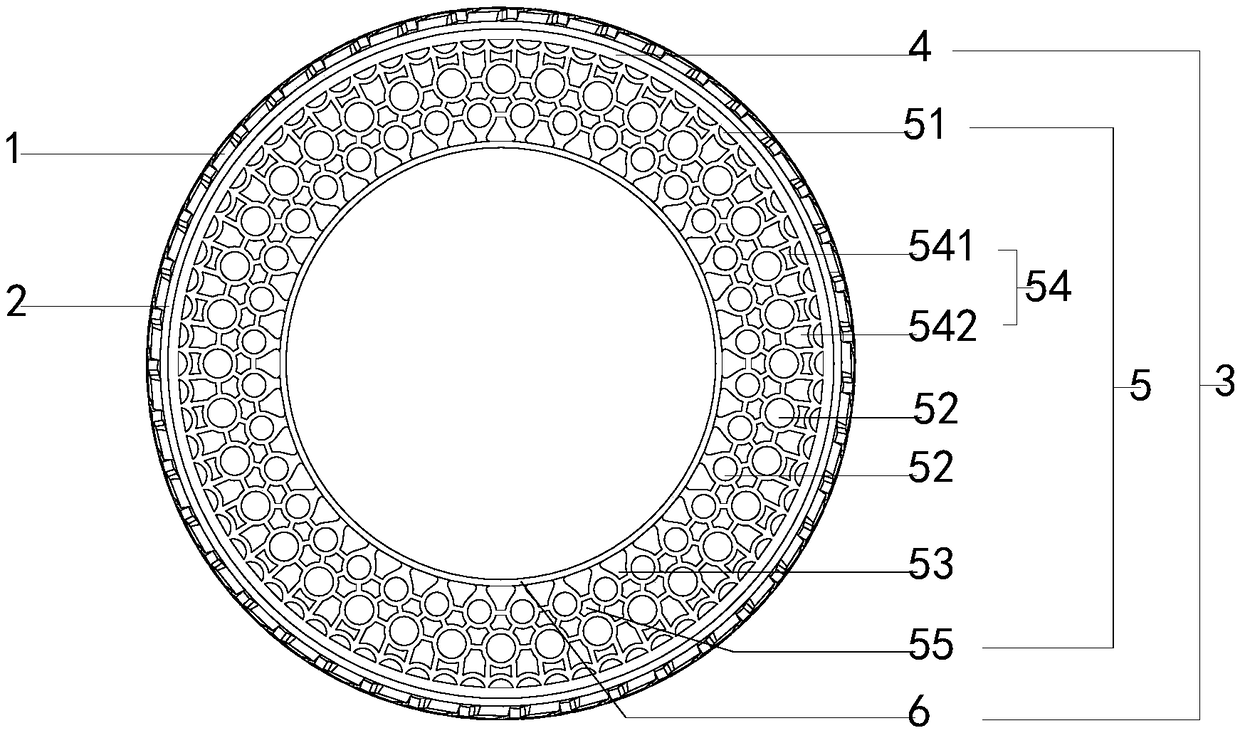

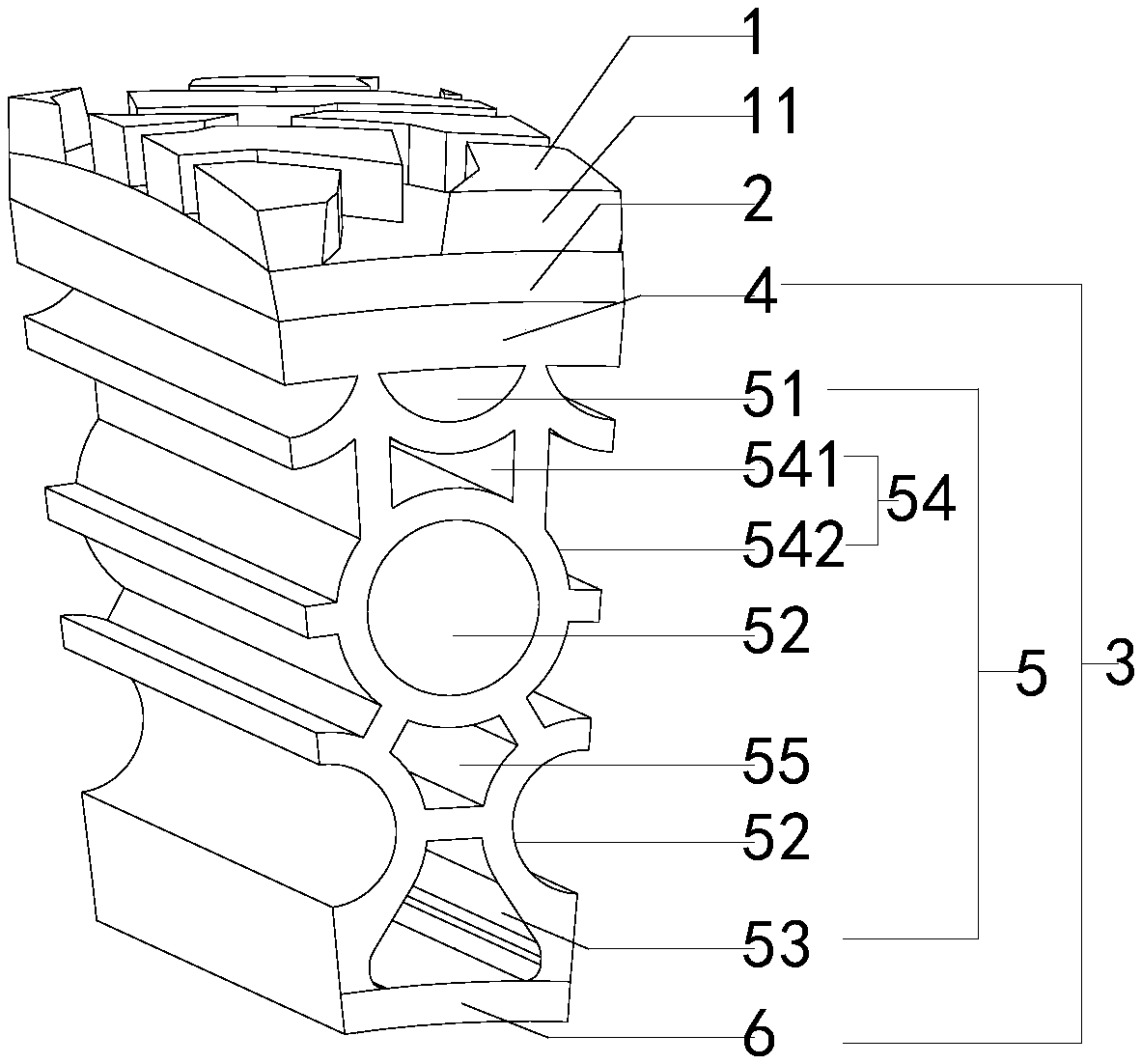

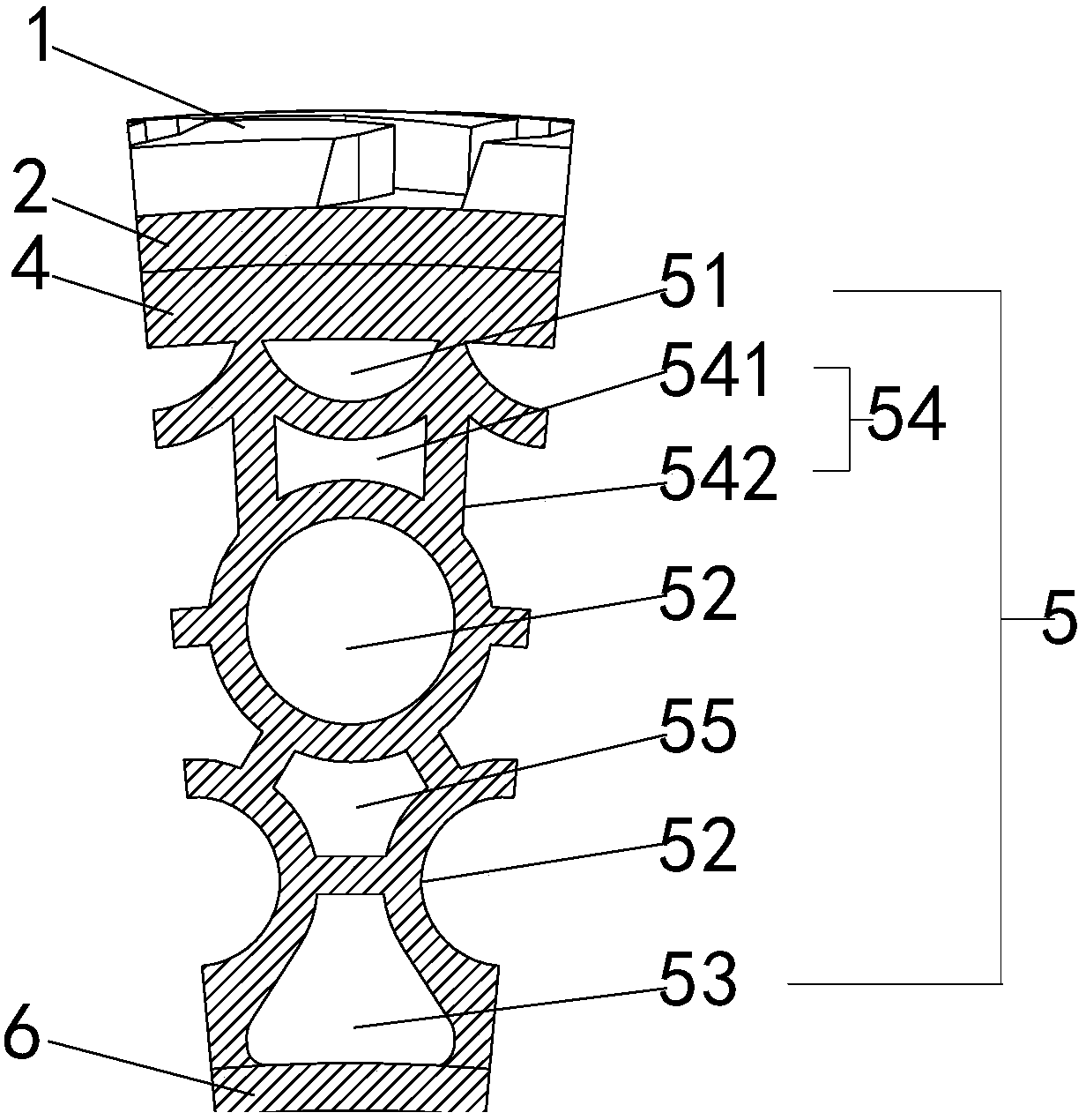

[0033] In the description of the present invention, it should be noted that the attached figure 1 The rotation axis of the middle tire is the axial direction, the circumferential direction is the circumferential direction, and the direction along the radius is the radial direction; and the direction along the increasing radius is outward, and the direction along the decreasing radius is inward; the axial section is perpendicular to the tire For the section of the rotating shaft, the circumferential section is the section passing through the tire rotating shaft and perpendicular to the circumferential direction, and the top of the axial section is the radially outer end surface of the axial secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com