Settling agent and method for rapidly settling solid substances in wet-process phosphoric acid

A wet-process phosphoric acid and sedimentation agent technology, applied in phosphorus compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of inability to obtain phosphoric acid, high bottom liquid height, incomplete sedimentation, etc., and achieve the reduction of scaling phenomenon and the effect of Good, the effect of shortening the settling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

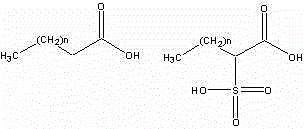

[0021] Embodiment 1: The sedimentation agent is by the synthetic fatty acid of 33 carbon chain lengths and α - Composition of sulfonated fatty acids. fatty acids and alpha - COO of sulfonated fatty acids - / SO 3 2- The ratio is 100:1, and the alkaline aqueous solution with a mass concentration of 10% is used as a sedimentation agent.

[0022] To 5000Kg / t (P 2 o 5 Add 1‰ of the specified sedimentation agent of the present invention to 24% industrial dilute phosphoric acid liquid, stir at 50°C for 60 minutes, and let it stand for 40 minutes after the stirring is completed. After testing, the removal rate of organic carbon particles reaches 95%, F - The removal rate reached 87%, Fe 3+ The removal rate reached 37%, Mg 2+ The removal rate reached 24%, Al 3+ The removal rate reaches 25%, Ca 2+ The removal rate reaches 70%, Si 4+ The removal rate reaches 13%, and the obtained wet-process phosphoric acid is clear and bright.

Embodiment 2

[0023] Embodiment 2: The sedimentation agent is by the synthetic fatty acid of 9 carbon chain lengths and α - Composition of sulfonated fatty acids. fatty acids and alpha - COO of sulfonated fatty acids - / SO 3 2- The ratio is 10:1, and it is made into an aqueous solution with a mass concentration of 10% as a sedimentation agent.

[0024] To 10000Kg / t (P 2 o 5 10% of the sedimentation agent specified in the present invention was added to 26% of the industrial dilute phosphoric acid solution, stirred at 53°C for 55 minutes, and left to stand for 10 minutes after the stirring was completed. After testing, the removal rate of organic carbon particles reached 90%, F - The removal rate reached 92%, Fe 3+ The removal rate reached 78%, Mg 2+ The removal rate reached 34%, Al 3+The removal rate reached 26%, Ca 2+ The removal rate reached 67%, Si 4+ The removal rate reaches 46%, and the obtained wet-process phosphoric acid is clear and bright.

Embodiment 3

[0025] Embodiment 3: The sedimentation agent is by carbon chain length be the synthetic fatty acid of 33 and α - Composition of sulfonated fatty acids. fatty acids and alpha - COO of sulfonated fatty acids - / SO 3 2- The ratio is 1:100, and the alkaline aqueous solution with a mass concentration of 10% is used as a sedimentation agent.

[0026] To 5000Kg / t (P 2 o 5 Add 1% of the specified sedimentation agent of the present invention to 24% industrial dilute phosphoric acid liquid, stir at 47°C for 70 minutes, and let it stand for 40 minutes after the stirring is completed. After testing, the removal rate of organic carbon particles reaches 95%, F - The removal rate reached 90%, Fe 3+ The removal rate reached 53%, Mg 2+ The removal rate reached 66%, Al 3+ The removal rate reached 46%, Ca 2+ The removal rate reached 78%, Si 4+ The removal rate reaches 43%, and the obtained wet-process phosphoric acid is clear and bright.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com