Preparation method of novel micro-nano prussian blue particles

A Prussian blue, micro-nano technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of affecting the properties of Prussian blue, it is difficult to control the size and shape of Prussian blue particles, and the reaction rate Quick and other problems, to achieve the effect of easy control of the operation process, easy popularization and use, and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Pipette 20mL 1mmol / L FeCl respectively 3 and 1mmol / L K 3 [Fe(CN) 6 ] Pour the two precursor solutions into a beaker, drop an appropriate amount of hydrochloric acid with a dropper to adjust the pH value of the mixed solution to 1-2, put the magnetron into the solution, and continuously stir the reaction on the magnetic stirring device for 24 hours, then put the reaction The micronano Prussian blue particles can be prepared by placing them in liquid solution, centrifuging and washing, and then drying them in an oven at 90°C.

Embodiment 2

[0015] The preparation method of this example is the same as that of Example 1, and the reaction time is controlled to be 48 hours. Under the condition that other conditions remain unchanged, micronano Prussian blue particles are also synthesized.

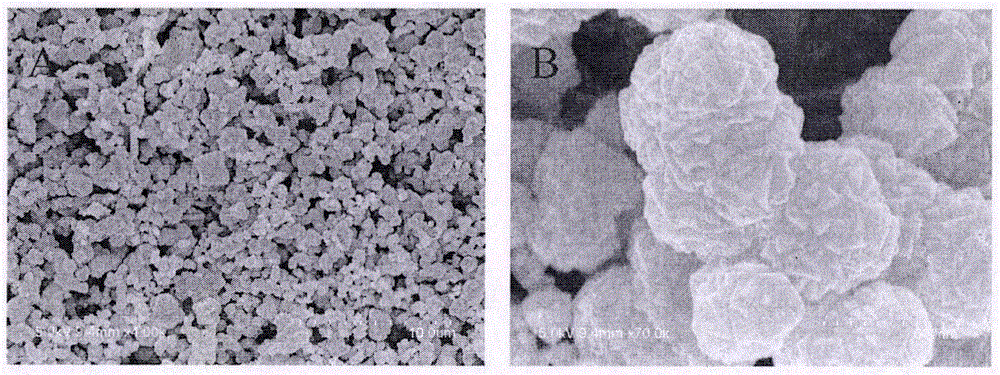

[0016] The characterization of the micronano Prussian blue particles synthesized according to the method of the present invention is shown in the appendix figure 1 shown

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com