Tin-antimony-selenium chalcogenide glass and preparation method thereof

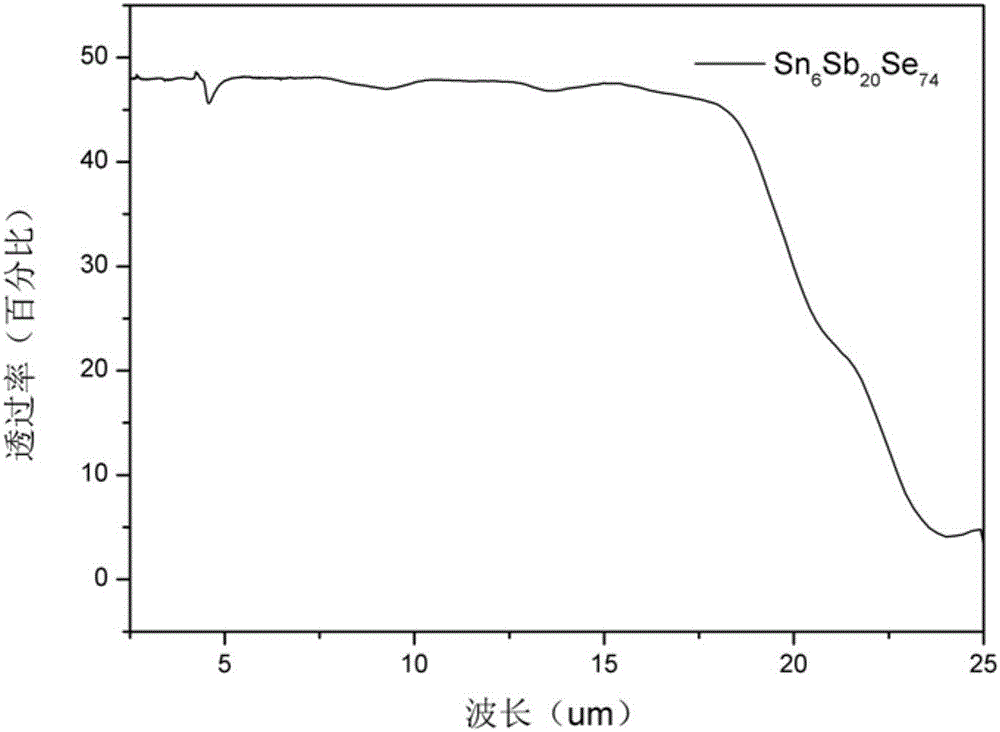

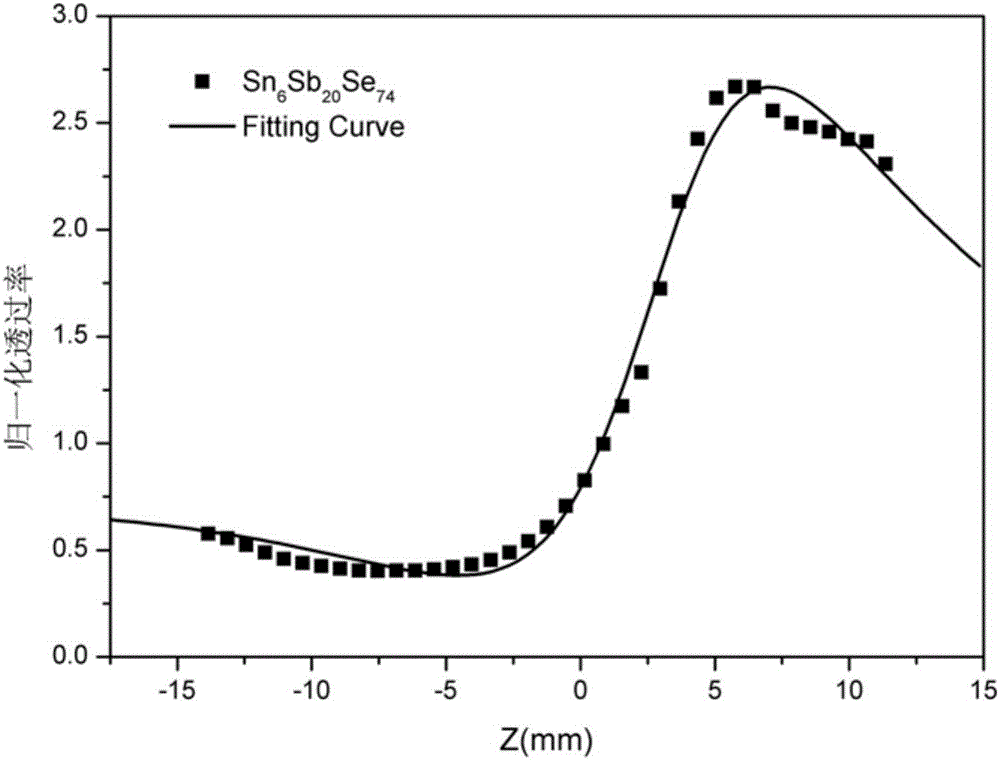

A technology of chalcogenide glass and sn-sb-se, which is applied in the field of Sn-Sb-Se chalcogenide glass and its preparation, and achieves good mid- and far-infrared transmittance and near-infrared transmittance, good glass-forming ability, and preparation method. Simple and actionable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] Four Sn-Sb-Se chalcogenide glasses with different proportions were selected as Examples 1-4, and two classic As-containing chalcogenide glasses (As 40 Se 60 and As 40 S 60 ) as Comparative Examples 1-2. The preparation method of the Sn-Sb-Se chalcogenide glass of each embodiment comprises the following steps:

[0026] 1) Dosing and vacuuming: use high-purity (>99.999%) elemental Sn, Sb and Se, carry out proportioning and weighing according to the ratio in the composition formula and mix them evenly, then put the mixed raw materials into the quartz tube, Vacuum to 10 -4 ~10 -6 Pa, then the raw material is packaged in a closed quartz tube;

[0027] 2) High-temperature melting and quenching: Put the quartz tube packaged with raw materials into a heating furnace for high-temperature melting. The heating temperature is 800-1000°C and the heating time is 12 hours. While melting at high temperature, continuously shake the quartz tube and heat it. After the end, obtain t...

Embodiment 1

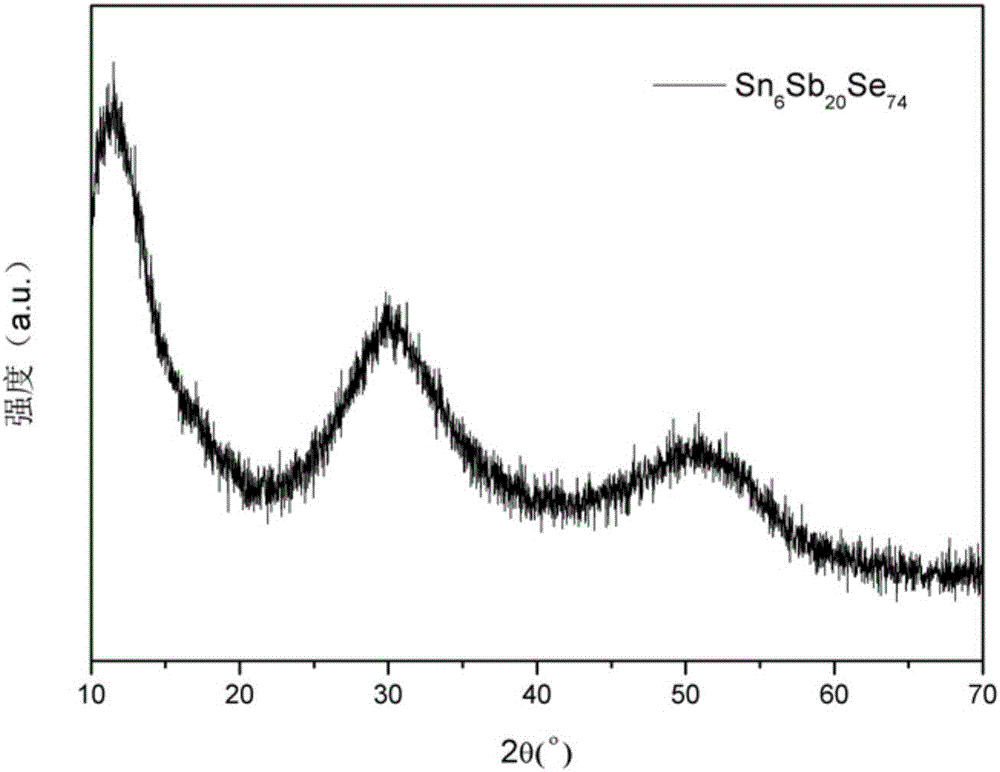

[0032] In the microstructure of the Sn-Sb-Se chalcogenide glass of Example 1, the percentage of the number of Sn-Se bonds to the total number of chemical bonds is 16.45%, and the percentage of the number of Sb-Se bonds to the total number of chemical bonds is 56.33% , the percentage of the number of Se-Se bonds in the total number of chemical bonds is 27.22%; in the microstructure of the Sn-Sb-Se chalcogenide glass of Example 2, the percentage of the number of Sn-Se bonds in the total number of chemical bonds is 23.73% %, the percentage of the number of Sb-Se bonds in the total number of chemical bonds is 44.67%, and the percentage of the number of Se-Se bonds in the total number of chemical bonds is 31.6%; the microscopic structure of the Sn-Sb-Se chalcogenide glass of Example 3 In the structure, the number of Sn-Se bonds accounts for 25.55% of the total number of chemical bonds, the percentage of Sb-Se bonds accounts for 57.99% of the total number of chemical bonds, and the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com