A kind of preparation method of novel zno nano sheet structure coating

A nano-flaky, new technology, applied in the field of preparation of new ZnO nano-flaky structure coatings, to achieve the effect of green chemical technology, low cost, and easy to realize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

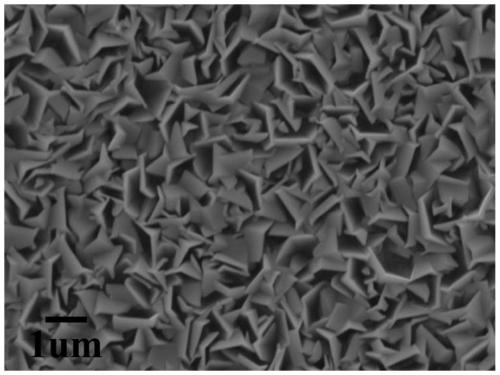

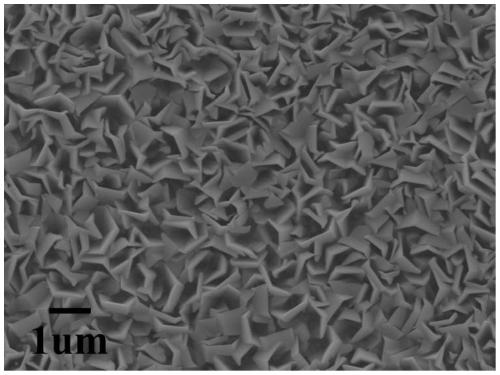

[0028] First, a 0.025mol / L ZnO seed layer sol was prepared by the sol-gel method; then the ZnO seed layer film was prepared by pulling the film on ITO glass by dipping and pulling method, and the film was placed in a muffle furnace and kept at 250°C Sinter for 2 hours to obtain the ZnO seed layer film; then put the prepared ZnO seed layer film substrate vertically into the configured 0.1mol / L ZnO growth solution, treat it in a constant temperature water bath at 75°C for 4 hours, and wait for the hydrothermal After the reaction, the corrosion reaction was continued for 5 days in the original growth solution at a normal temperature of 20° C., and the sample was taken out to obtain a new type of ZnO nanosheet structure coating.

Embodiment 2

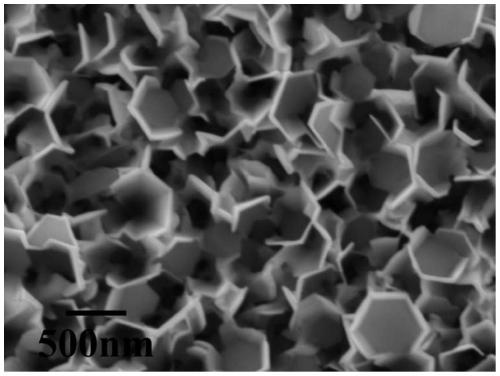

[0030] First, a 0.025mol / L ZnO seed layer sol was prepared by the sol-gel method; then the ZnO seed layer film was prepared by pulling the film on ITO glass by dipping and pulling method, and the film was placed in a muffle furnace and kept at 250°C Sinter for 2 hours to obtain the ZnO seed layer film; then put the prepared ZnO seed layer film substrate vertically into the configured 0.025mol / L ZnO growth solution, treat it in a constant temperature water bath at 75°C for 4 hours, and wait for the hydrothermal After the reaction, the corrosion reaction was continued for 7 days in the original growth solution at a normal temperature of 20° C., and the sample was taken out to obtain a new type of ZnO nanosheet structure coating.

Embodiment 3

[0032] First, a 0.025mol / L ZnO seed layer sol was prepared by the sol-gel method; then the ZnO seed layer film was prepared by pulling the film on ITO glass by dipping and pulling method, and the film was placed in a muffle furnace and kept at 250°C Sinter for 2 hours to obtain the ZnO seed layer film; then put the prepared ZnO seed layer film substrate vertically into the configured 0.1mol / L ZnO growth solution, treat it in a constant temperature water bath at 75°C for 4 hours, and wait for the hydrothermal After the reaction, the corrosion reaction was continued for 10 days in the original growth solution at a normal temperature of 20° C., and the sample was taken out to obtain a new type of ZnO nanosheet structure coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com