Biomass synthetic resin filtrate reducer, preparation method thereof and water-based drilling fluid filtrate reducer

A technology for synthetic resins and fluid loss reducers, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of poor biodegradability, poor degradability, application limitations, etc., and achieve excellent salt resistance, Low cost, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] In parts by weight, in a four-port reactor with a reflux device, add 80 parts of furfuryl alcohol, 1 part of water, and 100 parts of furfural successively, stir for 10 minutes, and have a stirring speed of 250 rpm to obtain a mixture 1; keep the stirring speed at 250 rpm without Change, add 25 parts of sodium metabisulfite to mixture 1 in 5 times, each addition is 5 parts, and stir for 10 minutes to obtain mixture 2; add 40 parts of anhydrous sodium sulfite to mixture 2 in 4 times, each addition For 10 parts, stir for 10 minutes to obtain mixture 3; raise the temperature to 60°C, react for 30 minutes, then adjust the temperature of the reactor, raise the temperature to 95°C, and react for 20 minutes to obtain mixture 4; add 3 parts of Water, water was added 4 times in total, and then the reaction was continued for 60 minutes to discharge the material to obtain a biomass synthetic resin fluid loss control agent.

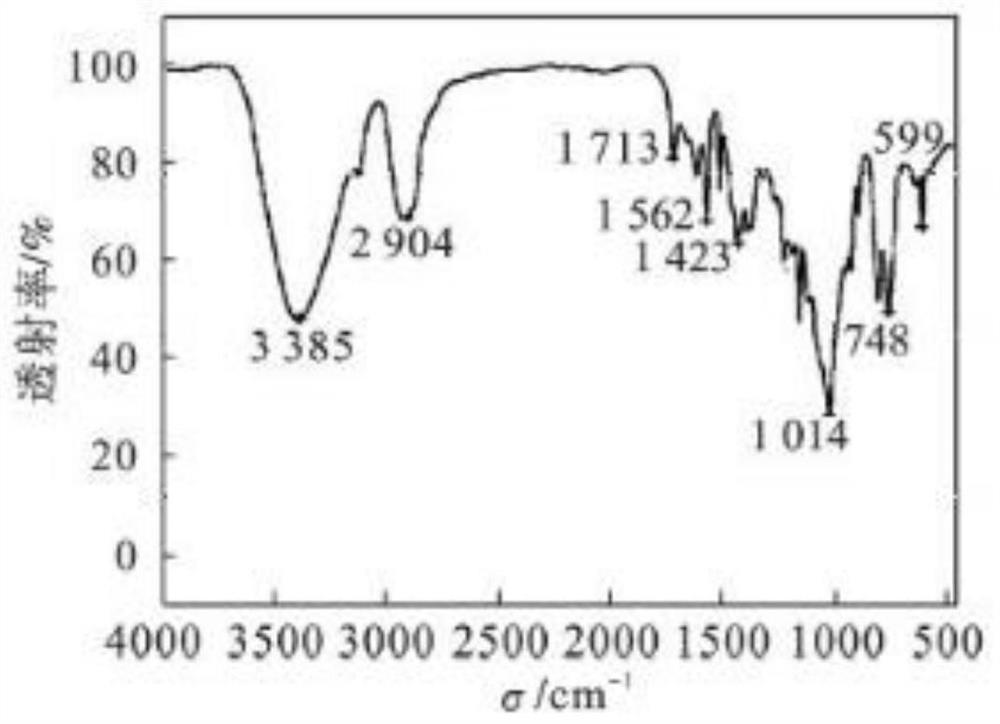

[0056] The biomass synthetic resin fluid loss reducer pre...

Embodiment 2

[0058] In parts by weight, in a four-port reactor with a reflux device, add 90 parts of furfuryl alcohol, 1 part of water, and 150 parts of furfural successively, stir for 10 minutes, and stir at a speed of 300 rpm to obtain a mixture 1; keep the stirring speed at 300 rpm without Change, add 40 parts of sodium metabisulfite to mixture 1 in 4 times, each addition is 10 parts, and stir for 10 minutes to obtain mixture 2; add 60 parts of anhydrous sodium sulfite to mixture 2 in 5 times, each addition For 12 parts, stir for 10 minutes to obtain mixture 3; raise the temperature to 70°C, react for 30 minutes, then adjust the temperature of the reactor, raise the temperature to 105°C, and react for 30 minutes to obtain mixture 4; add 3 parts of Water, water was added 4 times in total, and then the reaction was continued for 90 minutes to discharge the material to obtain a biomass synthetic resin fluid loss control agent.

Embodiment 3

[0060] In parts by weight, in a four-port reaction kettle with a reflux device, add 95 parts of furfuryl alcohol, 1 part of water, and 180 parts of furfural successively, stir for 20 minutes, and have a stirring speed of 250 rpm to obtain a mixture 1; keep a stirring speed of 250 rpm without Change, add 60 parts of sodium metabisulfite to mixture 1 in 5 times, each addition is 12 parts, stir for 20 minutes, to obtain mixture 2; add 40 parts of anhydrous sodium sulfite to mixture 2 in 4 times, each addition 10 parts, stirred for 20 minutes to obtain mixture 3; raise the temperature to 65°C, react for 30 minutes, then adjust the temperature of the reactor, raise the temperature to 100°C, and react for 30 minutes to obtain mixture 4; add 3 parts of Water, water was added 4 times in total, and then the reaction was continued for 90 minutes to discharge the material to obtain a biomass synthetic resin fluid loss control agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com