A kind of biological polysaccharide-based water-based polyurethane material and preparation method thereof

The technology of polyurethane material and biological polysaccharide is applied in the field of biological polysaccharide-based water-based polyurethane material and its preparation, which can solve the problems of low catalytic efficiency of catalyst, empty bottom of pavement, poor biocompatibility, etc., and achieves non-toxic preparation method and equipment. The effect of low requirements and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

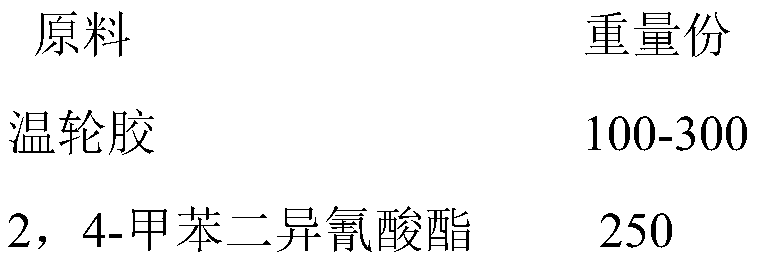

[0032] A biological polysaccharide-based water-based polyurethane material is prepared from the following raw materials in proportions by weight:

[0033]

[0034] A kind of method utilizing above-mentioned raw material to prepare biological polysaccharide-based waterborne polyurethane material, its step is:

[0035] 1) In a glass reactor equipped with an electric stirrer, a reflux condenser, and a digital display thermometer, add 300 parts by weight of Wenlun glue, set the stirring rate to 100 rpm, and vacuumize at 120°C under stirring conditions 1h;

[0036] 2) After cooling to about 75°C, add 250 parts by weight of 2,4-toluene diisocyanate and 50 parts by weight of isophorone diisocyanate in turn, then dropwise add 30 parts by weight of triethanolamine and 10 parts by weight of stannous octoate, at 75°C Stirring for 0.5h, the rate of stirring is 100 rpm;

[0037] 3) Add 12 parts by weight of 1,4-butanediol, 100 parts by weight of acetone and 10 parts by weight of n-pen...

Embodiment 2

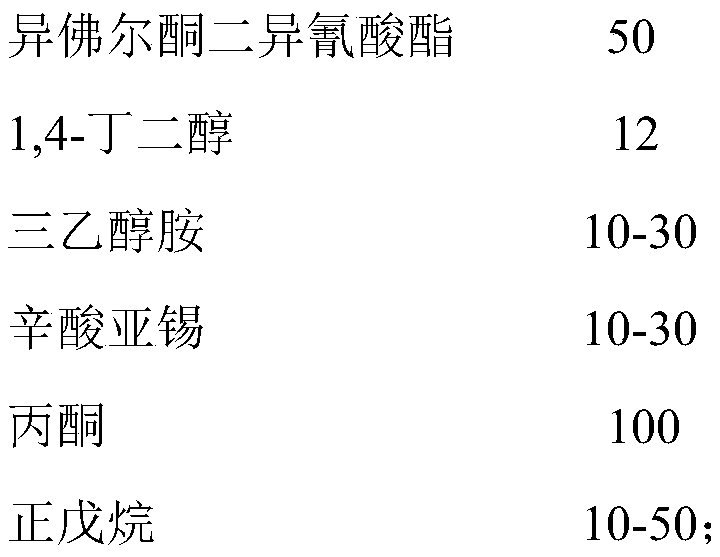

[0047] A biological polysaccharide-based water-based polyurethane material is prepared from the following raw materials in proportions by weight:

[0048]

[0049] A kind of method utilizing above-mentioned raw material to prepare biological polysaccharide-based waterborne polyurethane material, its step is:

[0050] 1) In a glass reactor equipped with an electric stirrer, a reflux condenser, and a digital display thermometer, add 200 parts by weight of Wenlun glue, set the stirring rate to 200 rpm, and vacuumize at 120°C under stirring conditions 1h;

[0051] 2) After cooling to about 75°C, add 250 parts by weight of 2,4-toluene diisocyanate and 50 parts by weight of isophorone diisocyanate in turn, then dropwise add 30 parts by weight of triethanolamine and 10 parts by weight of stannous octoate, at 75°C Stirring for 0.5h, the rate of stirring is 200 rpm;

[0052] 3) Add 12 parts by weight of 1,4-butanediol, 100 parts by weight of acetone and 10 parts by weight of n-pen...

Embodiment 3

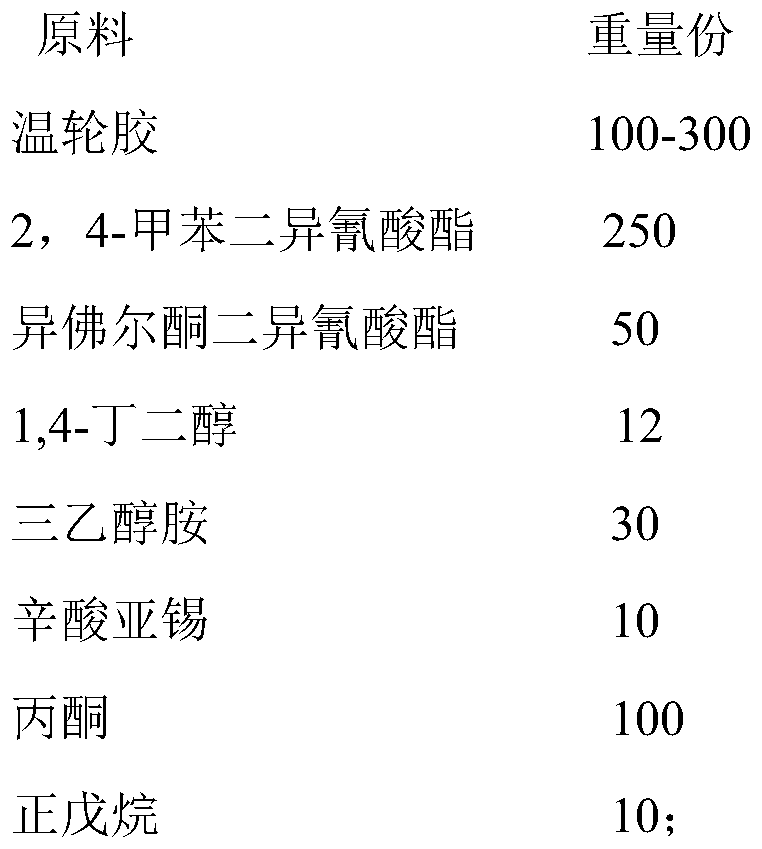

[0062] A biological polysaccharide-based water-based polyurethane material is prepared from the following raw materials in proportions by weight:

[0063]

[0064]

[0065] A kind of method utilizing above-mentioned raw material to prepare biological polysaccharide-based waterborne polyurethane material, its step is:

[0066] 1) In a glass reactor equipped with an electric stirrer, a reflux condenser, and a digital display thermometer, add 100 parts by weight of Wenlun glue, set the stirring rate to 300 rpm, and vacuumize at 120°C under stirring conditions 1h;

[0067] 2) After cooling to about 75°C, add 250 parts by weight of 2,4-toluene diisocyanate and 50 parts by weight of isophorone diisocyanate in turn, then dropwise add 30 parts by weight of triethanolamine and 10 parts by weight of stannous octoate, at 75°C Stirring for 0.5h, the rate of stirring is 300 rpm;

[0068] 3) Add 12 parts by weight of 1,4-butanediol, 100 parts by weight of acetone and 10 parts by wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com