External wall insulation material and preparation method thereof

A technology for external wall insulation and thermal insulation boards, applied in thermal insulation, manufacturing tools, building components, etc., can solve problems such as flammability, toxicity, and toxic smoke, and achieve the effect of improving strength and stability and improving fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

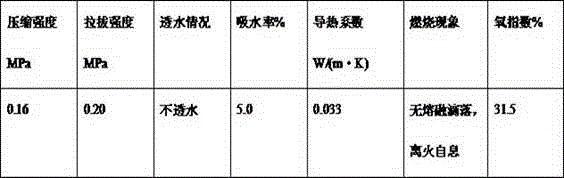

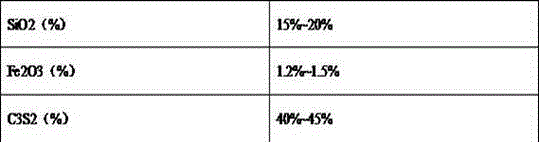

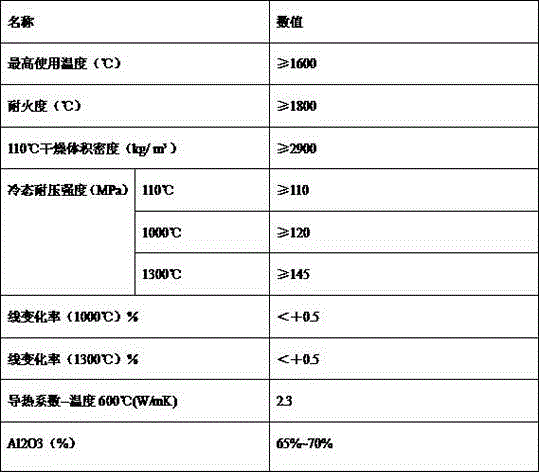

[0023] Pore size distribution and total void volume of special castable layer compared with ordinary castable layer (table)

[0024]

[0025] Conclusion: The pore size distribution of special castables is smaller than that of ordinary castables. With the increase of high-purity ultrafine alumina (ultrafine powder) content, the apparent porosity and median diameter of castables after heat treatment at different temperatures decrease rapidly. It can be seen that The addition of ultra-fine powder can fill the gaps between the castable aggregates, making them smaller or even disappear, making the material more dense, and the median diameter of the pores also becomes smaller.

[0026] The compressive strength of the castable layer is related to the overall porosity gauge, the smaller the porosity, the greater the strength. The total porosity of the special pouring material layer is smaller than that of the ordinary pouring material layer, so the strength of the special pouring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com