Water permeable brick and preparation method thereof

A technology of permeable bricks and permeable surface layers, applied in the field of building materials, can solve problems such as poor recovery of urban groundwater, impact on urban water balance, deterioration of living environment, etc., and achieve the effects of improving water permeability, reducing processing costs, and improving water permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

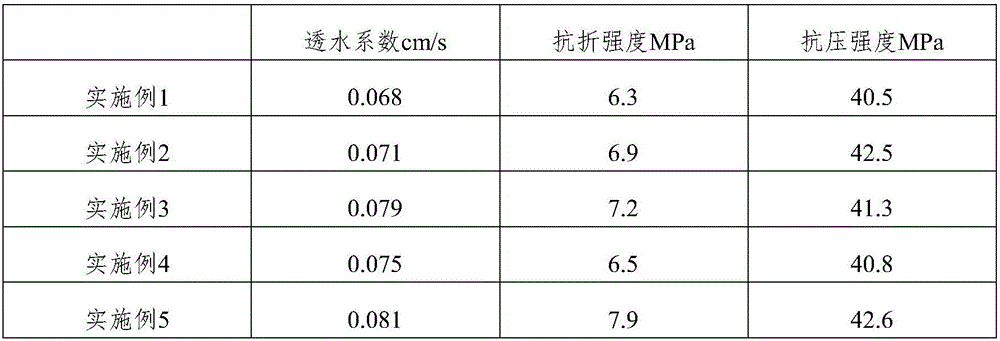

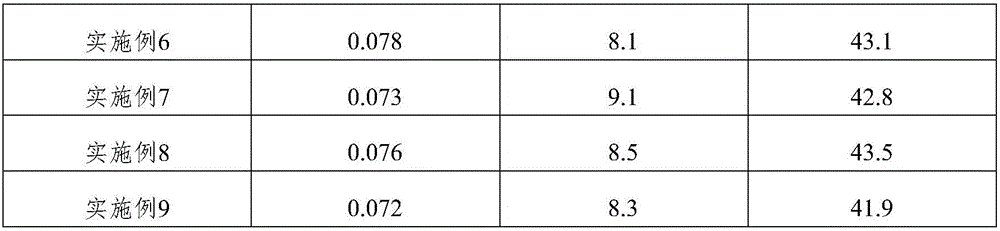

Examples

preparation example Construction

[0031] For the embodiment of the permeable brick preparation method, it specifically includes the following steps on the basis of the above-mentioned embodiments:

[0032] (1) Preparation of a permeable base: after mixing the aggregate and clay evenly, stirring, aging, and extruding to obtain a permeable base;

[0033] (2) Preparation of a permeable surface layer: After mixing the aggregate and clay evenly, stirring, aging, and extruding to obtain a permeable surface layer;

[0034](3) Prepare permeable bricks: set a hole on the upper surface of the permeable base layer, and set a T-shaped hook corresponding to the hole on the lower surface of the permeable surface layer, and squeeze the T-shaped hook into the hole, so that the permeable base layer and the permeable layer The surface layers are closely bonded together and form a whole body to obtain a green body; the green body is dried by infrared radiation for 10 minutes, and the temperature is controlled by infrared radiati...

Embodiment 1

[0042] A permeable brick, comprising a permeable base layer and a permeable surface layer, the permeable base layer and the permeable surface layer are tightly fitted together as a whole through a connecting piece, the connecting piece is to set a hole on the upper surface of the permeable base layer, set a T-shaped hook on the permeable surface layer, and The T-shaped hook can just enter the hole, so that the permeable base layer and the permeable surface layer are closely bonded as a whole, avoiding the staggered phenomenon caused by the setting of the two-layer structure, and improving the quality of the permeable brick; and making the permeable brick between the two-layer structure Capillary water channels are formed between them to improve the water permeability, and it can also effectively enhance the water retention performance of the permeable bricks to prevent water vapor from being directly emitted into the air.

[0043] Carry out in the following manner in its prepar...

Embodiment 2

[0050] On the basis of Example 1, the others are the same as in Example 1. In the preparation process of the permeable base, aggregate and clay are mixed uniformly according to the mass ratio of 2.7:1;

[0051] In the preparation process of the permeable surface layer, the aggregate and clay are uniformly mixed according to the mass ratio of 1.9:0.9. For the permeable base, the aggregate is 0.4-1mm sand, and the moisture content of the clay is 40%. For the permeable surface layer, the aggregate is 0.4-0.9mm sand, and the moisture content of the clay is 35%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com