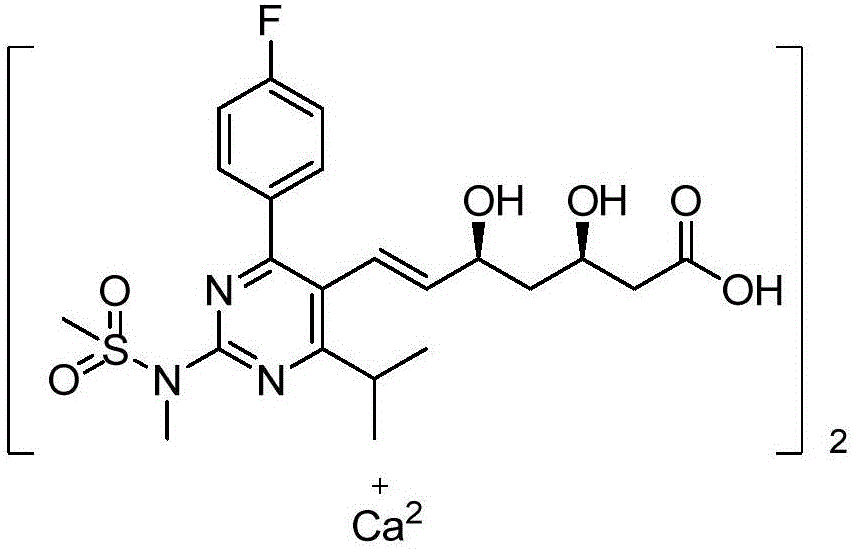

Preparation method of novel rosuvastatin calcium intermediate

A technology of rosuvastatin calcium and intermediates, applied in the field of medicinal chemistry, can solve the problems of long reaction steps, post-treatment of toxic and harmful chemical reagents, cumbersome problems, etc., and achieve the effects of mild chemical reaction conditions, three wastes treatment, and three wastes easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

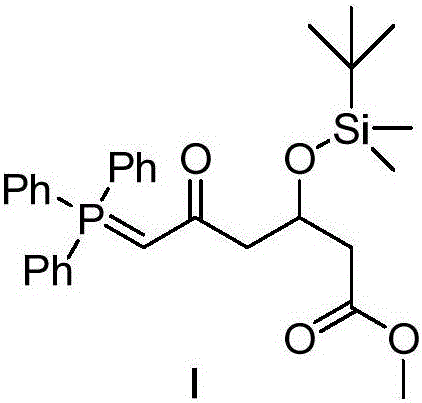

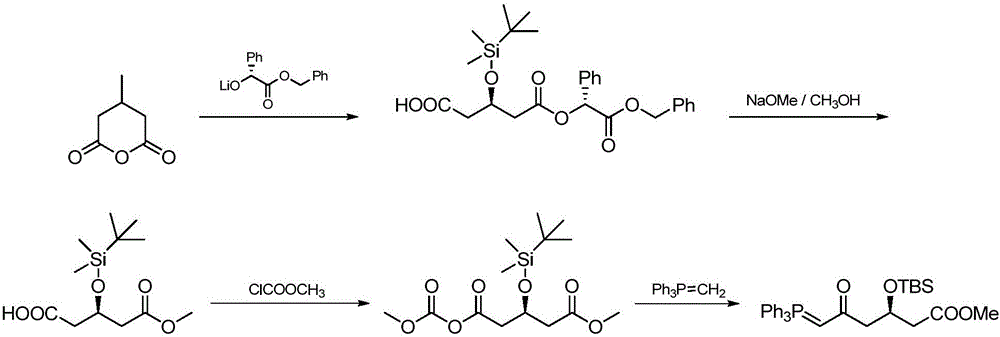

Method used

Image

Examples

Embodiment 1

[0046] Example 1: Preparation of (R)-methyl 3-(tert-butyldimethylsilyloxy)-5-(1H-imidazol-1-yl)-5-oxopentanoic acid methyl ester (compound II)

[0047]

[0048] Put 30.0g 108.5mmol of compound III and 150ml of dichloromethane into a three-necked reaction flask, stir to dissolve. 18.5 g 114.1 mmol of carbonyldiimidazole was added in batches at a controlled temperature of 20-30°C. Stir the reaction for 2-3 hours, take a sample and control it until the residual amount of compound III in the reaction liquid is ≤0.5%, and the reaction is completed.

[0049] The above reaction solution was added to a flash silica gel column for column purification, and the eluate was collected. Concentrate under reduced pressure to remove the solvent to obtain 31.9 g of a yellow oil. Yield 90.0%, GC purity 95.0%.

Embodiment 2

[0050] Example 2: Preparation of (R)-methyl 3-(tert-butyldimethylsilyloxy)-5-(1H-imidazol-1-yl)-5-oxopentanoic acid methyl ester (compound II)

[0051]

[0052] Put 30.0g 108.5mmol of compound III and 150ml of dichloromethane into a three-necked reaction flask, stir to dissolve. 35.2 g 217.1 mmol of carbonyldiimidazole was added in batches at a controlled temperature of 20-30°C. Stir the reaction for 2-3 hours, take a sample and control it until the residual amount of compound III in the reaction liquid is ≤0.5%, and the reaction is completed.

[0053] The above reaction solution was added to a flash silica gel column for column purification, and the eluate was collected. Concentrate under reduced pressure to remove the solvent to obtain 34.0 g of a yellow oil. The pure yield is 84.0%, and the GC purity is 88.0%.

Embodiment 3

[0054] Example 3: Preparation of (R)-methyl 3-(tert-butyldimethylsilyloxy)-5-(1H-imidazol-1-yl)-5-oxopentanoic acid methyl ester (compound II)

[0055]Put 30.0g 108.5mmol of compound III and 150ml of dichloromethane into a three-necked reaction flask, stir to dissolve. 40.5g 249.6mmol of carbonyldiimidazole was added in batches under temperature control at 20-30°C. Stir the reaction for 2-3 hours, take a sample and control it until the residual amount of compound III in the reaction liquid is ≤0.5%, and the reaction is completed.

[0056] The above reaction solution was added to a flash silica gel column for column purification, and the eluate was collected. Concentrate under reduced pressure to remove the solvent to obtain 34.5 g of a yellow oil. The pure yield is 80.0%, and the GC purity is 83.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com