A solvent-resistant, high-toughness, flame-retardant pc/abs composition

A technology of high toughness and composition, applied in the field of flame retardant PC/ABS composition, high toughness and solvent resistance, can solve problems such as unfavorable material properties, negative effects on material toughness and solvent resistance, and avoid small molecular substances. Precipitation, low cost, and the effect of improving flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

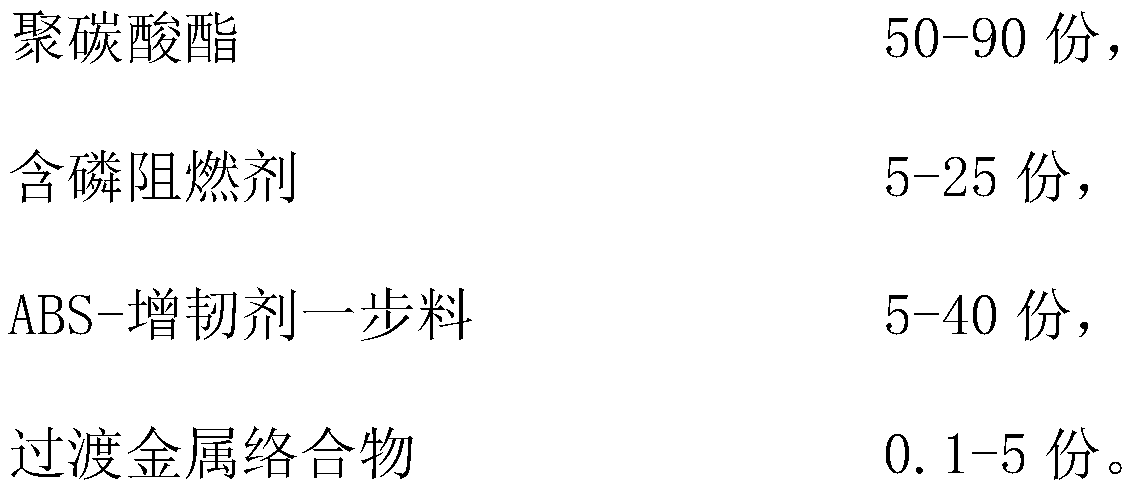

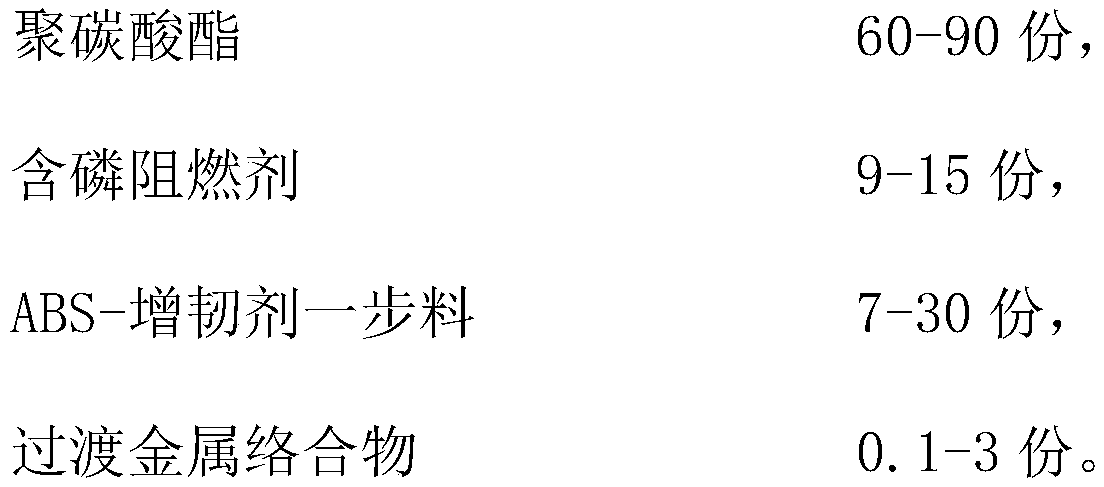

Method used

Image

Examples

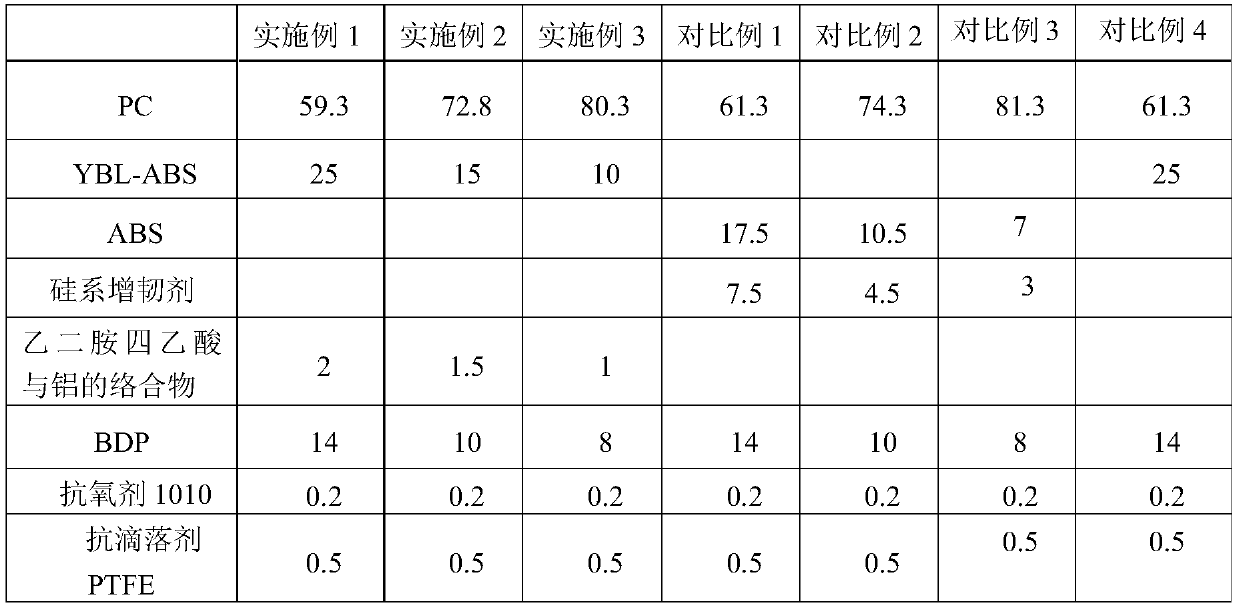

Embodiment 1

[0031] A solvent-resistant, high-toughness, flame-retardant PC / ABS composition, the composition is made of raw materials comprising the following parts by weight: 59.3 parts of polycarbonate, 14 parts of BDP, 25 parts of ABS-toughening agent one-step material, B 2 parts of complexes of diaminetetraacetic acid and aluminum. The ABS-toughening agent one-step material is made of the following raw materials in parts by weight: 70 parts of ABS and 30 parts of silicon-based toughening agent.

[0032] The number average molecular weight of the polycarbonate is 23000. The ABS is the bulk method ABS.

[0033] Described ABS-toughening agent one-step material is made by the method comprising the following steps:

[0034] (1) Put the ABS and the toughening agent into the high mixer and mix for 3 minutes to obtain the premix;

[0035] (2) Put the premix into the main feeding port of the twin-screw extruder, extrude, inject liquid water into the third section and the fifth section of the...

Embodiment 2

[0039] A solvent-resistant, high-toughness, flame-retardant PC / ABS composition, which is made of the following raw materials in parts by weight: 72.8 parts of polycarbonate, 10 parts of BDP, 15 parts of ABS-toughener one-step material 1.5 parts of complexes of amine tetraacetic acid and aluminum. The ABS-toughening agent one-step material is made of the following raw materials in parts by weight: 70 parts of ABS and 30 parts of silicon-based toughening agent.

[0040] The number average molecular weight of the polycarbonate is 23000. The ABS is the bulk method ABS.

[0041] Described ABS-toughening agent one-step material is made by the method comprising the following steps:

[0042] (1) Put the ABS and the toughening agent into the high mixer and mix for 3 minutes to obtain the premix;

[0043] (2) Put the premix into the main feeding port of the twin-screw extruder, extrude, inject liquid water into the third section and the fifth section of the screw barrel of the twin-s...

Embodiment 3

[0047] A solvent-resistant, high-toughness, flame-retardant PC / ABS composition, the composition is made of raw materials comprising the following parts by weight: 80.3 parts of polycarbonate, 8 parts of BDP, 10 parts of ABS-toughener one-step material, B 1 part of complex compound of diaminetetraacetic acid and aluminum. The ABS-toughening agent one-step material is made of the following raw materials in parts by weight: 70 parts of ABS and 30 parts of silicon-based toughening agent.

[0048] The number average molecular weight of the polycarbonate is 23000. The ABS is the bulk method ABS.

[0049] Described ABS-toughening agent one-step material is made by the method comprising the following steps:

[0050] (1) Put the ABS and the toughening agent into the high mixer and mix for 3 minutes to obtain the premix;

[0051] (2) Put the premix into the main feeding port of the twin-screw extruder, extrude, inject liquid water into the third section and the fifth section of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com