Superhydrophobic coating prepared by using graphene three-dimensional aggregates and its synthesis method and application

A super-hydrophobic coating, graphene technology, applied in the coating, paper coating, water repellent addition and other directions, can solve the problems of poor tolerance, no universality, complex construction method, etc., and the method is simple The effect of opposite sex, wide application and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

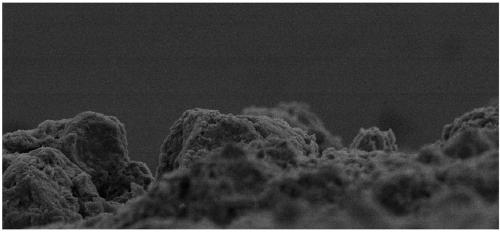

[0020] Grind the three-dimensional graphene aggregates, mix its powder, Nafion solution, and water to obtain a uniformly mixed coating, and apply it to the surface of the glass material to convert it into a super-hydrophobic surface.

[0021] Such as figure 1 As shown, the coating obtained by the present invention is a black uniform and stable dispersion.

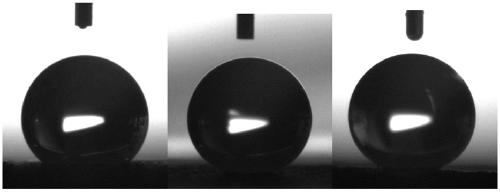

[0022] Such as figure 2 As shown, the surfaces obtained after coating (glass, printing paper, nickel mesh), although the substrates are different, they are all superhydrophobic surfaces, and the contact angles are all greater than 150°.

Embodiment 2

[0024] Grind the three-dimensional graphene aggregates, mix its powder, Nafion solution, and ethanol to obtain a uniformly mixed coating, and apply it to the surface of the glass material to convert it into a super-hydrophobic surface.

Embodiment 3

[0026] Grind the three-dimensional graphene aggregates, mix its powder, inorganic resin solution, and ethanol to obtain a uniformly mixed coating, and apply it to the surface of the glass material to convert it into a super-hydrophobic surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com