A kind of antifouling flashover superhydrophobic self-cleaning coating and preparation method thereof

A super-hydrophobic and self-cleaning technology, applied in antifouling/underwater coatings, fireproof coatings, conductive coatings, etc., can solve the problems of complicated preparation process, low production efficiency and high production cost, and achieve simple preparation process and high production efficiency High, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

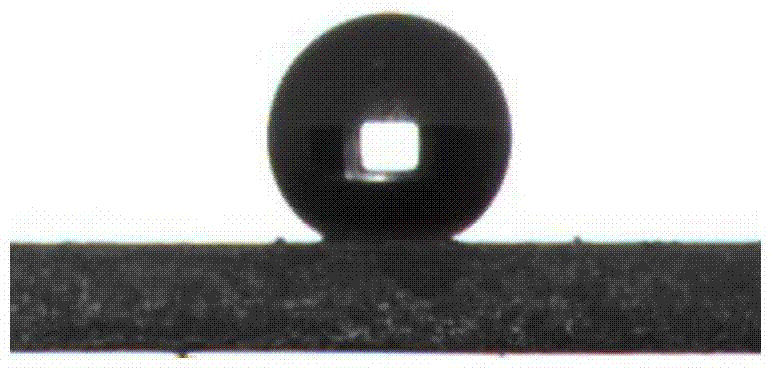

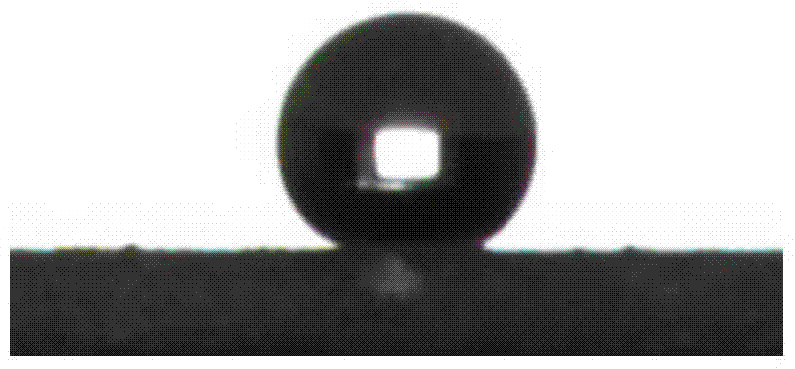

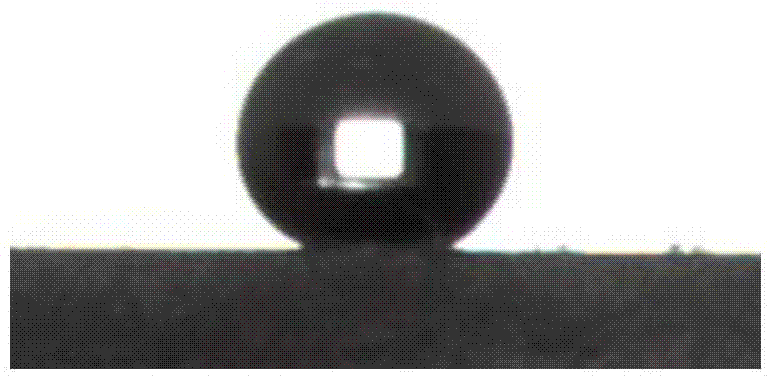

Image

Examples

preparation example Construction

[0033] The preparation method of the antifouling flashover superhydrophobic self-cleaning coating of the present invention is characterized in that silicone glass glue, polyvinylidene fluoride powder, titanium dioxide and aluminum hydroxide are first added to the organic solvent, and fully stirred to make a mixed dispersion , during construction, the dispersion liquid is evenly coated on the surface of the base material, and the anti-fouling flashover super-hydrophobic self-cleaning coating can be obtained.

[0034] The silicone glass glue used in the present invention is neutral and acidic silicone glass glue. The curing time of neutral silicone glass glue is longer, and its bonding ability is weaker than that of acidic silicone glass glue. Therefore, acidic silicone glass glue is preferably used. Its consumption is 5-20% of that of the organic solvent. If the amount of silicone glass glue is too small, it will easily cause low viscosity of the dispersion and uneven applicati...

Embodiment 1

[0041] The antifouling flashover superhydrophobic self-cleaning coating of the present embodiment comprises following components:

[0042] Acidic silicone glass glue, polyvinylidene fluoride powder particles with an average particle size of 250 nanometers, photocatalyst titanium dioxide, anti-arc agent aluminum hydroxide and organic solvent tetrahydrofuran, the silicone glass glue is 7wt% of the organic solvent, so The polyvinylidene fluoride powder particles are 10wt% of the silicone glass glue, the photocatalyst is 35wt% of the silicone glass glue, and the anti-arc agent is 10wt% of the silicone glass glue. The density of the acidic silicone glass glue is 1.2g·cm -3 , The tensile strength is 50MPa, and the elongation is 155%.

[0043] The preparation method of the above-mentioned antifouling flashover superhydrophobic self-cleaning coating comprises the following steps: adding silicone glass glue into an organic solvent, adding polyvinylidene fluoride powder particles, phot...

Embodiment 2

[0046] The antifouling flashover superhydrophobic self-cleaning coating of the present embodiment comprises following components:

[0047] Acidic silicone glass glue, polyvinylidene fluoride powder particles with an average particle size of 2 nanometers, photocatalyst titanium dioxide, arc-resistant agent aluminum hydroxide and organic solvent tetrahydrofuran, the silicone glass glue is 5wt% of the organic solvent, so The polyvinylidene fluoride powder particles are 25wt% of the silicone glass glue, the photocatalyst is 20wt% of the silicone glass glue, and the anti-arc agent is 5wt% of the silicone glass glue. The density of the acidic silicone glass glue is 1.2g·cm -3 , The tensile strength is 50MPa, and the elongation is 155%.

[0048] The preparation method of the above-mentioned antifouling flashover superhydrophobic self-cleaning coating comprises the following steps: adding silicone glass glue into an organic solvent, adding polyvinylidene fluoride powder particles, ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com