A kind of ceramic ink with good stability and preparation method thereof

A ceramic ink technology with good stability, applied in the field of ink, can solve the problems of limited application, unstable color rendering, easy precipitation, etc., and achieve the effects of not easy precipitation, improved color hair rate, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

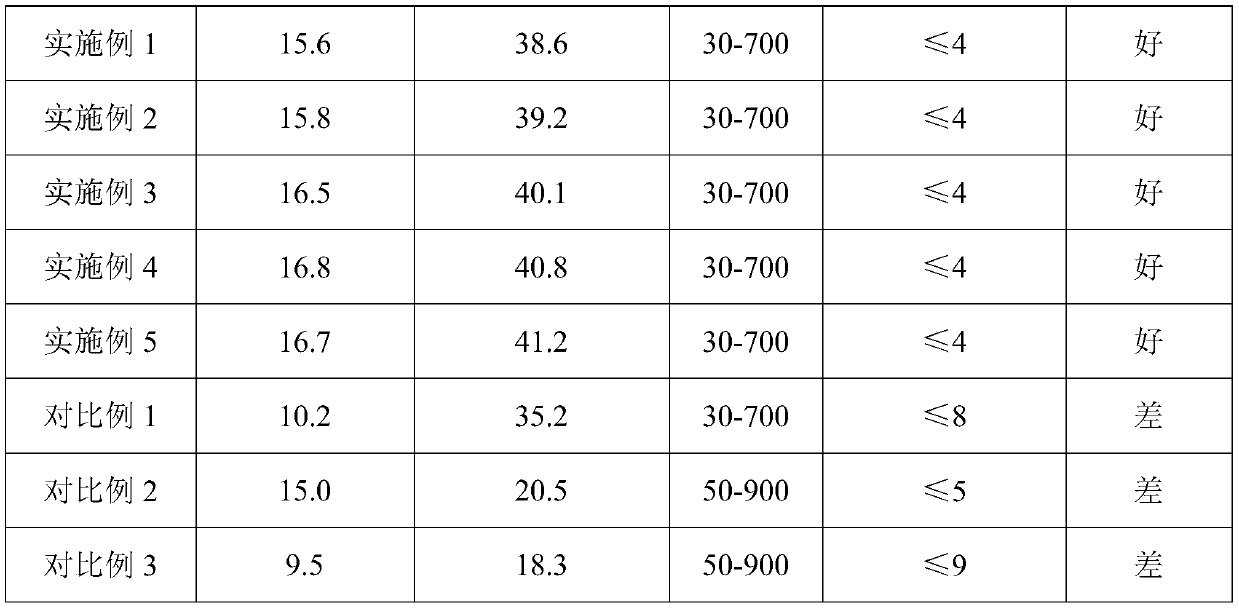

Examples

Embodiment 1

[0020] In the embodiment of the present invention, a ceramic ink with good stability is composed of the following raw materials in parts by weight: 9 parts of polytetrafluoroethylene, 1 part of pigment, 5 parts of isopropyl palmitate, 2,6-dihydroxypyridine 3 parts of -4-carboxylic acid, 2 parts of dimethyl carbonate, 11 parts of titanium dioxide, 40 parts of 50% ethanol solution.

[0021] Mix isopropyl palmitate with half weight of 50% ethanol solution to prepare isopropyl palmitate solution; mix 2,6-dihydroxypyridine-4-carboxylic acid with the other half weight of 50% ethanol solution , The 2,6-dihydroxypyridine-4-carboxylic acid solution was prepared. The polytetrafluoroethylene and isopropyl palmitate solution were mixed, and then heated and stirred for 38 minutes at a temperature of 56° C., and then dimethyl carbonate was added dropwise while stirring. The addition was completed in 15 minutes, and mixture A was prepared. Grind the pigment and the titanium dioxide, then add t...

Embodiment 2

[0023] In the embodiment of the present invention, a ceramic ink with good stability is composed of the following raw materials in parts by weight: 17 parts of polytetrafluoroethylene, 5 parts of pigment, 12 parts of isopropyl palmitate, 2,6-dihydroxypyridine 7 parts of -4-carboxylic acid, 6 parts of dimethyl carbonate, 19 parts of titanium dioxide, 48 parts of 50% ethanol solution.

[0024] Mix isopropyl palmitate with half weight of 50% ethanol solution to prepare isopropyl palmitate solution; mix 2,6-dihydroxypyridine-4-carboxylic acid with the other half weight of 50% ethanol solution , The 2,6-dihydroxypyridine-4-carboxylic acid solution was prepared. The polytetrafluoroethylene and isopropyl palmitate solution were mixed, and then heated and stirred at a temperature of 56° C. for 40 minutes, and then dimethyl carbonate was added dropwise while stirring. The addition was completed in 15 minutes to obtain a mixture A. Grind the pigment and the titanium dioxide, then add the ...

Embodiment 3

[0026] In the embodiment of the present invention, a ceramic ink with good stability is composed of the following raw materials in parts by weight: 11 parts of polytetrafluoroethylene, 2 parts of pigment, 7 parts of isopropyl palmitate, 2,6-dihydroxypyridine 4 parts of -4-carboxylic acid, 3 parts of dimethyl carbonate, 13 parts of titanium dioxide, 42 parts of 50% ethanol solution.

[0027] Mix isopropyl palmitate with half of the volume concentration of 50% ethanol solution to prepare isopropyl palmitate solution; mix 2,6-dihydroxypyridine-4-carboxylic acid with the other half of the volume concentration Mix with 50% ethanol solution to prepare 2,6-dihydroxypyridine-4-carboxylic acid solution. The polytetrafluoroethylene and isopropyl palmitate solution were mixed, and then heated and stirred for 39 minutes at a temperature of 56° C., and then dimethyl carbonate was added dropwise while stirring. The addition was completed in 15 minutes to obtain a mixture A. Grind the pigment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com