Jack oil used at ultralow temperature

A jack and ultra-low temperature technology, applied in the field of jack oil, can solve problems such as failure to work normally, achieve superior work performance, improve service life, and strengthen the effect of viscosity index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

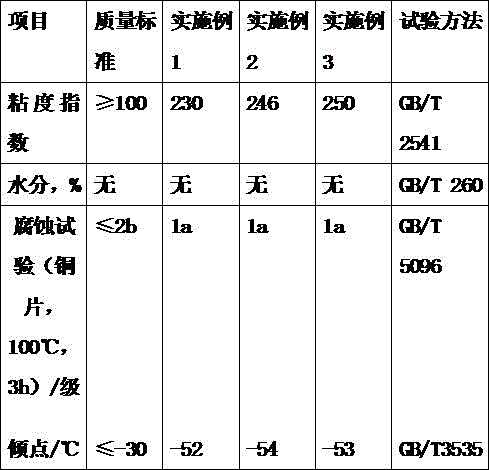

Examples

Embodiment 1

[0015] A kind of jack oil used at ultra-low temperature, which is made of the following components by weight: 99 parts of hydrogenated tail oil, 0.1 part of antirust agent, 0.2 part of antioxidant, and 0.7 part of functional agent, wherein the functional agent consists of the following components by weight Divided into: 60 parts of 1-adamantanol, 10 parts of 3-nonanol, 6 parts of n-tetrabutyl titanate, the preparation method comprises the following steps:

[0016] (1) Add 0.2 times the weight of the sodium chloride solution with a volume fraction of 1% to the hydrogenated tail oil, stir evenly, and then add 0.01 times the weight of the total weight of the mixed solution to it with a volume fraction of 3% hydrogen Sodium oxide solution, after stirring at a speed of 400r / min for 20min, let it stand for 4 hours to remove the aqueous phase solution;

[0017] (2) Add activated carbon 0.02 times its weight to the hydrogenated tail oil treated in step (1), stir evenly, filter and rem...

Embodiment 2

[0022] A kind of jack oil used at ultra-low temperature, made of the following components by weight: 99 parts of hydrogenated tail oil, 0.2 part of antirust agent, 0.3 part of antioxidant, and 0.5 part of functional agent, wherein the functional agent consists of the following components by weight Divided into: 65 parts of 1-adamantanol, 11 parts of 3-nonanol, 7 parts of n-tetrabutyl titanate, the preparation method comprises the following steps:

[0023] (1) Add 0.3 times the weight of the sodium chloride solution with a volume fraction of 1% to the hydrogenated tail oil, stir evenly, and then add 0.02 times the weight of the total weight of the mixed solution with a volume fraction of 3% hydrogen Sodium oxide solution, after stirring at a speed of 400r / min for 20min, let it stand for 4.5 hours to remove the aqueous phase solution;

[0024] (2) Add activated carbon 0.02 times its weight to the hydrogenated tail oil treated in step (1), stir evenly, filter and remove the activ...

Embodiment 3

[0029] A kind of jack oil used at ultra-low temperature, made of the following components by weight: 99 parts of hydrogenated tail oil, 0.2 part of antirust agent, 0.3 part of antioxidant, and 0.5 part of functional agent, wherein the functional agent consists of the following components by weight It is divided into: 70 parts of 1-adamantanol, 12 parts of 3-nonanol, and 8 parts of n-tetrabutyl titanate. The preparation method comprises the following steps:

[0030] (1) Add 0.4 times the weight of the sodium chloride solution with a volume fraction of 1% to the hydrogenated tail oil, stir evenly, and then add 0.03 times the weight of the total weight of the mixed solution to it with a volume fraction of 3% hydrogen The sodium oxide solution was stirred at a speed of 400r / min for 20min, and left to stand for 5 hours to remove the aqueous phase solution;

[0031] (2) Add activated carbon 0.02 times its weight to the hydrogenated tail oil treated in step (1), stir evenly, filter a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com