Production method of Liuzhou river snails rice noodle powder

A production method and technology of snail powder are applied in the production field of snail powder, which can solve the problems of short shelf life and poor quality of dry snail powder, and achieve the effects of prolonging the shelf life, reducing the rate of broken strips, and being convenient to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

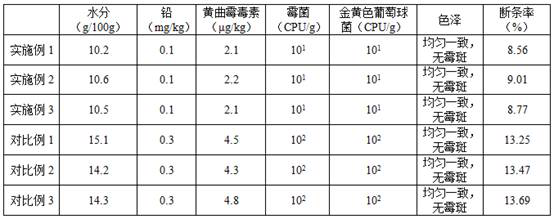

Examples

Embodiment 1

[0023] A kind of production method of snail powder powder, it comprises the following steps:

[0024] (1) Ingredients: Weigh the raw materials according to the following parts by weight: 56 parts of rice, 42 parts of corn, 12 parts of wheat starch, wash the rice and corn with water for 3 times, then perform color selection to remove impurities, and then separate the rice and corn Pulverize and cross 65 mesh sieves to obtain rice flour and corn flour;

[0025] (2) Cooking: Mix rice flour, corn flour and wheat starch evenly, and then steam-cure under a pressure of 0.55 MPa to obtain fully cooked rice flour. The steam-curing temperature is 152°C and the cooking time is 12 minutes;

[0026] (3) Cooling and standing: Cool the rice noodles obtained in step (2) to room temperature at a cooling rate of 2°C / min, and then stand at -8°C for 4 hours;

[0027] (4) Re-steaming: Re-steam the rice noodles treated in step (3) twice, each re-steaming time is 25 minutes, and the interval betwee...

Embodiment 2

[0030] A kind of production method of snail powder powder, it comprises the following steps:

[0031] (1) Ingredients: Weigh the raw materials according to the following parts by weight: 60 parts of rice, 50 parts of corn, 15 parts of wheat starch, wash the rice and corn with water for 4 times, then perform color selection to remove impurities, and then separate the rice and corn Pulverize and cross 80 mesh sieves to obtain rice flour and corn flour;

[0032] (2) Cooking: Mix rice flour, corn flour and wheat starch evenly, and then steam-cure under the condition of 0.6 MPa to obtain fully cooked rice flour. The temperature of steam-curing is 150°C, and the cooking time is 15 minutes;

[0033] (3) Cooling and standing: Cool the rice noodles obtained in step (2) to room temperature at a cooling rate of 1°C / min, and then stand at -10°C for 3 hours;

[0034] (4) Re-steaming: Re-steam the rice noodles processed in step (3) once, each re-steaming time is 30 minutes, and the interva...

Embodiment 3

[0037] A kind of production method of snail powder powder, it comprises the following steps:

[0038] (1) Ingredients: Weigh the raw materials according to the following parts by weight: 50 parts of rice, 40 parts of corn, 10 parts of wheat starch, wash the rice and corn with water for 3 times, then perform color selection to remove impurities, and then separate the rice and corn Pulverize and cross 60 mesh sieves to obtain rice flour and corn flour;

[0039] (2) Cooking: Mix rice flour, corn flour and wheat starch evenly, and then steam-cure under the condition of 0.5 MPa to obtain fully cooked rice flour. The temperature of steam-curing is 160°C, and the cooking time is 10 minutes;

[0040] (3) Cooling and standing: Cool the rice noodles obtained in step (2) to room temperature at a cooling rate of 1.2°C / min, and then stand at -8.5°C for 3.5 hours;

[0041] (4) Re-steaming: Re-steam the rice noodles treated in step (3) for 3 times, each re-steaming time is 20 minutes, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com