A production process of -10# military diesel oil and 5# industrial white oil

An industrial white oil and production process technology, applied in the petroleum industry, hydrocarbon oil treatment products, multi-stage series refining process treatment, etc. Industrial white oil and other problems, to achieve the effect of reducing gum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

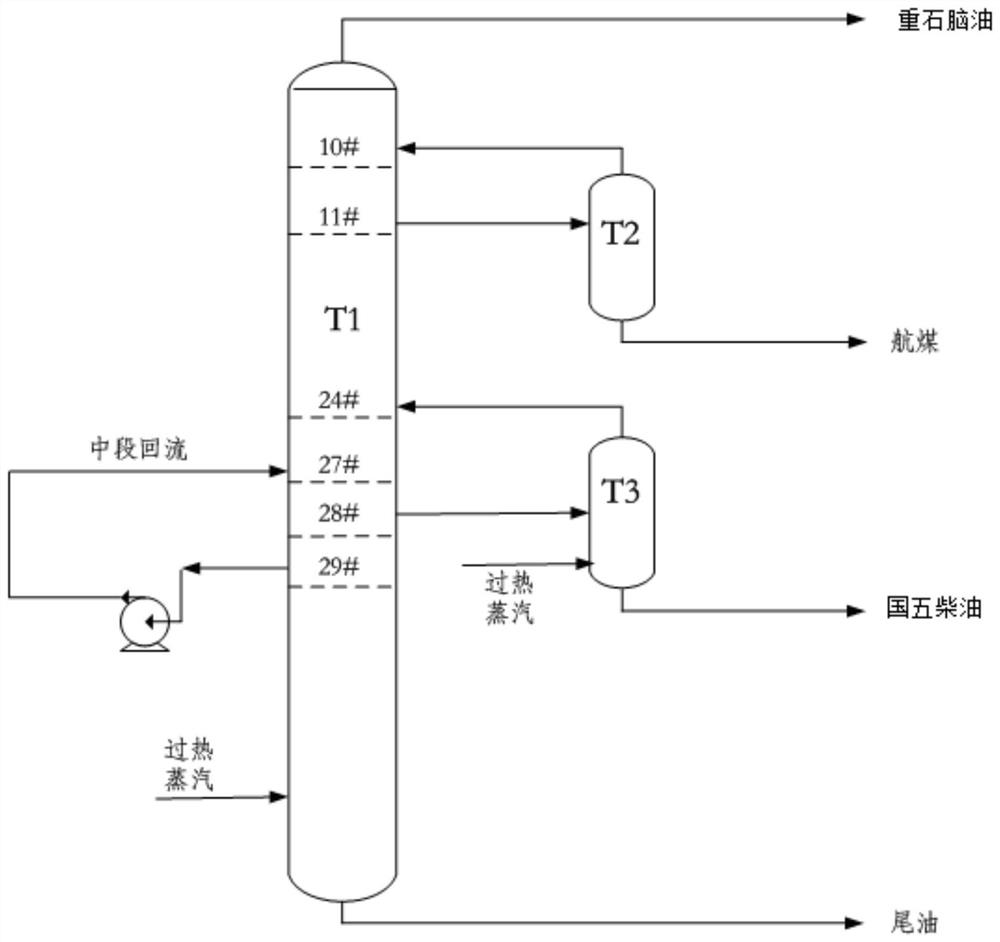

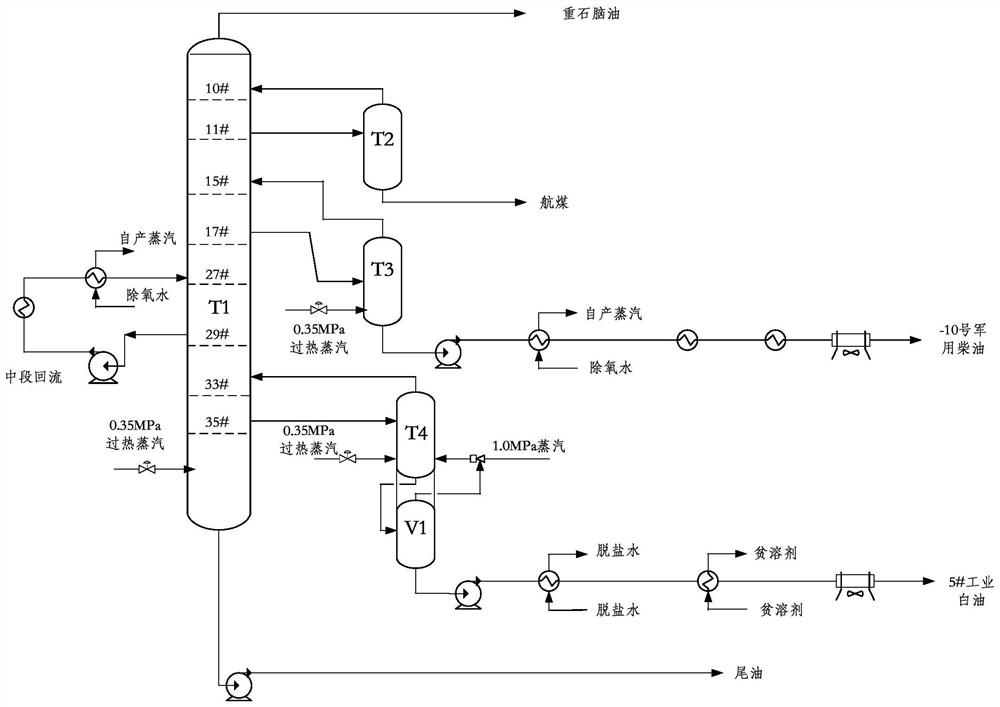

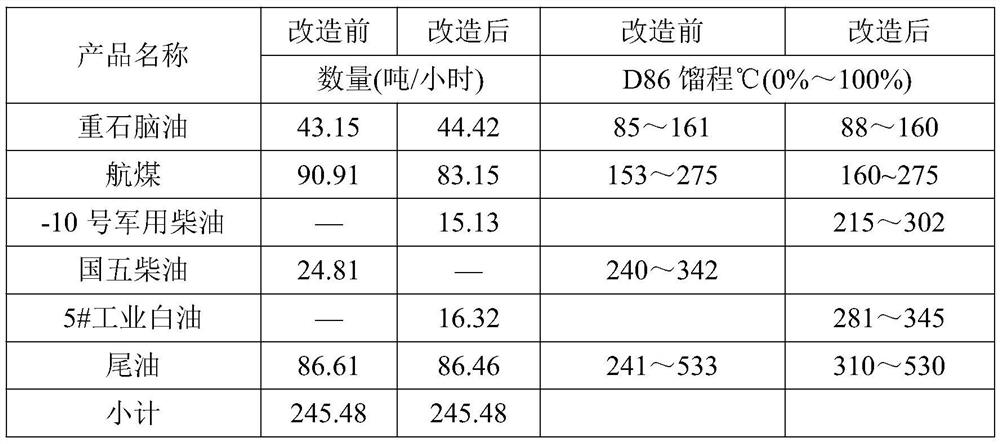

[0029] like figure 2 As shown in , a production process of No. 10 military diesel and high-quality industrial white oil, including the following steps:

[0030] (1) after the pretreatment of the generated oil of hydrocracking, entering the number of trays is to carry out fractionation in the fractionating tower T1 of 54 layers, and at the 17th layer tray of the fractionating tower T1, a diesel oil extraction outlet is opened, and the diesel extraction outlet is There is a diesel extraction pipeline, and the diesel extraction pipeline is connected with a diesel side stripping tower T3. The diesel extracted from the diesel extraction outlet flows into the diesel side stripping tower T3 through the diesel extraction pipeline. After being stripped by the diesel side stripping tower T3, the diesel side stripping tower T3 The oil and gas at the top of the stripping tower T3 is returned to the 15th layer tray of the fractionation tower T1, and the product at the bottom of the diesel...

Embodiment 2

[0062] The difference from Example 1 is that the number of layers of the fractionating tower T1 is 60 layers, and the diesel extraction outlet is set at the 16th layer tray of the fractionating tower T1, and after the diesel side stripping tower T3 is stripped, the diesel side stripping tower is The oil and gas at the top of the T3 tower is returned to the 14th layer tray of the fractionation tower T1.

[0063] A white oil extraction outlet is added at the 34th layer tray of the fractionation tower T1. After being stripped by the white oil side stripper T4, the top gas of the white oil side stripper T4 is returned to the 32nd tray of the fractionation tower T1.

Embodiment 3

[0065] Different from Example 1, the number of trays of the diesel side stripper T3 is 18 layers, and the number of trays of the side stripper of white oil is 18 layers.

[0066] The superheated steam used in the diesel side stripping tower T3 and the white oil side stripping tower T4 is superheated low-pressure steam with a temperature of 380° C. and a pressure of 0.45 MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com