Multidirectional Parallel Tilting Mechanism for Steelmaking Rotary Converter

A multi-directional, steel-making furnace technology, used in the manufacture of converters and other directions, can solve the problems of poor mixing performance of molten iron and alloy materials, poor ability to remove impurities, short life of converter lining, etc., to achieve compact structure, large working space, The effect of high carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

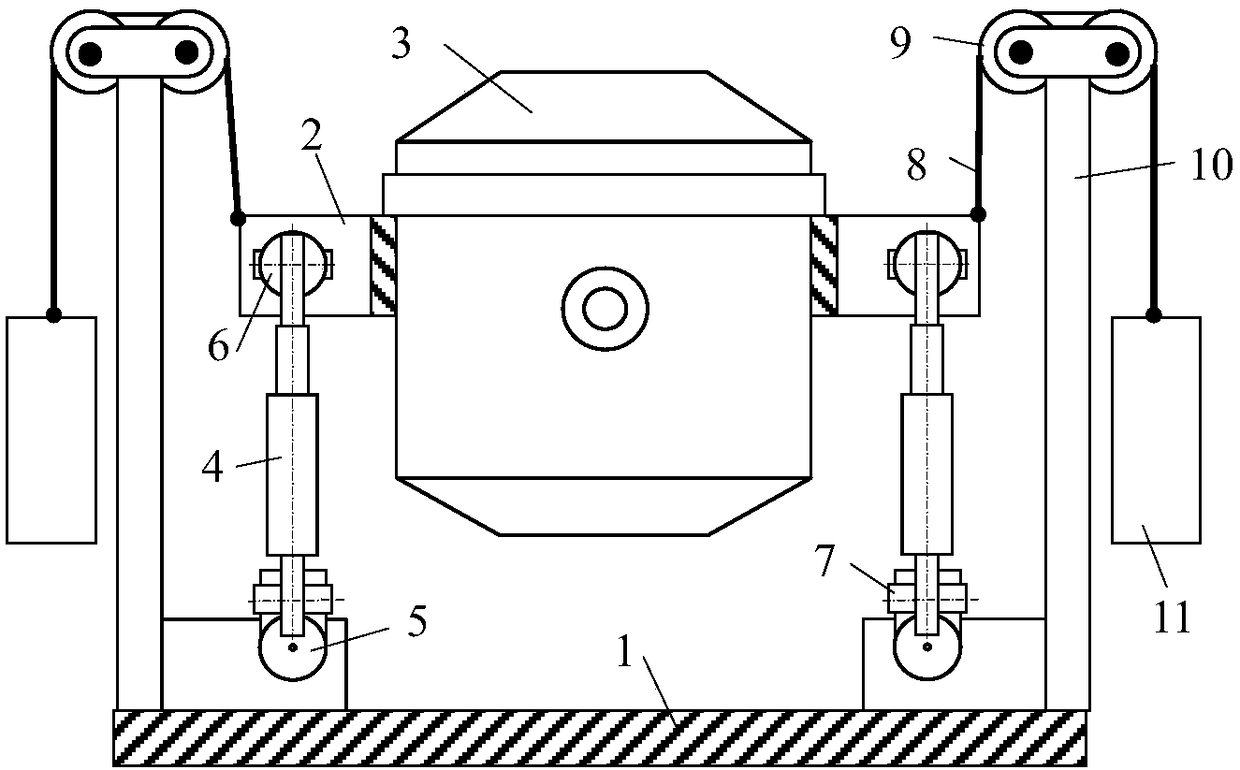

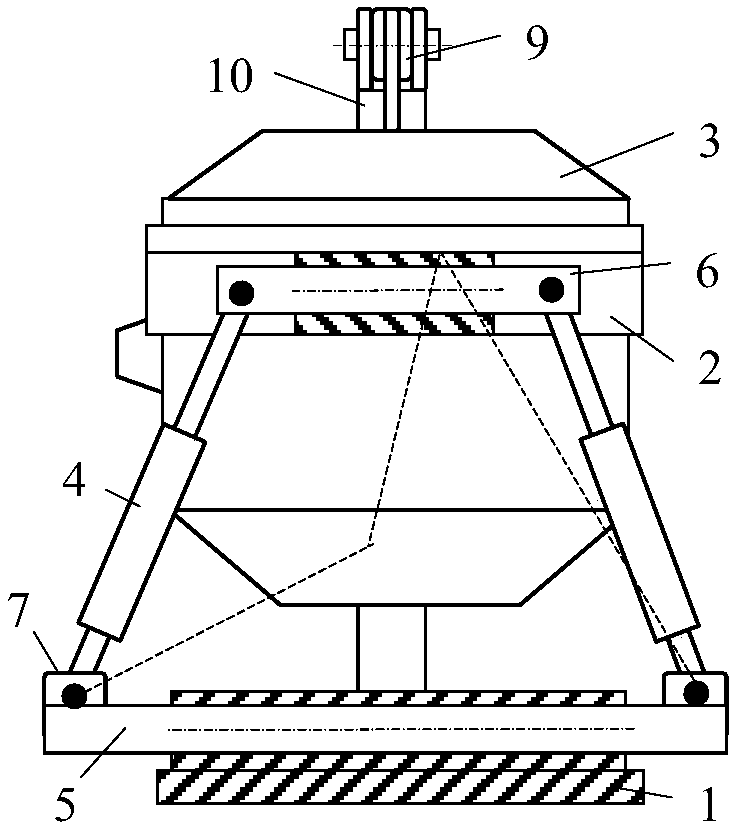

[0016] exist figure 1 with figure 2 In the schematic diagram of the multi-directional parallel swinging mechanism of the steelmaking furnace shown, the steel tapping port of the swinging converter 3 is located in the middle of the furnace body, the swinging converter is fixedly connected with the moving table 2, and its axis line is perpendicular to the moving table, and the two planes with the same structure The double drive branches are distributed parallel and symmetrically on both sides of the rotary furnace, and two counterweight devices with the same structure are symmetrically distributed on the outside of the two plane double drive branches; The horizontal axis, two RPR (rotating pair-moving pair-rotating pair) type linear drive branches and four pin shafts, in which the two ends of the upper horizontal axis 6 and the lower horizontal axis 5 are provided with parallel and orthogonal horizontal axis axes. Through hole, RPR type linear drive branch 4 is a conventional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com