Digital printing sizing agent of suede wool fabric and technology thereof

A technology for digital printing and wool fabrics, applied in the field of printing and dyeing, can solve the problems of insufficient color fastness, influence on fabric quality, long steaming time, etc. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Prepare the slurry in the following parts by weight proportioning:

[0048] Sodium sulfite: 6; Urea: 10; Sodium alginate: 4; DGT-7: 4;

[0049] Penetrant: 5.5; ammonium sulfate: 2.5; glacial acetic acid: 2; water: 66.

[0050] After experiments, the selection and optimization of slurry components are as follows:

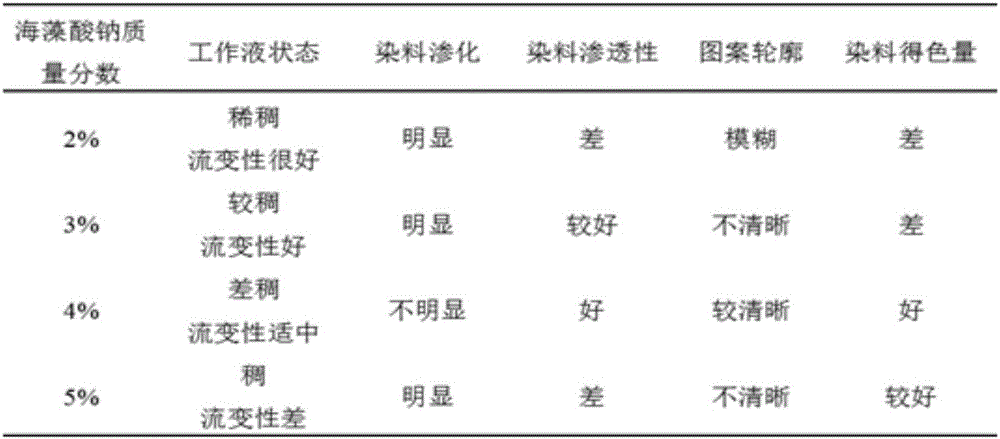

[0051] Table 1 Effect of mass fraction of sodium alginate on digital printing effect

[0052]

[0053] Table 2 The effect of the mass ratio of DGT-7 and sodium alginate on the effect of digital printing

[0054]

[0055] Taking cashmere fabric as an example, the digital printing process is as follows:

[0056] (1) preparation of slurry;

[0057] Add water: add the required amount of water to the beating bucket;

[0058] Turn on the mixer: the blade of the mixer is placed in the center of the pulp bucket, and the height from the bottom of the bucket is 0.5-1 times the diameter of the blade. Turn on the mixer and adjust the speed to 1440r / min;

[005...

Embodiment 2

[0091] Taking cashmere fabric as an example, the ratio of the slurry is as follows:

[0092] Sodium sulfite: 4; Urea: 8; Sodium alginate: 2; DGT-7: 2;

[0093] Penetrant: 4; ammonium sulfate: 2; glacial acetic acid: 1; water: 60.

[0094] The slurry preparation method and digital printing process conditions are the same as in Example 1.

Embodiment 3

[0096] Taking cashmere fabric as an example, the ratio of the slurry is as follows:

[0097] Sodium sulfite: 9; Urea: 12; Sodium alginate: 6; DGT-7: 6;

[0098] Penetrant: 7; ammonium sulfate: 5; glacial acetic acid: 3; water: 72.

[0099] The slurry preparation method and digital printing process conditions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com